Abstract

By modifying a two-phase fluidized-bed model, two mathematical models which describe the behavior of gas and solid movement and reactions in a fluidized bed as well as interpret the experimental results for the selective chlorination of iron were formulated. One model is based on treating the bubble and emulsion phases as separate continuum phases with mass exchange between them, resulting in differential governing equations. The other is based on the compartmentalization of the fluidized bed into a network of perfectly mixed reactors. Predictions from these models produced satisfactory agreement compared with experimental results. The effects of important variables affecting the bed performance—superficial gas velocity, exchange rate between the phases, and reaction rate constant—were tested.

Similar content being viewed by others

Abbreviations

- a :

-

specific surface (particle surface area/volume of bed, m−1) = 6(1 - εfϕ sdp

- Ao :

-

cross-sectional area of bed (m2)

- A w :

-

wall area of the containing vessel (m{sr2})

- C g,j :

-

gas concentration in phasej in the bed (mol·m−3)

- Cpg,in :

-

mean heat capacity of inlet gases (J kg−1 K−1)

- Cpg,out :

-

mean heat capacity of outlet gases (J kg−1 K−1)

- C ps :

-

heat capacity of unreacted solid at any time (J kg−1K⟷1

- d b :

-

bubble diameter as a function of bed height (m)[22] =d bm−{dbm−dbo)} exp [-(0.3h/ D o)], whered bm = 1.635[Ao(uo − umf)]0.4andd bo= 0.376(u o−u mf)2

- dp :

-

particle diameter (m)

- D o :

-

bed diameter (m)

- D 1m :

-

pseudobinary diffusivity for species 1 in a multicomponent gas mixture[241] = (1 −X 1)/[Σ nj=2 (Xj/D1j)];D 12= 18.583[T3(1/M1 − 1/M1)]0.5/pσ 212 Σ12 m2 s−1), where σ is a parameter in the Lennard-Jones potential function, and Σ is a slowly varying function of kT/ε

- f i,j :

-

volumetric fraction ofi in phasej (Figure 2); since the cloud becomes thinner with increasing bubble velocity, the cloud phase is neglected in the flow rate used

- g :

-

standard acceleration of gravity (m.s−2)

- Gin :

-

mass rate of inlet gases(=u oρgkg m−2 s−1)

- Gout :

-

mass rate of outlet gases which can be calculated from the conversion and stoichiometric equation (kg m−2s−1)

- h :

-

vertical distance from the bottom of the fluidized bed (m)

- h c :

-

height of a compartment (m)

- h p :

-

overall heat transfer coefficient (J s−1 m−2 K−1);[5]h p,app=(k g/dp)[1/(1 − εf)] [γNut ∗ (Σ sdp 26kg)Hbe], where Nut ∗= 2 + 0.6 Pr1/3 Re1/2 andH be=4.5(umfρgCpg/ db) + 55[(kgρgCpg)0.5/db 1.25(J m−3s−1K−1)

- h w :

-

heat transfer coefficient between the bed and wall;h w = (kg/dp) {1 + exp[-0.44(H f/dt) (Cpg/Cps)]} (1 − εf) (Cpsρs/Cpgρg) ψ (J m−2 s−1K−1), where ψ is a dimensionless quantity obtained from the figure of the correlation for heat transfer at container walls[26]

- H f :

-

fluidized bed height (m)

- ΔH r :

-

heat of reaction (J kg−1)

- k :

-

thermal conductivity = 8.322 × 10−5 (⇏T/M/σ 2Σk)(Jm−1s−1K−1) andk mix=

- Kbe :

-

interchange coefficient for gas between bubble and emulsion phases based on bubble volume (s−1);[5] ⇏/Kbe = 1/Kbc + 1/Kce, whereK bc= 4.5(umf/db) + 5.85(D0.5g0.25/ d 1.25b ) and kce =6.78(εmfDub/d 3b 0.5

- Ks :

-

interchange coefficient for solid between bubble and emulsion based on bubble volume (s−1);[4] [3(1 − εmf)/(l − δε mf](u mf/db) (1 + α)δ M molecular weight (g.mol−1)

- p :

-

pressure (kPa) Pr Prandtl number (−)

- r i,j :

-

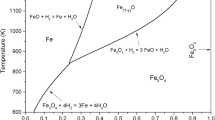

the volumetric reaction rate ofi in phasej based on the following stoichiometric equation: Fe2O3 + 3CO + 3C12 = 2FeCl3 + 3CO2

- r s :

-

volumetric reaction rate(dX/dt, s−1) R the universal gas constant Re Reynolds number (−)

- t :

-

time (s)

- T :

-

temperature (K)

- T g,in :

-

inlet gas temperature (K) Tg,out exit gas temperature (K)

- T ref :

-

reference temperature (K)

- u b :

-

bubble rising velocity (m.s−1) =u o− umf + 2.226

- d) b 0.5ue :

-

gas velocity in emulsion (m.s−1) = (umf/εmf) − [αu o/(1 − δ − α δ) − αumf]

- u mf :

-

minimum fluidization velocity (m.s−1) given by[5] umf =(μ/d) pPg[33.72 + 0.0408 {dρg(ρ) s − ρg)g/μ2)]0.5 −} 33.7

- u o :

-

superficial linear gas velocity (m.s−1)

- u s :

-

velocity of solid in the emulsion (m−1) =αδu b(1 − δ− αδS)

- W o :

-

weight of iron oxide solid (kg)

- W p :

-

weight of unreacted solid at any time (kg)

- x :

-

mole fraction (−)

- X s,j :

-

solid conversion in phasej (−)

- y s,j :

-

1 − xs,j

- α :

-

volumetric ratio of wake to bubble (−)

- γb :

-

ratio of the volume of solids dispersed in bubbles to the volume of bubbles in the bed (−) ° volume fraction of bubbles in the bed (−) =(u o − umf)/ub

- ε mf :

-

voidage at the minimum fluidization (−)

- η h :

-

effectiveness factor for heat transfer (−) λ pore-blocking constant (−)

- μ :

-

viscosity = 2.6693 × 10−4 √MT/σ2Σμ (kg m−1s−1) and μmix = Σ ni=1

- ρ :

-

density (kg.m−3)

- π ij :

-

(1/√8) [1 +(M i/Mj)]− 0.5[1 + (μi/μj)0.5 (Mj/Mi)+0.25]2 ϕs sphericity (−) Subscripts

- b :

-

bubble phase

- e :

-

emulsion phase

- g :

-

gas phases

- mf :

-

minimum fluidization

- s :

-

solid

References

R. Powell:Titanium Oxide and Titanium Tetrachloride, Noyes Development Co., Park Ridge, NJ, 1968, pp. 1–6.

R.D. Toomey and H.F. Johnstone:Chem. Eng. Prog., 1952, vol. 48, pp. 220–26.

J.F. Davidson and D. Harrison:Fluidized Particles, Cambridge University Press, Cambridge, U.K., 1963, pp. 302-51.

B.A. Partridge and P.N. Rowe:Trans. Inst. Chem. Eng., 1966, vol. 44, pp. 335–48.

D. Kunii and O. Levenspiel:Fluidization Engineering, John Wiley & Sons, New York, NY, 1969, pp. 66–73, 178-85 and 219-21.

K. Kato and C.Y. Wen:Chem. Eng. Sci., 1969, vol. 24, pp. 1351–69.

T. Chiba and H. Kobayashi:Proc. Int. Conf. on Fluidization and its Applications, 1973, pp. 468-80.

W.P.M. Van Swaaij and F.J. Zuiderweg:Chem. React. Eng., Proc. Eur. Symp. 5th, Pergamon Press, Oxford, U.K., 1972, vol. B9, pp. 25–36.

J. Werther:Ger. Chem. Eng., 1978, vol. 1, pp. 243–51.

P.F. Wace and S.J. Barnett:Trans. Inst. Chem. Eng., 1956, vol. 43, pp. 157–75.

P.N. Rowe and B.A. Partridge:Trans. Inst. Chem. Eng., 1965, vol.43, pp. 271–86.

I.N. Woollard and O.E. Potter:AlChE J., 1968, vol. 14 (3), pp. 388–91.

K. Yoshida and D. Kunii:J. Chem. Eng. Jpn., 1968, vol. 1 (1), pp. 11–16.

S.P. Babu, S. Leipziger, B.S. Lee and S.A. Weil:AIChE Symp. Ser., 1974, vol. 69 (128), pp. 49–57.

W. Bortz:Chem. Ing. Technik., 1952, vol. 24, pp. 60–81.

J. Van Deemter:Proc. Int. Symp. on Fluidization, Netherlands University Press, Amsterdam, 1967.

L.K. Doraiswamy, H.C. Bijawat, and M.V. Kunte:Chem. Eng. Prog., 1959, vol. 55 (10), pp. 80–88.

A.S. Athavale and V.A. Altekar:Ind. Eng. Chem. Process Des. Dev., 1971, vol. 10 (4), pp. 523–30.

A.J. Morris and R.F. Jensen:Metall. Trans. B, 1976, vol. 7B, pp. 89–93.

C.M. Lakeshmanan, H.E. Hoelescher, and B. Chennakesavan:Chem. Eng. Sci., 1968, vol. 20, pp. 1107–13.

A. Fuwa, E. Kimura, and S. Fukushima:Metall. Trans. B, 1978, vol. 9B, pp. 643–52.

S. Mori and C.Y. Wen:AIChE J., 1975, vol. 21, pp. 109–15.

C.R. Wilke:J. Chem. Phys., 1950, vol. 18, pp. 517–19.

D.F. Fairbanks and C.R. Wilke:Ind. Eng. Chem., 1950, vol. 4 (3), pp. 471–75.

K.I. Rhee and H.Y. Sohn:Metall. Trans. B, 1990, vol. 21B, pp. 321–30.

L. Wender and G.T. Cooper:AIChE J., 1958, vol. 4, pp. 15–23.

.J. More, B.S. Garbow and K.E. Hillstrom: Report ANL-80-74, Argonne National Laboratory, Argonne, IL.

J.R. Grace:AIChE Symp. Ser., 1974, vol. 70 (141), pp. 21–26.

P.N. Rowe:Chem. Reaction Eng., ACS Symp. Ser., American Chemical Society, Washington, DC, 1978, no. 65, pp. 436–46.

C. Chavarice and J.R. Grace:Ind. Eng. Chem. Fundam., 1975, vol. 14(2), pp. 75–91.

C.C. Fryer and O.E. Potter:AIChE J., 1975, vol. 22, pp. 38–47.

O.E. Potter:Catal. Rev.-Sci. Eng., 1978, vol. 17 (2), pp. 155–202.

T. Chiba and H. Kobayashi:Chem. Eng. Sci., 1972, vol. 27, pp. 1375–78.

.A.H. Drinkenburg and K. Rieteura:Chem. Eng. Sci., 1972, pp. 1765-74.

Author information

Authors and Affiliations

Additional information

Formerly Graduate Student at the Department of Metallurgical Engineering, University of Utah

Rights and permissions

About this article

Cite this article

Rhee, K.I., Sohn, H.Y. The selective chlorination of iron from llmenite ore by CO-Cl2 mixtures: Part II. mathematical modeling of the fluidized-bed process. Metall Trans B 21, 331–340 (1990). https://doi.org/10.1007/BF02664201

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02664201