Abstract

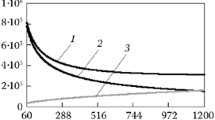

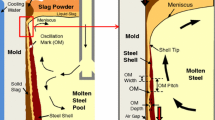

To investigate superheat dissipation in a continuous slab casting machine, mathematical models have been developed to compute fluid flow velocities, temperature distribution within the liquid pool, heat transfer to the inside of the solidifying shell, and its effect on growth of the shell. Three-dimensional (3-D) velocity and heat-transfer predictions compare reasonably with pre-vious experimental measurements and two-dimensional (2-D) calculations. The results indicate that the maximum heat input to the shell occurs near the impingement point on the narrow face and confirm that most of the superheat is dissipated in or just below the mold. Superheat tem-perature and casting speed have the most important and direct influence on heat flux. The effects of other variables, including mold width, nozzle jet angle, and submergence depth, are also investigated. Calculated heat flux profiles are then input to a one-dimensional (1-D) solidifi-cation model to calculate growth of the shell. Shell thickness profiles down the wide and narrow faces are compared with the predictions of conventional heat conduction models and available measurements.

Similar content being viewed by others

References

H. Nakata, M. Ozawa, K. Kinoshita, Y. Habu, and T. Emi:Trans. Iron Steel Inst. Jpn., 1984, vol. 24 (11), pp. 957–65.

K. Saito and M. Tate:Open Hearth Furnace Proc, AIME, Warrendale, PA, 1973, vol. 56, pp. 238–68.

P. Flint:Proc. 73rd Steelmaking Conf., Iron and Steel Society, Warrendale, PA, 1990.

A. Etienne:Proc. 4th Int. Conf. Continuous Casting, Stahl Eisen, Brussels, 1988, vol, 2, pp. 597–608.

I.D. Simpson, L.G. Moore, and C.L. Carey:Proc. 1st European Conf. on Continuous Casting, Associazione Italiana di Metallurgia, Florence, Italy, 1991, vol. 1, pp. 1.435–1.444.

S.J. Chen and T.M. Chen:Proc. 1st European Conf. on Continuous Casting, Associazione Italiana di Metallurgia, Florence, Italy, 1991, vol. 1, pp. 1.455–1.468.

K. Ayata, T. Mori, T. Fujimoto, T. Ohnishi, and I. Wakasugi:Trans. Iron Steel Inst. Jpn., 1984, vol. 24 (11), pp. 931–39.

J. Lait, J.K. Brimacombe, and F. Weinberg:Ironmaking and Steelmaking (Q.), 1974, vol. 2, pp. 90–98.

B. Lally, L. Biegler, and H. Henein:Metall. Trans. B, 1990, vol. 21B, pp. 761–70.

E. Upton, T.R. Satya Rao, P.H. Dauby, and R.C. Knechtges:Iron and Steelmaker, 1988, vol. 15 (5), pp. 51–57.

M. Yao, M. Ichimiya, M. Tamiya, K. Suzuki, K. Sugiyama, and R. Mesaki:Trans. Iron Steel Inst. Jpn., 1984, vol. 24, p. s211.

T. Robertson, P. Moore, and J.F. Hawkins:Ironmaking and Steelmaking, 1986, vol. 13 (4), pp. 195–203.

N. Bessho, R. Yoda. H. Yamasaki, T. Fujii, T. Nozaki, and S. Takatori:Proc. 6th Int. Iron and Steel Congress, Iron and Steel Inst. Japan, Chiyoda-Ku, Tokyo, Nagoya, Japan, 1990, vol. 3, pp. 339–47.

B.G. Thomas and F.M. Najjar:Appl. Mathematical Modelling, 1991, vol. 15, pp. 226–43.

B.G. Thomas, L.M. Mika, and F.M. Najjar:Metall. Trans. B, 1990. vol. 21B, pp. 387–400.

D.E. Hershey: To be presented at75th Steelmaking Conf., Iron and Steel Society, Toronto, ON, Canada, April 5–8, 1992.

R.C. Sussman, M. Burns, X. Huang, and B.G. Thomas: To be presented at75th Steelmaking Conf., Toronto, ON, Canada, April 5–8, 1992.

M.S. Engelman:FIDAP Theoretical Manual—Revision 4.0, Fluid Dynamics International, Inc., Evanston, IL, 1986.

B.E. Launder and D.B. Spalding:Computer Methods Appl. Mech. Eng., 1974, vol. 13, pp. 269–89.

F.M. Najjar, D.E. Hershey, and B.G. Thomas:4th FIDAP Users Conf., Fluid Dynamics International, Inc., Evanston. IL, 1991, pp. 1–55.

C. Offerman:Scand. J. Metall., 1981, vol. 10, pp. 25–28.

B.G. Thomas, A. Moitra, and W.R. Storkman:Proc. 6th Int. Iron Steel Congress, Iron and Steel Inst. Japan, Chiyoda-Ku, Tokyo, Nagoya, Japan, 1990, vol. 3, pp. 348–55.

X. Huang: Ph. D. Thesis, Tsinghua University, China, 1988.

S.V. Patankar:Numerical Heat Transfer and Fluid Flow, McGraw- Hill, New York, NY, 1980.

F. Najjar: Master's Thesis, University of Illinois, Urbana, IL, 1990.

S. Joo and R.I.L. Guthrie:Proc. Int. Symp. Developments in Ladle Steelmaking and Continuous Casting, G. Lawson, ed., Canadian Inst. Min. Metall., Montreal, PQ, Hamilton, Canada, 1990, pp. 264-89.

J. Lipton. W. Kurz, and W. Heinemann:Proc. TMS Fall Meeting, TMS, Warrendale, PA, St. Louis, MO, Oct. 24–28, 1982.

M. Kumada and I. Mabuchi:Trans. Jpn. Soc. Mech. Eng., 1969, vol. 35, pp. 1053–61.

P. Sismanis and S.A. Argyropoulos:Metall. Trans. B, 1988, vol. 19B, pp. 859–70.

B.G. Thomas, F.M. Najjar, and L.J. Mika:Proc. F. Weinberg Int. Svmp. on Solidification Processing, 29th Canadian Inst. Min. Met. Conf., J. Lait and I.V. Samarasekera, eds., Pergamon Press, Toronto, Hamilton, ON, Canada, 1990, pp. 131–45.

E. Hofken, H. Lax, and G. Pietzko:4th Int. Conf. Continuous Casting, Stahl Eisen, Brussels, Belgium, 1988, vol. 2, p. 461.

J. Savage and W.H. Pritchard:J. Iron Steel Inst., 1954, vol. 178, pp. 269–77.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Huang, X., Thomas, B.G. & Najjar, F.M. Modeling superheat removal during continuous casting of steel slabs. Metall Trans B 23, 339–356 (1992). https://doi.org/10.1007/BF02656290

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02656290