Abstract

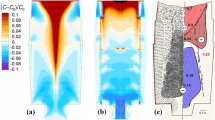

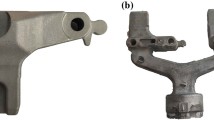

A close examination of the recent developments in the field of computer simulation of solidification process reveals that a combination of both macroscopic and microscopic models is necessary in order to accurately describe the solidification of castings. Currently available macroscopic models include models that describe heat transfer from metal to mold, fluid flow of liquid metal during mold filling, and stress field in the casting. At the microscopic level, the models should include more intricate issues such as solidification kinetics and fluid flow in the mushy zone. Although significant progress has been accomplished over the years in each field, the task of including all of these models into a comprehensive package is far from being complete. This paper describes the state of the art on coupling the macroscopic heat transfer (HT) and microscopic solidification kinetics (SK) models and introduces thelatent heat method as a more accurate method for solving the heat source term in the heat conduction equation. A new method for calculation of fraction of solid evolved during solidification based on computer-aided cooling curve analysis (CA-CCA), as well as a method based on nucleation and growth kinetics laws, is discussed. A new nucleation model based on the concept of instantaneous nucleation, which is used to describe equiaxed eutectic solidification of commercial alloys, has been introduced. It is demonstrated that the instantaneous nucleation model agrees well with the experimental results in terms of cooling curves and of evolution of the fraction of solid during solidification. Validation results are also shown for SK models that are based on CA-CCA coupled with HT models for eutectic Al-Si and gray cast iron alloys.

Similar content being viewed by others

Abbreviations

- A :

-

surface area [m2]

- C p :

-

specific heat [J kg-1 K-1]

- D :

-

liquid diffusivity [m2 s-1]

- K :

-

thermal conductivity [W m-1 K-1]

- K 1 K2,K 3,K 4 :

-

nucleation constants

- I het :

-

heterogeneous nucleation rate [m-3 s-1]

- L :

-

volumetric latent heat of fusion [J m-3]

- L′ total heat evolved at the end of transformation [J kg-1]:

-

Ll′

- heat evolved due to transformation until timet [J kg-1]:

-

N

- number of particles that have already nucleated per unit volume [m-3]:

-

N s

- number of heterogeneous substrates originally available per unit volume [m-3]:

-

N(x, t)

- number of grains per unit volume (grain density) [m−3]:

-

Q L

- latent heat evolved during solidification [J]:

-

Q

- source term or rate of evolution of latent heat [W m−3]:

-

R(x, t)

- average equiaxed grain radius [m]:

-

T

- temperature at a given location in casting [K]:

-

T cc

- temperature at the center of the casting obtained from cooling curve [K]:

-

T zc

- temperature at the center of the casting as calculated from the zero curve [K]:

-

T E

- equilibrium temperature [K]:

-

T o

- ambient temperature [K]:

-

T M

- melting point [K]:

-

T n

- nucleation temperature [K]:

-

V

- volume of sample [m3]:

-

a, b a 1 b 1

- constants:

-

a o , b o , c o

- constants:

-

do, eo

- constants:

-

d

- atomic diameter [m]:

-

fs

- volume fraction of solid:

-

f(δ)

- function of wetting angle between liquid and substrate:

-

h

- heat transfer coefficient [W m-2 K-1]:

-

k

- Boltzman's constant [J K-1]:

-

n′

- number of surface atoms of the substrate per unit volume of liquid [m-3]:

-

ns

- number of atoms in the heterogeneous substrate per unit volume for SiO2 [m-3]:

-

qcc, qzc

- rate of convective heat loss from the casting [W]:

-

rs

- radius of substrate [m]:

-

p

- density [kg m-3]:

-

t

- time [s]:

-

to

- time at the beginning of solidification [s]:

-

ΔGc het

- energy of formation of the critical nucleus [J]:

-

ΔGA

- diffusional activation energy for growth [J]:

-

ΔT

- undercooling [K]:

-

δRN/δt

- nucleation rate [m-3 s-1]:

-

δR/δt

- growth rate [m s-1]:

-

γ

- vibrational frequency [s-1]:

-

μ1

- growth constant [m s"-1 K-2]:

-

μ2

- nucleation constant [m-3 K-2]:

-

σ surface tension [N m-1]

References

D.M. Stefanescu and C.S. Kanetkar:State of the Art of Computer Simulation cf Casting and Solidification Processes, H. Fredriksson, ed., Les Editions de Physique, Paris, 1986, pp. 255–66.

M. Rappaz and D.M. Stefanescu: inSolidification Processing of Eutectics, D.M. Stefanescu, ed., TMS, Warrendale, PA, 1988, pp. 133–51.

C.S. Kanetkar, I.G. Chen, D.M. Stefanescu, and N. El-Kaddah:J. Iron Steel. Inst. Jpn., 1988, vol. 28, pp. 860–68.

I.G. Chen and D.M. Stefanescu:AFS Trans., 1984, vol. 92, pp. 947–64.

M. Rappaz and P. Thevoz:Acta Metall., 1987, vol. 35 (7), pp. 1487–97.

C.S. Kanetkar and D.M. Stefanescu: inModeling of Casting and Welding Processes IV, A.F. Giamei and G.J. Abbaschian, eds., TMS, Warrendale, PA, 1988, pp. 697–708.

C.S. Kanetkar and D.M. Stefanescu:AFS Trans., 1988, vol. 96, pp. 591–98.

D.M. Stefanescu and C. Kanetkar: inComputer Simulation of Microstructural Evolution, DJ. Srolovitz, ed., TMS, Warrendale, PA, 1985, pp. 171–88.

W. Oldfield:ASM Trans., 1966, vol. 59, pp. 945–59.

K.C. Su, I. Ohnaka, I. Yaunauchi, and T. Fukusako: inThe Physical Metallurgy of Cast Iron, H. Fredriksson and M. Hillert, eds., North-Holland, New York, NY, 1984, pp. 181–89.

J.W. Christian:The Theory of Transformation in Metals and Alloys, Pergamon, Oxford, 1975, p. 450.

J.D. Hunt:Mater. Sei. Eng., 1984, vol. 65, pp. 75–83.

P. Thevoz, J.L. Desbioles, and M. Rappaz:Metall. Trans. A, 1989, vol. 20A, pp. 311–22.

M.C. Flemings:Solidification Processing, McGraw-Hill Book Co., New York, NY, 1974, p. 357.

W.A. Johnson and R.F. Mehl:Trans. AIME, 1939, vol. 135, pp. 416–58.

M.F. Basdogan, V. Kondic, and G.H.J. Bennett:AFS Trans., 1982, vol. 90, pp. 263–73.

W. Patterson and D. Ammann:Giesserei, 1959, no. 1, p. 1247.

D.M. Stefanescu: inThe Physical Metallurgy of Cast Iron, H. Fredriksson and M. Hillert, eds., North-Holland, New York, NY, 1984, pp. 151–62.

M. Rappaz:Int. Mater. Rev., 1989, vol. 34 (3), p. 93.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Stefanescu, D.M., Upadhya, G. & Bandyopadhyay, D. Heat transfer-solidification kinetics modeling of solidification of castings. Metall Trans A 21, 997–1005 (1990). https://doi.org/10.1007/BF02656584

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02656584