Abstract

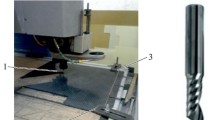

The current focus of manufacturing research on fibre-reinforced plastics (FRP) is composed of the search for efficient processing techniques capable of providing high quality machined surfaces. Very limited work has been performed to identify the influence of manufacturing processes like edge-trimming and drilling on material performance. Recent reports suggest that process-induced damage may affect the mechanical behaviour of FRP materials. Therefore an experimental study of orthogonal cutting was conducted on the edge trimming of unidirectional and multi-directional graphite/epoxy composites with polycrystalline diamond tools. The effects of tool geometry and operating conditions were evaluated from an analysis of chip formation, cutting force, and machined surface topography. All aspects of material removal were found to be primarily dependent on fibre orientation. Discontinuous chip formation was noted throughout this study, regardless of machining parameters. Three distinct mechanisms in the edge trimming of fibre-reinforced composite material including a combination of cutting, shearing, and fracture along the fibre/matrix interface were observed. An investigation conducted on the compression, flexural and impact strength of graphite/epoxy composites machined by both traditional and non-traditional techniques, confirms that manufacturing characteristics may not only affect bulk properties but also influence the initiation and propagation of failure.

Similar content being viewed by others

References

Abrate S, Walton D A 1992a Machining of composite materials. Part I: Traditional methods.Compos. Manuf. 3: 75–83

Abrate S, Walton D 1992b Machining of composite materials. Part II: Non-traditional methods.Compos. Manuf. 3: 85–94

Arola D, Ramulu M 1994 Machining induced surface texture effects on the flexural properties of a graphite/epoxy laminate.Composites 25: 822–833

Arola D, Ramulu M 1995 Manufacturing effects on the impact properties of graphite/epoxy composite.Proceedings of the 10th Annual Technology Conference of American Society of Composites (in press)

ASTM 1986Standard test methods for the flexural properties of unreinforced and reinforced plastics and electrical insulating materials. ASTM D790M

Colligan K 1993Machined edge effects on the compression strength of graphite/epoxy. MS thesis, University of Washington, Seattle

Colligan K, Ramulu M 1992 The effect of edge trimming on composite surface plies.Manuf. Rev. 5: 274–283

Ghasemi Nejjad M N, Chou T-W 1990 Compression behaviour of woven carbon fibre-reinforced epoxy composite with molded in and drilled holes.Composites 21: 33–40

Griswold N C, Massarweh W A, Hough C L 1989 Morphological structures in analysis and inspection of hole quality in fiber composites.J. Testing Eval. 17: 281–286

Ho-Cheng H, Dharan C K H 1990 Delamination during drilling in composite laminates.J. Eng. Ind. 112: 39–47

Howarth S G, Strong A B 1990 Edge effects with waterjet and laser beam cutting of advanced composite materials. In35th International SAMPE Symposium, pp 1685–1697

Inoue H, Ido M 1986 Study on the cutting mechanism of GFRP. InProceedings of Int. Symp. on Composite Materials and Structures, Beijing, pp 1110–1115

Jamil S J, Chambers A R 1991 Evaluation of surface quality of drilled holes in composite materials after high speed drilling. InAdvance machining for quality and productivity (incorporating the 2nd International Conference on the Behavior of Materials in Machining, 1991), pp 70–76

Kaneeda T 1991 CFRP Cutting mechanism.Trans. North Am. Manuf. Res. Inst. SME 19: 216–221

Kinkaid R 1988 Quality holes in composites with PCD cutting tools.Cutting Tool Eng. 40: 50–52

König W, Wulf C, Graf P, Willersceid H 1985 Machining of fiber reinforced plastics.Ann. CIRP 34: 537–547

Koplev A 1980 Cutting of CFRP with single edge tools. InProc. of 3rd Int. Conf. on Composite Materials, Paris, pp 1597–1605

Koplev A, Lystrup A, Vorm T 1983 The cutting process, chips and cutting forces in machining CFRP.Composites 14: 371–376

Krisnamurthy R, Santhanakrishnan G, Malhotra S K 1992 Machining of polymeric composites. InMachining of Composites (Columbus, OH: ASM) pp 139–148

Lin H J, Lee Y J 1992 Strength of composite laminates with continuous fiber around a circular hole.Compos. Struct. 21: 155–162

McCarty J E 1993 Design and cost viability of composites in commercial aircraft.Composites 24: 361–365

Mehta M, Reinhart T J, Soni A H 1992 Effect of fastener hole drilling anomalies on structural integrity of PMR-15/Gr composite laminates. InMachining of composites (Columbus, OH: ASM) pp 113–126

Miller R K 1991 Waterjet cutting: Technology and industrial applications (Liburn, GA: Fairmont)

Mortimer J 1987 New technology brings quality to manufacture.Ind. Robot 14: 103–104

Park J 1991Study on the effect of PCD tool geometry on the machining of graphite/epoxy composite materials. MS thesis, University of Washington, Seattle

Pengra J J, Wood R E 1980 The influence of hole quality on graphite/epoxy composite laminates. InProceedings of the AIAA/ASME/ASCE/AHS 21st Structures, Structural Dynamics and Materials Conference AIAA Paper 80-0777, pp 687–693

Philips J L, Parker R T 1987 Fastener hole considerations. InEngineered materials handbook, Composites (Columbus, OH: ASM) pp 712–715

Pipes R B, Pagano N J 1970 Interlaminar stresses in composite laminates under uniform axial extension.J. Compos. Mater. October: 538–548

Ramulu M, Arola D 1993 Water jet and abrasive water jet cutting of unidirectional graphite/epoxy composite.Composites 24: 299–308

Ramulu M, Arola D 1994 The influence of abrasive waterjet cutting conditions on the surface quality of graphite/epoxy laminates.Int. J. Mach. Tools Manuf. 34: 295–314

Ramulu M, Wern C W, Garbini J L 1993 Effect of fiber direction on surface roughness measurements of machined graphite/epoxy composite.Compos. Manuf. 4: 39–51

Riggs J P 1984 Emerging non-metallic structural materials used for airframes and other demanding applications.Mater. Soc. 8: 351–376

Sadat A B 1988 Machining of graphite/epoxy composite material.SAMPE Q. 19: 1–4

Sakuma K, Seto M 1983 Tool wear in cutting glass-fiber-reinforced plastics.Bull. JSME 26: 1420–1427

Tagliaferri V, Di Illio A, Crivelli Visconti I 1985 Laser cutting of fibre reinforced polyesters.Composites 16: 317–325

Tagliaferri V, Caprino G, Diterlizzi A 1990 Effect of drilling parameters on the finish and mechanical properties of GFRP composites.Int. J. Mach. Tools Manuf. 30: 77–84

Wang D H 1993Machining characteristics of graphite/epoxy composites. Ph D thesis, University of Washington, Seattle

Wang D H, Ramulu M, Wern C W 1992 Orthogonal cutting characteristics of graphite/epoxy composite material.Trans. NAMRI/SME 20: 159–165

Wang D H, Ramulu M, Arola D 1995a Orthogonal cutting mechanisms of graphite/epoxy composite, Part I: Unidirectional laminate.Int. J. Mach. Tools Manuf. 35: 1623–1638

Wang D H, Ramulu M, Arola D 1995b Orthogonal cutting mechanisms of graphite/epoxy composite, Part II: Multi-directional laminate.Int. J. Mach. Tools Manuf. 35: 1639–1648

Wern C W 1991Surface characteristics of machined graphite/epoxy composites. M S thesis, University of Washington, Seattle

Wood R E 1978 Graphite/epoxy composite hole quality investigation. In10th National SAMPE Technical Conference, Materials Synergisms 10: 636–650

You S-S, Chou T-W 1988 Strength of woven-fabric composites with drilled and molded holes. In8th Conference on Composite Materials: Testing and Design, ASTM STP 972, pp 423–437

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ramulu, M. Machining and surface integrity of fibre-reinforced plastic composites. Sadhana 22, 449–472 (1997). https://doi.org/10.1007/BF02744483

Issue Date:

DOI: https://doi.org/10.1007/BF02744483