Abstract

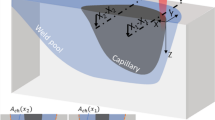

The size and temperature of the “keyhole” and melt pool on the top surface of a metal plate being welded with a keyhole have been calculated, based on the power loss resulting from evaporation of an element in the chemistry of the plate and a minimum power density required to produce a keyhole. The evaporative power loss is set equal to the Gaussian power density which is used to represent the laser beam. The result is a temperature distribution across the keyhole. The results indicate that peak powers below the minimum peak power density yield temperatures that are indicative of melting only; peak powers equal to a minimum power density yield temperatures that reach the evaporation temperature of the element; and peak powers greater than the minimum power density yield temperatures greater than the evaporation temperature of the element. The results will be compared to some visual observations of the laser melt pool.

Similar content being viewed by others

References

The Physics of Welding, 2nd ed., J.F. Lancaster, ed., Pergamon Press, New York, NY, 1986.

P.E. Denney and E.A. Metzbower:Proc ICALEO ’91, San Jose, CA, Nov. 1991.

Smithells Metal Reference Book, 6th ed., Butterworth’s, London, pp. 14-6–14-8.

R. Hultgren, P.D. Desai, D.T. Hawkins, M. Gleisser, and K.K. Kelley:Selected Properties of Binary Alloys, ASM INTERNATIONAL, Metals Park, OH, 1973.

Gerd Herziger:The Industrial Laser Annual Handbook, 1986 ed., D. Belforte and M. Levitt, eds., Pennwell Books, Tulsa, OK, 1986, pp. 108–15.

E. Beyer, K. Behler, K. Hoffmann, and J. Berkmanns:Usertechnik, 1991, vol. 133, pp. 82–86.

Welding Handbook, 8th ed., vol. 2,Welding Processes, American Welding Society, Miami, FL, 1991, p. 727.

J.W. Elmer, W.H. Giedt, and T.W. Eagar:Weld. J., 1990, vol. 69, pp. 167s-176s.

A. Block-Bolten and T.W. Eagar:Trends in Welding Research in the United States, S.A. David, ed., ASM INTERNATIONAL, Metals Park, OH, 1982, pp. 53–73.

A. Block-Bolten and T.W. Eagar:Metall. Trans. B., 1984, vol. 15B, pp. 461–69.

Scientific Foundations of Vacuum Technique, 2nd ed., S. Dushman and J.M. Laferty, eds., John Wiley, New York, NY, 1962, pp. 691–737.

D.A. Schauer, W.H. Giedt, and S.M. Shintaky:Weld. J., 1978, vol. 57, pp. 127s-133s.

D.T. Swift-Hook and A.E.F. Gick:Weld. J., 1973, vol. 52, pp. 492s-499s.

E.A. Metzbower:J. Laser App., 1989, vol. 1, pp. 9–15.

Y. Arata, M. Tomie, N. Abe, and Xiang-Yu Yao:Trans JWRI, 1987, vol. 16, pp. 13–16.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Metzbower, E.A. Keyhole formation. Metall Trans B 24, 875–880 (1993). https://doi.org/10.1007/BF02663148

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02663148