Abstract

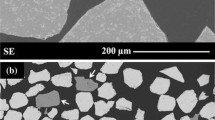

The reduction behavior of a natural chromite from the Bushveld Complex of South Africa was studied at 1300 °C to 1500 °C. Reduction was by graphite in the presence of silica. Thermo-gravimetric analysis, X-ray diffraction (XRD) analysis, energy-dispersive X-ray analysis (EDAX), and metallographic analysis were the experimental techniques used. Silica affected the reduction at and above 1400 °C. A two-stage reduction mechanism was established. The first stage, up to a reduction level of about 40 pct, is primarily confined to iron metallization, and zoning is observed in partially reduced chromites. In this stage, silica does not interfere with the reduction, which proceeds by an outward diffusion of Fe2+ ions and an inward diffusion of Mg2+ and Cr2+ ions. The second stage is primarily confined to chromium metallization, and formation of a silicate slag alters the reduction mechanism. The slag phase agglomerates and even embeds partially reduced chromite particles. An ion-exchange reaction between the re-ducible cations (Cr3+ and Fe2+) in the spinel and the dissolved cations (Al3+ and Mg2+) in the slag allows further reduction. Once the reducible cations are dissolved in the slag phase, they are reduced to the metallic state at sites where there is contact with the reductant.

Similar content being viewed by others

References

Krupp Patent: Process for the Production of Ferrochromium, Application for S.A. Patent 8, 410, 101, Tried Krupp GmbH, 1984.

O. Soykan. R.H. Eric, and R.P. King:Metall. Trans. B, 1991, vol. 22B, pp. 53–63.

O. Soykan, R.H. Eric, and R.P. King:Metall. Trans. B, 1991, vol. 22B, pp. 801–10.

H.G. Katayama, M. Tokuda, and M. Ohtani:Trans. Iron Steel lnst. Jpn., 1982, vol, 22 (3), p. B77.

N.F. Dawson: Ph.D. Thesis, University of Natal, Durban, Republic of South Africa, 1989.

N.L. Woollacott: Report No. 1950, National Institute for Metallurgy. Randburg, Republic of South Africa, 1978.

H.T.T. Tsai: Ph.D. Thesis, The Pennsylvania State University, State College, PA. 1981.

M. Akyuzlu and R.H. Eric:J. S. Afr. Inst. Min. Metall., 1992, vol. 92 (4). pp. 101–10.

A. Novakova. C. Kleir, and J.S. Jim: inReactivity of Solids, G.M. Schwab, ed., Elsevier, New York, NY, 1965, pp. 269–76.

O. Katsutoshi and S. Awazu:J. Phys. Chem. Solids, 1968, vol. 29, pp. 1269–73.

A. Muan: inMintek 50, Proc. Int. Conf. Minerals Science and Technology, vol. 2, L.F. Haughton, ed., Council for Mineral Technology, Randburg, Republic of South Africa, 1985, pp. 897–904.

K. Morita and A. Inoue:Tetsu-to-Hagané, 1988, vol. 74, pp. 999–1005.

K. Morita and N. Sano:Tetsu-to-Hagané, 1988, vol. 74, pp. 133–35.

I. Barin. O. Knacke, and O. Kubaschewski:Thermochemical Properties of Inorganic Substances, Springer-Verlag, Berlin, 1977.

J.D. Tretjakow and H. Schmalzried:Ber. Bunsen-Ges. Phys. Chem., 1966, vol. 69 (5), pp. 396–402.

N. Toker and L.S. Darken:Geochim. Cosmochim. Acta, 1975, vol. 39. pp. 847–52.

H. Schmalzried:Solid State Reaction, Academic Press, New York, NY, 1974.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Weber, P., Eric, R.H. The reduction mechanism of chromite in the presence of a silica flux. Metall Trans B 24, 987–995 (1993). https://doi.org/10.1007/BF02660990

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02660990