Abstract

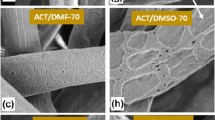

We report a new approach to fabricate electrospun polymer nonwoven mats with porous surface morphology by varying the collector temperature during electrospinning. Polymers such as poly(L-lactide) (PLLA), polystyrene (PS), and poly(vinyl acetate) (PVAc) ere dissolved in volatile solvents, namely methylene chloride (MC) and tetrahydrofuran (THF), and subjected to electrospinning. The temperature of the collector in the electrospinning device was varied by a heating system. The resulting nonwoven mats were characterized by using scanning electron microscopy (SEM), field emission SEM (FESEM), and atomic force microscopy (AFM). We observed that the surface morphology, porous structure, and the properties such as pore size, depth, shape, and distribution of the nonwoven mats were greatly influenced by the collector temperature.

Similar content being viewed by others

References

A. Ziabicki,Fundamentals of Fiber Formation: the Science of Fiber Spinning and Drawing, Wiley, New York, 1976.

Y. J. Ryu, H. Y. Kim, K. H. Lee, H. C. Park, and D. R. Lee,Eur. Polym. J.,39, 1883 (2003).

M. M. Hohman, M. Shin, G. C. Rutledge, and M. P. Brenner,Phys. Fluids,13, 2221 (2001).

P. K. Baumgarten,J. Colloid Interf. Sci.,36, 71 (1971).

D. H. Reneker, A. L. Yarin, H. Fong, and S. Koombhongse,J. Appl. Phys.,87, 4531 (2000).

K. H. Lee, H. Y. Kim, Y. M. La, D. R. Lee, and N. H. Sung,J. Polym. Sci.; Part B: Polym. Phys.,40, 2259 (2002).

M. Bognitzki, H. Hou, M. Ishaque, T. Frese, M. Hellwig, C. Schwarte, A. Schaper, J. H. Wendorff and A. Greiner,Adv. Mater.,12, 637 (2000).

M. Bognitzki, W. Czado, T. Frese, A. Schaper, M. Hellwig, M. Steinhart, A. Greiner, and J. H. Wendorff,Adv. Mater.,13, 70 (2001).

C. L. Casper, J. S. Stephens, N. G. Tassi, D. B. Chase, and J. F. Rabolt,Macromolecules,37, 573 (2004).

S. Megelski, J. S. Stephens, D. B. Chase, and J. F. Rabolt,Macromolecules,35, 8456 (2002).

D. H. Reneker and I. Chun,Nanotechnology,36, 169 (1997).

C. J. Buchko, L. C. Chen, Y. Shen, and D. C. Martin,Polymer,40, 7397 (1999).

L. Huang, R. A. McMillan, R. P. Apkarian, B. Pourdeyhimi, V. P. Conticello, and E. L. Chaikof,Macromolecules,33, 2989 (2000).

L. Huang, K. Nagapudi, R. P. Apkarian, and E. L. Chaikof,J. Biomater. Sci. Polym. Ed.,12, 979 (2001).

J. D. Stitzel, G. L. Bowlin, K. Mansfield, G. E. Wnek, and D. G. Simpson,Int. SAMPE Tech. Conf.,32, 205 (2000).

E. D. Boland, G. E. Wnek, D. G. Simpson, K. J. Pawlowski, and G. L. Bowlin,J. Macromol. Sci. Pure Appl. Chem.,A38, 1231 (2001).

X. Zong, K. Kim, D. Fang, S. Ran, B. S. Hsiao, and B. Chu,Polymer,43, 4403 (2002).

K. Nagapudi, W. T. Brinkman, J. E. Leisen, L. Huang, R. A. McMillan, R. P. Apkarian, V. P. Conticello, and E. L. Chaikof,Macromolecules,35, 1730 (2002).

J. A. Matthews, G. E. Wnek, D. G. Simpson, and G. L. Bowlin,Biomacromolecules,3, 232 (2002).

W. J. Li, C. T. Laurencin, E. J. Caterson, R. S. Tuan, and F. K. Ko,J. Biomed. Mater. Res.,60, 613 (2002).

E. R. Kenawy, J. M. Layman, J. R. Watkins, G. L. Bowlin, J. A. Matthews, S. G. Simpson, and G. E. Wnek,Biomaterials,24, 907 (2003).

B. D. Ratner,Trends Polym. Sci.,2, 402 (1994).

J. Schmidt and A. F. von Recum,Biomaterials,13, 1059 (1992).

A. Curtis and C. Wilkinson,Biomaterials,18, 1 (1997).

E. Richter, G. Fuhr, T. MuÈller, S. Shirley, S. Rogaschewski, K. Reimer, and C. Dell,J. Mater. Sci. Mater. Med.,7, 85 (1996).

W. Liu, Z. Wu, and D. H. Reneker,Polym. Prepr.,41, 1193 (2000).

A. C. Backman and K. A. H. Lindberg,J. Appl. Polym. Sci.,91, 3009 (2004).

H. Matsuyama, M. Teramoto, R. Nakatani, and T. Maki,J. Appl. Polym. Sci.,74, 171 (1999).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, C.H., Jung, Y.H., Kim, H.Y. et al. Effect of collector temperature on the porous structure of electrospun fibers. Macromol. Res. 14, 59–65 (2006). https://doi.org/10.1007/BF03219069

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF03219069