Abstract

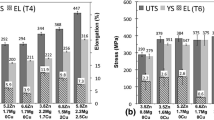

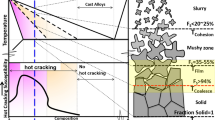

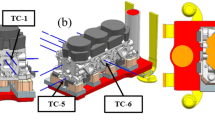

A metallographic study of the porosity and fracture behavior in unidirectionally solidified end chill castings of 319.2 aluminum alloy (Al-6.2 pct Si-3.8 pct Cu-0.5 pct Fe-0.14 pct Mn-0.06 pct Mg-0.073 pct Ti) was carried out using optical microscopy and scanning electron microscopy (SEM) to determine their relationship with the tensile properties. The parameters varied in the production of these castings were the hydrogen (∼0.1 and ∼0.37 mL/100 g Al), modifier (0 and 300 ppm Sr), and grain refiner (0 and 0.02 wt pct Ti) concentrations, as well as the solidification time, which increased with increasing distance from the end chill bottom of the casting, giving dendrite arm spacings (DASs) ranging from ∼15 to ∼95 /im. Image analysis and energy dispersive X-ray (EDX) analysis were employed for quantification of porosity/microstructural constituents and fracture surface analysis (phase identification), respectively. The results showed that the local solidification time(viz. DAS) significantly influences the ductility at low hydrogen levels; at higher levels, however, hydro-gen has a more pronounced effect (porosity related) on the drop in ductility. Porosity is mainly observed in the form of elongated pores along the grain boundaries, with Sr increasing the porosity volume percent and grain refining increasing the probability for pore branching. The beneficial effect of Sr modification, however, improves the alloy ductility. Fracture of the Si, β-Al5FeSi, α- Al15(Fe,Mn)3Si2, and Al2Cu phases takes place within the phase particles rather than at the particle/Al matrix interface. Sensitivity of tensile properties to DAS allows for the use of the latter as an indicator of the expected properties of the alloy.

Similar content being viewed by others

References

A.M. Samuel and F.H. Samuel:J. Mater. Sci., 1995, vol. 30, in press.

K.E. Tynelius: Ph.D. Thesis, Drexel University, Philadelphia, PA, 1992.

J. Charbonnier, J. Maurice, and R. Portallier:AFS Int. Cast Met. J., 1979, Sept., pp. 39–44.

L. Backerud and G. Sigworth:Am. Foundrymen’s Soc. Trans., 1989, vol. 97, pp. 459–64.

M.H. Mulazimoglu, N. Tenekedjiev, B.M. Closset, and J.E. Gruzleski:Cast Met., 1993, vol. 6, pp. 16–28.

L.A. Narayanan, F.H. Samuel, and J.E. Gruzleski:Metall. Mater. Trans. A, 1994, vol. 25A, pp. 1761–73.

G. Gustafsson, T. Thorvaldsson, and G.L. Dunlop:Metall. Trans. A, 1986, vol. 17A, pp. 45–52.

R.E. Spear and G.R. Gardner:Am. Foundrymen’s Soc. Trans., 1963, vol. 71, pp. 209–15.

S.F. Frederick and W.A. Bailey:Trans. AIME, 1968, vol. 242, pp. 2063–67.

J.F. Major, A. Makinde, P.D. Lee, B. Chamberlain, T. Scappaticci, and D. Richman:Int. Congr. Expos, on Vehicle Suspension System Advancements, Detroit, MI, Feb. 28-Mar. 3, 1994, pp. 117-28.

K. Radhakrishna, S. Seshan, and M.R. Seshadri:Trans. Ind. Inst. Met., 1981, vol. 34, pp. 169–71.

E.N. Pan, C.S. Lin, and C.R. Loper, Jr.:Am. Foundrymen’s Soc. Trans., 1990, vol. 98, pp. 735–46.

S. Shivkumar, L. Wang, and R. Lavigne:Light Metals 1993, S.K. Das, ed., TMS, Warrendale, PA, 1993, pp. 829–38.

E.N. Pan, H.S. Chiou, and G.J. Liao:Am. Foundrymen’s Soc. Trans., 1991, vol. 99, pp. 605–21.

H. Beumler, A. Hammerstad, R. Weiting, and R. DasGupta:Am. Foundrymen’s Soc. Trans., 1988, vol. 96, pp. 1–12.

R.C. Voigt and D.R. Bye:Am. Foundrymen’s Soc. Trans., 1991, vol. 99, pp. 33–50.

R. DasGupta, C.G. Brown, and S. Marek:Am. Foundrymen’s Soc. Trans., 1988, vol. 96, pp. 297–310.

A. Gangulee and J. Gurland:Trans. AIME, 1990, vol. 239, pp. 605- 21.

P.N. Crepeau, S.D. Antolovich, and J.A. Worden:Am. Foundrymen’s Soc. Trans., 1990, vol. 98, pp. 813–22.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Samuel, A.M., Samuel, F.H. A metallographic study of porosity and fracture behavior in relation to the tensile properties in 319.2 end chill castings. Metall Mater Trans A 26, 2359–2372 (1995). https://doi.org/10.1007/BF02671250

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02671250