Abstract

The effects of intercritical heat treatment (ICHT) on the microstructure and mechanical properties of C-Mn, 8630 type, and high strength low alloy (HSLA) cast steels have been investigated. A review of the cast steel literature indicates that intercritical heat treatment has been reported to result in improvements in low temperature toughness when used instead of standard quench and temper or normalize and temper heat treatments. However, it is not clear if this reported benefit of intercritical heat treatment can be achieved without corresponding decreases in strength and hardness.

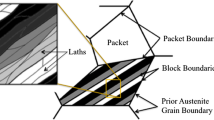

Heat treatment on C-Mn and 8630 type case steels have shown that improvements in low temperature toughness due to intercritical heat treatment are due primarily to the significantly lower yield strength levels that occurred after heat treatment—even when the tempering temperature was adjusted to result in the same final tempered hardness values. Although the duplex ferrite/tempered martensite microstructures resulting from intercritical heat treatment had improved toughness, the ferrite present in the microstructure, in general, caused significant reductions in the yield strength.

Intercritical heat treatment of HSLA cast steels (microalloyed with small V and/or Nb additions) also resulted in dramatic improvements in toughness but without a corresponding large drop in yield strength. Although similar ferrite/tempered martensite microstructures were produced, the addition of microalloys caused the precipitation of vanadium and/or niobium carbonitrides during intercritical heat treatment and upon tempering that strengthened the ferrite grains considerably. Therefore, although intercritical heat treatment is generally of little benefit to the mechanical properties of conventional cast steels, intercritical heat treatment of HSLA cast steels can result in an improved combination of strength and toughness.

Similar content being viewed by others

References

M.A. Meyers and K.K. Chawla,Mechanical Metallurgy Principles and Applications, Prentice-Hall, 1984, p. 525.

Structure and Properties of Dual-Phase Steels, R.A. Kot and J.W. Morris, eds., conference proceedings, The Metallurgical Society, New Orleans, 1979.

Fundamentals of Dual Phase Steels, R.A. Kot and B.L. Bramfitt, eds., conference proceedings, The Metallurgical Society, Chicago, 1981.

Metallurgy of Continuously Annealed Sheet Steels, B.L. Bramfitt and P.L. Mangnon, Jr., eds., conference proceedings, The Metallurgical Society, 1982.

Technology of Continuously Annealed Cold-Rolled Sheet Steels, R. Procthan, ed., conference proceedings, The Metallurgical Society, Detroit, 1984.

Processing, Microstructure and Properties of HSLA Steels, A.J. DeArdo, ed., conference proceedings, The Metallurgical Society, Pittsburgh, 1987.

P.F. Wieser, “A Literature Survey of Intercritical Heat Treatment,” Steel Founders’ Society of America, Special Report No. 19, Rocky River, Ohio, 1982.

J. Leger, P. Maynier, M. Toitot, and P. Bastien, “Etude des Traitements Intercritiques (A1-A3) des Aciers Hypoeutectoides,” Memoires Scientifiques de la Revue de Metallurgie65, No. 5, 1971, p. 313.

M.-T. Leger, P. Detrez, and J.-M. Schissler, “Aciers Moules A Dispersoides Etude de Nuances au Vanadium a Bas Carbone,”Founderie, No. 370, 1977, p. 259.

M.-T. Leger, B. Malapel, G. Romestant, J.-P. Desloire, and J. Terzolo, “Aciers Moules pour Emploi Aux Basses Temperatures de type 10 NM10-M,”Founderie, No. 374, 1978, p. 3.

M.-T. Leger and M. Dunet, “Le Traitment Intercritique des Aciers Moules,”Founderie-Fondeur d’ Arijourd’hui, No. 34, 1984, p. 39.

M.-T. Leger, “Characterization of HSLA Cast Steel 12 MDV6-M Influence of Wall Thickness and Heat Treatment,” Proceedings of the 1st Intl. Steel Foundry Congress, November 11–13, 1985, Chicago, p. 145.

G. Zaino, “Improving Impact Properties of Cast Steel with Ladle Desulphurization and Intercritical Heat Treatment,” Proceedings of the Steel Founders’ Society of America T & O Conference, November 1983, Chicago.

K.A. Davis, I.G. Magny, and G. Zaino, “Intercritical Heat Treatment of Cast Steels,” AFS Transactions91, 1983, p. 325.

M.R. Hough and K. Selby, “Intercritical Heat Treatment—Does It Work?,” Proceedings of the SCRATA Conference, Paper 11, 1984.

D.E. Dutcher, “Production and Properties of Microalloyed Steel Castings,” Proceedings of the Steel Founders’ Society of America T & O Conference, November 14–16, 1987, Chicago.

J. Rassizadehghani and R.C. Voigt, “Intercritical Heat Treatment of C-Mn and 8630 Type Cast Steels,” Research Report No. 101, Steel Founders’ Society of America, Des Plaines, Illinois, July 1987.

J. Rassizadehghani, R. Gattu, and R.C. Voigt, “Initial Investigation of Microalloyed Cast Steel,” Proceedings of the Steel Founders’ Society of America T & O Conference, November 14–16, 1987, Chicago.

R.C. Voigt, J. Rassizadehghani, and R.K. Gattu, “The Development of High Strength Low Alloy (HSLA) Cast Steels,” Proceedings of the Steel Founders’ Society of America T & O Conference, November 20–22, 1988, Chicago.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Voigt, R.C. Analysis of intercritical heat treatment of cast steels. J. Heat Treating 7, 95–105 (1989). https://doi.org/10.1007/BF02833194

Issue Date:

DOI: https://doi.org/10.1007/BF02833194