Abstract

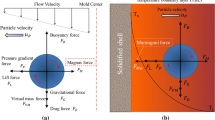

A finite element model has been developed and applied to compute the fluid flow distribution inside the shell in the mold region of a continuous, steel slab-casting machine. The model was produced with the commercial program FIDAP, which allows this nonlinear, highly turbulent problem to be simulated using the K- ε turbulence model. It consists of separate two-dimensional (2-D) models of the nozzle and a section through the mold, facing the broad face. The predicted flow patterns and velocity fields show reasonable agreement with experimental observations and measurements conducted using a transparent plastic water model. The effects of nozzle angle, casting speed, mold width, and turbulence simulation parameters on the flow pattern have been investigated. The overall flow field is relatively insensitive to process parameters.

Similar content being viewed by others

References

H. Nakata, M. Ozawa, K. Kinoshita, Y. Habu, and T. Emi:Trans. Iron Steel Inst. Jpn., 1984, vol. 24 (11), pp. 957–65.

A. Ferretti, M. Podrini, and G. Si Schino:Steelmaking Proc, Iron and Steel Society, 1985, vol. 68, pp. 49–57.

T. Robertson, P. Moore, and J.F. Hawkins:Ironmaking and Steelmaking, 1986, vol. 13 (4), pp. 195–203.

N.A. McPherson:Steelmaking Proc, Iron and Steel Society, 1985, vol. 68, pp. 13–25.

R. Sobolewski and D.J. Hurtuk:2nd Process Technology Conf. Proc, 1982, vol. 2, pp. 160–65.

R.I.L. Guthrie: inMathematical Modelling of Materials Processing Operations, TMS Conf. Proc., Palm Springs, CA, Nov. 29, 1987, J. Szekely, L.B. Hales, H. Henein, N. Jarrett, K. Rajamani, and I. Samarasekera, eds., pp. 447–82.

Y. Sahai: inMathematical Modelling of Materials Processing Operations, TMS Conf. Proc., Palm Springs, CA, Nov. 29, 1987, J. Szekely, L.B. Hales, H. Henein, N. Jarrett, K. Rajamani, and I. Samarasekera, eds., pp. 431–45.

O.J. Ilegbusi and J. Szekely: inMathematical Modelling of Materials Processing Operations, TMS Conf. Proc., Palm Springs, CA, Nov. 29, 1987, J. Szekely, L.B. Hales, H. Henein, N. Jarrett, K. Rajamani, and I. Samarasekera, eds., pp: 409–29.

F.G. Wilson, M.J. Heeson, A. Nicholson, and A.W.D. Hills:Ironmaking and Steelmaking, 1987, vol. 14 (6), pp. 296–309.

M. Yao, M. Ichimiya, K. Syozo, K. Suzuki, K. Sugiyama, and R. Mesaki:Steelmaking Proc, Iron and Steel Society, 1985, vol. 68, pp. 27–34.

J. Kelly, K.P. Michalek, B.G. Thomas, and J.A. Dantzig:Metall. Trans. A, 1988, vol. 19A, pp. 2589–2601.

W. Rodi:Turbulence Models and Their Application in Hydraulics— A State of the Art Review, University of Karlsruhe, Karlsruhe, West Germany, 1980.

K. Spitzer, M. Dubke, and K. Schwertfeger:Metall. Trans. B, 1986, vol. 17B, p. 119.

M.S. Engelman:FIDAP Theoretical Manual-Revision 4.0, Fluid Dynamics International, Inc., Evanston, IL, 1986.

B.E. Launder and D.B. Spalding:Mathematical Models of Turbulence, Academic Press, London, 1972.

F.M. Najjar and B.G. Thomas:Third FIDAP Users Conf., Fluid Dynamics International, Inc., Evanston, IL, Sept. 25, 1989.

L. Prandtl and O. Tietjens:Applied Hydro- and Aeromechanics, McGraw-Hill, New York, NY, 1934.

R.E. Johnstone and M.W. Thring:Pilot Plants, Models and Scale-Up Methods in Chemical Engineering, McGraw-Hill, New York, NY, 1957, p. 199.

Author information

Authors and Affiliations

Additional information

Formerly Graduate Student, Department of Mechanical and Industrial Engineering, University of Illinois-Urbana

Rights and permissions

About this article

Cite this article

Thomas, B.G., Mika, L.J. & Najjar, F.M. Simulation of fluid flow inside a continuous slab-casting machine. Metall Trans B 21, 387–400 (1990). https://doi.org/10.1007/BF02664206

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02664206