Abstract

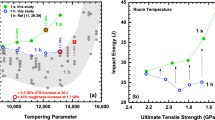

Time-temperature relationships for short-time tempering cycles were determined. The accuracy of conventional tempering parameters, such as the one proposed by Grange and Baughman, for short-time treatments at a fixed temperature (“isothermal” treatments) was established in salt-pot experiments for a variety of carbon and alloy steels fully hardened to martensite. In addition, the concept of an effective tempering parameter for tempering processes consisting of continuous heating and cooling (typical of induction-heating techniques) was developed. Determination of this effective tempering parameter is based on finding an effective time and temperature which allows the continuous cycle to be described in terms of an equivalent isothermal cycle. The applicability of this new technique was verified through laboratory induction tempering trials.

Similar content being viewed by others

References

M. A. Grossman and E. C. Bain:Principles of Heat Treatment, American Society for Metals, Metals Park, OH, 1964.

G. Krauss:Principles of Heat Treatment of Steel, ASM, Metals Park, OH, 1980.

K. -E. Thelning:Steel and Its Heat Treatment, Butterworths, London, 1975.

C. R. Brooks:Heat Treatment of Ferrous Alloys, Hemisphere Publishing Corporation, Washington, 1979.

J. H. Hollomon and L. D. Jaffe:Trans. AIME, 1945, vol. 162, p. 223.

D. K. Bullens:Steel and Its Heat Treatments, Wiley, New York, 1948.

R. A. Grange and R. W. Baughman:Trans. ASM, 1956, vol. 48, p. 165.

J. W. Poynter:Trans. ASM, 1946, vol. 36, p. 165.

D. L. Martin and W. G. VanNote:Trans. ASM, 1946, vol. 36, p. 210.

S. L. Semiatin, D. E. Stutz, and T. G. Byrer:J. Heat Treat., vol. 4, 1985, p. 47–55.

J. L. Burns, T. L. Moore, and R. S. Archer:Trans. ASM, 1938, vol. 26, p. 1.

Z. Jeffries:Trans. ASST, 1927, vol. 12, p. 871.

J. M. Hodge and M. A. Orehoski:Trans. AIME, 1946, vol. 167, p. 627.

C. A. Tudbury:Basics of Induction Heating: Volume 1, John F. Rider, Inc., New Rochelle, New York, 1960.

B. Urband:Ind. Heat., April 1983, vol. 50, no. 4, p. 20.

S. L. Semiatin and D. E. Stutz:Induction Heat Treatment of Steel, ASM, Metals Park, OH, 1985 (in press).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Semiatin, S.L., Stutz, D.E. & Byrer, T.G. Induction tempering of steel: Part I. Development of an effective tempering parameter. J. Heat Treating 4, 39–46 (1985). https://doi.org/10.1007/BF02835488

Issue Date:

DOI: https://doi.org/10.1007/BF02835488