Abstract

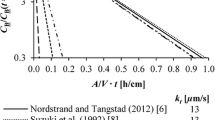

Experiments were carried out on 35 kg melts of doped cathode copper and anode copper in a 3 m3, 150 kW vacuum induction furnace. Rates of removal of bismuth, arsenic, and antimony were measured over temperature and pressure ranges of 1450 to 1610 K and 3 to 30 pascals, respectively. Bismuth removal was found to be rapid: 1 to 18 x 10-5 m/s. Arsenic and antimony removal were quite slow: 0.2 to 3 x 10-5 and 0.1 x 10-5 m/s, respectively, and evaporation controlled rates of refining. It is shown that, at typical concentrations of these elements in copper, monatomic evaporation is the predominant evaporation mechanism. An expression for the melt phase mass transport rate coefficient is developed from Machlin’s model. In this expression, melt diffusion is a function of melt temperature, and melt surface velocity is a function of the square root of melt surface area to volume ratio and the square of melt temperature, i.e.: it = 1.11 x 10-7[(A/V)/]1/4Tr1/2 exp(-2515/T). This coefficient is used to examine rate control in previous small scale studies and in the present and previous pilot scale studies. The gas phase mass transport coefficient is found to be proportional to the overpressure ratio defined as: total initial melt vapor pressure/chamber pressure, and is also found to be dependent on the geometry of the gas space immediately above the melt.

Similar content being viewed by others

References

O. Winkler and R. Bakish:Vacuum Metallurgy, Elsevier, NY, 1974, ch. 1.

R. Ohno:Metall. Trans. B, 1976, vol. 7B, pp. 647–53.

R. Harris and W. G. Davenport:Can. Met. Q., 1979, vol. 18, pp. 303–11.

D. Danovitch: M. Eng. Thesis, McGill University, Montreal, 1982.

E. Ozberk and R. I. L. Guthrie:Proc. 6th International Vacuum Metallurgy Conference, G.K. Blatt and R. Schlatter, eds., San Diego, CA, April 1979, American Vacuum Society, New York, NY, pp. 248–67.

R. G. Ward:JISI, 1963, vol. 201, pp. 11–15.

R. Ohno:Liquid Metals Chemistry and Physics, S.Z. Beer, ed., Marcel Decker, New York, NY, 1972, pp. 38–79.

a,b. F. D. Richardson:Physical Chemistry of Melts in Metallurgy, Academic Press, London, 1974, vols. 1 and 2, a: pp. 483–87; b: pp. 1-14.

M. Olette:Physical Chemistry of Process Metallurgy, Part 2, G. R. St-Pierre, ed., Interscience, New York, NY, 1961, pp. 1065–87.

D. C. Lynch:Metall. Trans. B, 1980, vol. 11B, pp. 623–29.

R. Harris: Ph.D. Thesis, McGill University, Montreal, 1980.

O. Knacke and I. N. Stranski:Progress in Metal Physics, B. Chalmers and R. King, eds., Pergamon, New York, NY, 1956, pp. 181–233.

I. Langmuir:J. Am. Chem. Soc., a: 1914, vol. 36, p. 1708; b: 1915, vol. 37, p. 415; c: 1916, vol. 38, pp. 1145-15.

M. Knudsen:Ann. Physic, Folge 2, a: vol. 31, p. 205; b: vol. 32, p. 890; c: vol. 33, p. 14; d: vol. 34, p. 1910.

E. S. Machlin:Trans. TMS-AIME, 1960, vol. 218, pp. 314–26.

W. G. Davenport, A. V. Bradshaw, and F. D. Richardson:JISI, 1967, vol. 25, p. 1034.

J. Szekely, C. W. Chang, and W. E. Johnson:Metall. Trans. B, 1977, vol. 8B, pp. 514–17.

T. R. A. Davey:J. Metals, 1953, vol. 197, pp. 991–96.

T. R. A. Davey:Vacuum, 1962, vol. 12, pp. 83–95.

T. R. A. Davey:Vacuum, 1964, vol. 14, pp. 227–30.

R. Harris and W. G. Davenport:Metall. Trans. B, a: 1982, vol. 13B, pp. 581–88; b: 1982, vol. 13B, pp. 589-91.

H. Kametani and C. Yamauchi: Trans.JIM, 1972, vol. 13, pp. 13–20.

R. Bryan, D. M. Pollard, and G. M. Willis:Australia-Japan Extractive Metallurgy Symp., Australasian Inst. Min. Met., Parkville, Vic., 1980, pp. 439–48.

R. Ohno:Trans. JIM, 1977, vol. 18, pp. 232–38.

L. Komorova:Hutnicke Listy, 1973, vol. 8, pp. 577–82 (translation: BISI 12425, The Metals Society, London, UK).

F. N. Streltsov, E. G. Trankovski, and O. D. Moldaviskii:Tsvetyne Metally (Non-Ferrous Metals), August 1973, vol. 8, pp. 40–43.

M. Kameda and A. Yasawa:Tohoku Diagaku Senko Seiren Kenkyusho Iho, 1963, vol. 19, pp. 57–68.

H. Salomon de Friedburg and W. G. Davenport:Met. Soc. CIM, Ann. Vol., 1977, pp. 225–31.

V. V. Golovko and R. A. Isakova:Trans. Inst. Met. i Obogashch. Akad. Nauk Kaz. SSR, 1965, vol. 13, pp. 32–37.

G. V. Kim and A. N. Kvyatkovskii:Tr. Altaisk Gorno-Met. Nauchn-Issledlnst., Akad. Nauk. Kaz. SSR, 1963, vol. 14, pp. 86–89.

T. Azakami and A. Yasawa:Can. Met. Q., 1976, vol. 15, pp. 111–21.

S. Arac and G. H. Geiger:Metall. Trans. B, 1981, vol. 12B, pp. 569–78.

G. K. Sigworth and J. F. Elliot:Can. Met. Q., 1974, vol. 13, pp. 455–61.

O. Kubashewski and C. B. Alcock:Metallurgical Thermochemistry, 5th edition, Pergamon, Oxford, 1979, pp. 358–77.

R. Hultgren, P. D. Desai, D. T. Hawkins, M. Gleiser, and K. K. Kelly:Selected Values of the Thermodynamic Properties of Binary Alloys, ASM, Metals Park, OH, 1973, pp. 247–52.

R. Harris, R. McClincy, and E. F. Rebling: Paper Selection No. A83-19, 1983, TMS-AIME, Warrendale, PA, pp. 1–7.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Harris, R. Vacuum refining copper melts to remove bismuth, arsenic, and antimony. Metall Trans B 15, 251–257 (1984). https://doi.org/10.1007/BF02667328

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02667328