Abstract

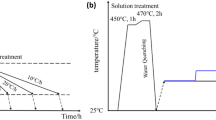

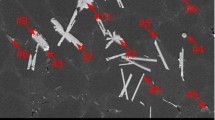

To decrease the accumulation of damage during long-life low-stress cyclic loading, microstructures must accommodate inelastic deformation by homogeneous or “dispersed” slip rather than by localized slip concentrations. In age-hardening aluminum alloys this requirement can be met by introducing a dense and uniform dislocation forest through suitable thermo-mechanical treatments. Such a treatment was developed for Al-Zn-Mg-Cu (7075) alloys, involving a process cycle of solution annealing, partial aging, mechanical working and final aging. The fatigue properties (S-N curves) of commercial and high-purity 7075TMT are compared with conventional 7075-T651 properties; with zero mean stress the alternating stress to cause failure in 107 cycles is more than 25 pct higher for commercial-purity 7075TMT and almost 50 pct higher for high-purity 7075TMT. The results emphasize the importance of microstructural control when high fatigue resistance is required.

Similar content being viewed by others

References

P. J. E. Forsyth:Proc. of the Crack Propagation Symposium, Cranfield, 1961, pp. 76–94, College of Aeronautics, Cranfield, 1962.

P. J. E. Forsyth:Acta Met., 1963, vol. 11, pp. 703–715.

P. J. E. Forsyth:J. Australian Inst Metals, 1963, vol. 8, pp. 52–60.

A. J. McEvily, Jr, J. B. Clark, E. C. Utley, and W. H. Herrnstein, III:Trans. TMS-AIME, 1963, vol. 227, pp. 1093–97.

J. B. Clark and A. J. McEvily:Acta Met, 1964, vol. 12, pp. 1359–72.

A. J. McEvily, Jr, J. B. Clark, and A. P. Bond:Trans. ASM, 1967, vol. 60, pp. 661–71.

T. Broom, J. A. Mazza, and V. N. Whittaker:J. Inst. Metals, 1957–58, vol. 86, pp. 17.

I. J. Polmear and I. F. Bainbridge:Phil. Mag., 1959, vol. 4, pp. 1293–1304.

C. A. Stubbington and P. J. E. Forsyth:Acta Met., 1966, vol. 14, pp. 5–12.

A. Abel and R. K. Ham:Acta Met., 1966, vol. 14, pp. 1495–1503.

J. C. Grosskreutz and G. G. Shaw:Mechanisms of Fatigue in 7075-T6 Aluminum, AFML-TR-66-96, May 1966, AD 486 769.

J. C. Grosskreutz and G. G. Shaw:Critical Mechanisms in the Development of Fatigue Cracks in 2024-T4 Aluminum, AFML-TR-68-137, May 1968, AD 840 403.

J. C. Grosskreutz and G. G. Shaw:Fracture-1969, Proc. Second Intern. Conf. on Fracture, Brighton, April 1969, P. L. Pratt, ed., p. 620, Chapman and Hall, Ltd.

C. Laird and G. Thomas:Intern. J. Fracture Mech., 1967, vol. 3, pp. 81–97.

A. R. Krause and C. Laird:Mater. Sci. Eng., 1967–68, vol. 2, pp. 331–47.

C. Laird and A. R. Krause:Inelastic Behavior of Solids, M. F. Kanninen, W. F. Adler, A. R. Rosenfield, and R. I. Jaffee, eds., pp. 691–715. McGraw-Hill Book Co., New York, 1970.

F. G. Ostermann and W. H. Reimann:ASTM Spec. Tech. Publ. 467, Am. Soc. Testing Mater, 1970, pp. 169–87.

G. Thomas and J. Nutting:J. Inst. Metals, 1957–58, vol. 86, pp. 7–14.

M. O. Speidel:Fundamental Aspects of Stress Corrosion Cracking, pp. 561–79, National Association of Corrosion Engineers, Texas, 1969.

A. J. Jacobs:Fundamental Aspects of Stress Corrosion Cracking, pp. 530–57, National Association of Corrosion Engineers, Texas, 1969.

F. Ostermann and A. W. Brisbane: unpublished research, 1970.

H. A. Holi:J. Inst. Metals., 1969, vol. 97, pp. 200–05.

R. B. Nicholson, G. Thomas and J. Nutting:J. Inst. Metals, 1958–59, vol. 87, pp. 429–38.

G. Thomas and J. Nutting:J. Inst. Metals., 1959–60, vol. 88, pp. 81–90.

G. Thomas:Phil. Mag., 1959, vol. 4, pp. 606–11.

H. A. Holi:J. Inst. Metals, 1964–65, vol. 93, pp. 364–65.

H. A. Holl:Metal Sci. J., 1967, vol. 1, pp. 111–18.

B. J. Lazan and A. A. Blatherwick: WADC-TR-52-307, Pt. I, 1953, AD 7610.

B. J. Lazan and A. A. Blatherwick: WADC-TR-52-307, Pt. II, 1952, AD 8136.

P. Brenner:Aluminum, 1956, vol. 32, pp. 756–68.

J. C. Grosskreutz, G. G. Shaw, and D. K. Benson:The Effect of Inclusion Size and Distribution on Fatigue of 2024-T4 Aluminum, AFML-TR-69-121, 1969, AD 856 763.

F. Ostermann: unpublished research, 1971.

J. H. Mulherin and H. Rosenthal:Met. Trans., 1971, vol. 2, pp. 427–32.

C. E. Feltner and P. Beadmore:ASTM Spec. Tech. Publ. 467, Am. Soc. Testing Mater., 1970, pp. 77–112.

C. E. Feltner unpublished research, cited in Ref. 16.

T. Endo and JoDean Morrow:J. Mater., 1969, vol. 4, pp. 159–75.

Author information

Authors and Affiliations

Additional information

F. OSTERMANN, formerly with Air Force Materials Laboratory, Wright-Patterson Air Force Base, Ohio.

Rights and permissions

About this article

Cite this article

Ostermann, F. Improved fatigue resistance of Al-Zn-Mg-Cu (7075) alloys through thermomechanical processing. Metall Trans 2, 2897–2902 (1971). https://doi.org/10.1007/BF02813269

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02813269