Abstract

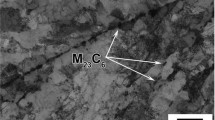

Temper embrittlement of 2.25 Cr-1 Mo steel doped with P and Sn was studied systematically. Carbide extraction by electrolysis, X-ray diffraction, transmission (replica) electron microscopy, chemical analysis of the matrix, and scanning Auger microprobe analysis were conducted to determine the effect of carbide precipitation and subsequent variation of the Mo concentration in solution on the segregation of P. These analyses were correlated with the ductile-to-brittle transition temperature (measured by use of a slow-bend test), as well as hardness measurements and fractographic information obtained by scanning electron microscopy. The results indicate that the principal role of Mo is to suppress embrittlement by scavenging of P, presumably by a Mo-P compound formation, thereby diminishing P segregation. However, due to the stronger interaction between Mo and C, Mo is precipitated in an M2C carbide during tempering or aging, and the matrix is depleted of Mo. The P thereby released segregates at a rate consistent with the rate of M2C precipitation. At a Mo concentration >0.7 pct the beneficial effect of Mo is decreased due to enhanced M2C precipitation, the content of Mo in solution remaining essentially constant. The M2C is formed at the expense of Cr-rich M7C3; this results in more Cr in solution, thereby permitting more Cr-P cosegregation, and embrittlement increases. Tin was found not to produce temper embrittlement in this steel when present at concentrations up to 0.04 pct.

Similar content being viewed by others

References

R. H. Greaves and J. A. Jones:J. Iron Steel Inst., 1925, vol. 111, p. 231.

H. Jolivet and G. Vidal:Rev. Met., 1944, vol. 41, p. 378.

G. Vidal:Rev. Met., 1945, vol. 42, p. 149.

C. J. McMahon, Jr., A. K. Cianelli, and H. C. Feng:Met. Trans. A, 1977, vol. 8A, p. 1055.

A. E. Powers:Trans. ASM, 1956, vol. 48, p. 149.

A. E. Powers:J. Iron Steel Inst., 1957, vol. 186, p. 323.

T. Wada and W. C. Hagel:Met. Trans. A, 1976, vol. 7A, p. 1419.

P. L. Gruzin and V. V. Minal:Fiz. Met. Metalloved., 1964, vol. 17, p. 62.

M. P. Seah:Acta Met., 1977, vol. 25, p. 345.

M. L. Wayman, P. Dumoulin, and M. Guttmann:Can. Metall. Quart., 1978, vol. 18, p. 632.

B. J. Schulz and C. J. McMahon, Jr.: ASTM STP 499, p. 104, 1972.

G. A. Dreyer, D. C. Austen, and W. D. Smith:Met. Progr., 1964, vol. 86, p. 116.

B. S. Lement, B. L. Averbach, and M. Cohen:Trans. ASM, 1954, vol. 46, p. 851.

W. Koch and H. Sundermann:J. Iron Steel Inst., 1958, vol. 190, p. 373.

R. W. Gurry, J. Christakso, and C. D. Stricker:Trans. ASM, 1957, vol. 50, p. 105.

K. W. Andrews and H. Hughes: ASTM STP 393, p. 3, 1966.

D. J. Dyson and K. W. Andrews:J. Iron Steel Inst., 1969, vol. 207, p. 208.

T. M. F. Ronald and C. Bodsworth:J. Iron Steel Inst., 1965, vol. 203, p. 252.

D. J. Dyson and K. W. Andrews:J. Iron Steel Inst., 1964, vol. 202, p. 325.

R. Stockdale and R. Binns: Private communication, Climax Molybdenum Co., Ann Arbor, Mich., 1977.

ASTM Standards: Chemical Analysis of Metals; Sampling and Analysis of Metal Bearing Ores, Part 32, ASTM, Phila, PA, 1969.

R. G. Baker and J. Nutting:J. Iron Steel Inst., 1959, vol. 192, p. 257.

J. Yu and C. J. McMahon, Jr.:Met. Trans. A, 1980, vol. 11A, p. 291.

R. A. Mulford, C. J. McMahon, Jr., D. P. Pope, and H. C. Feng:Met. Trans. A, 1976, vol. 7A, p. 1183.

R. Bruscato:Weld. J., 1970, vol. 49, p. 148.

J. Watanabe, Y. Shindo, Y. Murakami, T. Adachi, and S. Ajiki: Presented at 29th ASME Meeting, 1974.

J. E. Bridge, Jr., G. N. Maniar, and T. U. Phillips:Met. Trans., 1971, vol. 2, p. 2209.

H. Morikawa, H. Komatsu, and M. Tanino:J. Electron Microsc., 1973, vol. 22, p. 99.

J. R. Low, Jr., D. F. Stein, A. M. Turkalo, and R. P. Laforce:Trans. TMS-AIME, 1968, vol. 242, p. 14.

C. J. McMahon, Jr.: ASTM STP 407, p. 127, 1968.

J. M. Capus:J. Iron Steel Inst., 1962, vol. 200, p. 922.

S. Takayama, T. Ogura, S. C. Fu, and C. J. McMahon, Jr.: Unpublished research, Univ. of Penn., Phila., PA, 1979.

A. K. Cianelli, H. C. Feng, A. H. Ucisik, and C. J. McMahon, Jr.:Met. Trans. A, 1977, vol. 8A, p. 1059.

T. Wada: Unpublished research, Climax Molybdenum Co., Ann Arbor, MI, 1972.

B. J. Schulz: Ph.D. Thesis, Univ. of Pennsylvania, Phila., PA, 1973.

J. Murza and C. J. McMahon, Jr.: Unpublished research, Univ. of Pennsylvania, Phila., PA, 1979.

M. Guttmann:Surf. Sci., 1975, vol. 53, p. 213.

J. Yu: Ph.D. Thesis, University of Pennsylvania, Phila., PA, 1979.

H. Kaneko, T. Nishizawa, T. Tamaki, and A. Tanifuji:J. Jpn Inst. Met., 1965, vol. 29, p. 166.

H. Ohtani, H. C. Feng, and C. J. McMahon, Jr.:Met. Trans., 1974, vol. 5, p. 516.

W. R. Graham and A. C. Yen:Met. Trans. A, 1978, vol. 9A, p. 1461.

R. DiDio and W. R. Graham: Unpublished research, Univ. of Penn., Phila., PA, 1979.

M. Guttmann:Met. Sci., 1976, vol. 10, p. 337.

M. Hillert:Phase Transformations, p. 181, ASM, Metals Park, OH, 1970.

M. Guttmann and D. McLean:Interfacial Segregation, p. 261, ASM, Metals Park, OH, 1978.

H. Ohtani, H. C. Feng, and C. J. McMahon, Jr.:Met. Trans. A, 1976, vol. 7A, p. 1123.

Ph. Dumoulin, M. Foucault, M. Palmier, M. Wayman, M. Biscondi, and M. Guttmann:Mem. Sci. Rev. Met., 1979, vol. 76, p. 187.

R. Viswanathan:Int. Symposium on Optimization of Processing, Properties and Service Performance Through Microstructural Control (MICON), Westinghouse R & D Center Rept. 78-102-GRABO-P1, Houston, April, 1978.

R. Viswanathan and A. Joshi:Met. Trans. A, 1975, vol. 6A, p. 2289.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Yu, J., McMahon, C.J. The effects of composition and carbide precipitation on temper embrittlement of 2.25 Cr-1 Mo steel: Part I. Effects of P and Sn. Metall Trans A 11, 277–289 (1980). https://doi.org/10.1007/BF02660632

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02660632