Abstract

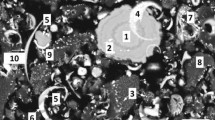

There are numerous viable approaches to the treatment of anode slimes from electrolytic copper refining. Of particular interest in the treatment of slimes are the behavior and recovery of selenium. The understanding of the process chemistry involved in the treatment of anode slimes should be aided considerably by recent work on the formation and characterization of slimes. Most promising is a direct furnace treatment of decopperized and detellurized slimes, in which selenium is volatilized as the dioxide, impurities such as lead are slagged off, and a high-quality doré metal is obtained.

Similar content being viewed by others

References

W.C. Cooper, “A Review of Processes for the Treatment of Copper Refinery Anode Slimes with Particular Reference to Selenium Behaviour and Recovery,” final report on project no. 169/02/87, Energy, Mines and Resources Canada, CANMET, Ottawa, Canada K1A 0G1 (August 1989).

J.E. Hoffmann, “Recovering Selenium and Tellurium from Copper Refinery Slimes,” JOM (July 1989), pp. 33–38.

G. Zárate and F. González, “Process Definition for Anodes Slimes Treatment,” Hydrometallurgy and Electrometallurgy of Copper, ed. W.C. Cooper, G.E. Lagos and G. Ugarte (Santiago: University of Chile, 1988), pp. 499–524.

J.P. Kemper, “Precious Metals,” Eng. & Min. J. (September 1981), pp. 74–75.

R. Bresee, D. Vleeschhouwer and J. Thiriar, “The Recovery of Selenium and Tellurium at CCR, a Division of Noranda Mines Ltd.,” Proceedings of the Symposium on Industrial Uses of Selenium and Tellurium, Toronto, Canada (October 1980).

Bertrand Lessard, “Anode Slimes Treatment in a Top Blown Rotary Converter at the CCR Division of Noranda Minerals Inc.,” Precious Metals 1989, ed. B. Harris (Allen-town, PA: Intl. Prec. Metals Inst., 1989), pp. 427–440.

B.H. Morrison, “Recovery of Silver and Gold from Refinery Slimes at Canadian Copper Refiners,” Extractive Metallurgy 1985 (London, U.K.: the Institution of Mining and Metallurgy, 1985), pp. 249–269.

B.H. Morrison, J.G. Lenz, J. Pageau and J.G. Bard, “Treatment of Anode Slimes in a Top-Blown Rotary Converter,” U.S. patent 4,581,064 (April 8, 1986).

B.H. Morrison, “The Evolution of Copper Refinery Slime Processing and Precious Metal Treatment at CCR Division—Noranda Minerals,” op. cit. 6, pp. 403–413.

C.P. Dixon, “Gold and Silver Refining at Electrolytic Refining and Smelting Company of Australia Ltd., Port Kembla, N.S.W.,” Mining and Metallurgical Practices in Australasia (The Sir Maurice Mawley Memorial Volume), ed. J.T. Woodcock, Monograph Series No. 10 (Parkville, Victoria, Aus.: The Australasian Inst. Min. Metall., 1980), pp. 519–521.

C.P. Dixon, “Selenium Recovery at The Electrolytic Refining and Smelting Company of Australia Ltd., Port Kembla, N.S.W.,” op. cit. 10, pp. 628–629.

R.K. Monahan and F. Loewen, “Treatment of Anode Slimes at the Inco Copper Refinery,” Canadian Institute of Mining and Metallurgy Annual Conference, Halifax, Nova Scotia (August 1972).

T.S. Sanmiya, R.R. Matthews and D.G. Kerfoot, “Refining Silver-Bearing Residues,” Canadian patent 981, 911 (January 20, 1976).

T.S. Sanmiya and R.R. Matthews, “Oxygen Refining of Smelted Silver Residues,” Precious Metals, ed. R.O. McGachie and A.G. Bradley (Toronto, Canada: Pergamon Press Canada Ltd., 1981), pp. 101–111.

K.N. Subramanian, M.C.E. Bell, J.A. Thomas and N.C. Nissen, “Recovery of Metal Values from Anode Slimes,” U.S. patent 4,229,270 (Oct. 21, 1980); also in Chem. Abs., 94 (1981), no. 9288.

T. De Decker, A. Backx and A. Van Peteghem, “Leaching of Copper Refinery Slimes” (paper presented at 1976 AIME Annual Meeting, Las Vegas, Nevada).

I. Fujimura and A. Katai, “Selenium Recovery from Copper Electrolysis Slimes at Mitsubishi Osaka Refinery,” TMS Paper A82-12 (Warrendale, PA: TMS-AIME, 1982).

I. Hyvärinen, E. Rosenberg, L. Lindroos and E. Yllö, “Selenium and Precious Metals Recovery from Copper Anode Slimes at the Outokumpu Pori Refinery,” Precious Metals: Mining, Extraction and Processing, ed. V. Kudryk, D.A. Corrigan and W.W. Liang (Warrendale, PA: TMS, 1984), pp. 537–548.

J.E. Hoffmann, P.D. Parker and A.C. Sabo, “Extraction and Purification of Silver from Sulfates,” U.S. patent 3,996,046 (December 7, 1976).

D. Kunev, Kh. Vasilev, M. Chimbulev and L. Karag'ozov, “Study of the Sulfation Roasting of Electrolytic Copper Slimes,” Metallurgiya (Sofia), 32(8) (1977), pp. 14–16; also in Chem. Abs., 88 (1978), no. 64561.

A.A. Tishchenko, “Extraction of Selenium and Tellurium from Copper Electrolytic Slimes,” Sb. Nauchn. Tr., Ural'sk. Politekhn. Inst. No. 134 (1963), pp. 27–31; also in Chem. Abs., 61 (1964), no. 3955.

J.E. Hoffmann, “Recovery of Selenium from Electrolytic Copper Refinery Slimes,” op. cit. 18, pp. 495–515.

Nippon Shin Kinzoku K.K., “Recovery of Tellurium and Copper in Slime from Copper Electrorefining,” Jpn. Kokai Tokkyo Koho, 81(84) (July 9, 1981), p. 428; also in Chem. Abs., 95 (1981), no. 207402.

V.M. Savin, “Selecting the Most Efficient Method of Treating Slimes Obtained During Electrolytic Copper Refining,” Tsvetn. Met., 38 (8) (1965), pp. 30–38; also in Chem. Abs., 63 (1965), no. 14437.

G. Yildirim and F.Y. Bor, “Hydrometallurgical Treatment of a Copper Refinery Slime Rich in Selenium and Tellurium,” Erzmetall, 38(4) (1985), pp. 196–199.

J.H. Schloen and E.M. Elkin, “The Treatment of Electrolytic Copper Refinery Slimes,” Copper: The Science and Technology of the Metal, Its Alloys and Compounds, ed. A. Butts (New York: Reinhold, 1954), pp. 205–289.

S.A. Vzorodov et al., “Ways to Remove Difficultly Soluble Compounds of Copper and Nickel from Copper-Electrolysis Slimes,” Tsvetn. Met., 10 (1981), pp. 52–54; also in Chem. Abs., 96 (1982), no. 126878.

B.H. Morrison, “Slimes Treatment Process,” U.S. patent 4,047,939 (Sept. 13, 1977).

Nippon Mining Co. Ltd., “Treatment of Anode Slime from Copper Electrolysis,” Jpn. Tokkyo Koho, 80(27) (July 18, 1980), p. 138; also in Chem. Abs. 94 (1981), no. 107170.

T.N. Greiver, “Optimum Temperature Conditions for the Roastingof Copper ElectrolyteSlurries,” Tsvetn.Met., 6 (1974), pp. 16–18; also in Chem. Abs., 81 (1974), no. 172195.

A.B. Titarenko, T.N. Breiver, A.I. Poluboyarinov and A.F. Astakhov, “Reconstruction of the Slimes Department of the Pyshma Electrolytic Copper Plant,” Tsvetn. Met., 2 (1976), pp. 35–36; also in Chem. Abs., 85 (1976), no. 8591.

E.A. Buketov et al., “Shaft Furnace Sintering of Electrolytic Copper Slimes,” Tsvetn. Met., 38(4) (1965), pp. 28–31; also in Chem. Abs., 63 (1966), no. 12722.

V.G. Shkodin et al., “Roasting-Sintering of Anode Slimes with Soda in Shaft Furnaces,” Tr. Ural. Nauch.-Issled. Proekt. Inst. Mednoi Prom, no. 12 (1969), pp. 204–208; also in Chem. Abs., 72 (1970), no. 114078.

G.S. Victorovich, M.C. Bell, R. Sridhar and J. Raskauskas, “Novel Soda Ash Process for the Recovery of Selenium from Anode Slimes” (paper presented at the 109th AIME Annual Meeting, Las Vegas, Nevada, Feb. 1980).

B.H. Morrison, “The Recovery and Separation of Selenium and Tellurium by Pressure Leaching of Copper Refinery Slime,” Met. Soc. Conf., 24 (1963), pp. 227–249.

K.G. Tan and P.L. Bedard, “Ammonia Leach Process for the Treatment of Copper Refinery Anode Slimes Containing High Lead and Low Nickel,” Can. Met. Quart., in press.

K.G. Tan, “Fulminating Gold and Silver,” CIM Bulletin, 80(903) (1987), pp. 96–97.

Takeo Ishihara, “The Fundamentals of Selenium Metallurgy. I. Oxidizing Roasting of Silver and Copper Selenides,” Kyushu Kozan Gakkai-shi, 28 (1960), pp. 519–533; also in Chem. Abs., 55 (1961), no. 13783.

S. Lowschau, “Recovery of Selenium from Anode Slime from Electrolytic Copper Refining,” Freiberger Forschungshefte, 60 (1961), pp. 7–30; also in Chem. Abs., 57 (1962), no. 6871.

Takeo Ishihara, “The Fundamentals of Selenium Metallurgy. III. Sulfatizing Roasting of Selenides of Silver and Copper,” Kyushu Kozan Gakkai-shi, 29 (1961), pp. 22–28.; also in Chem. Abs., 55 (1961), no. 13784.

A.A. Tishchenko and V.I. Smirnov, “Formation of Sodium Selenite and Selenate during Sintering of Silver Selenide with Soda Ash,” Izv. Vysshiky Uchebn. Zavedenii, Tsvetn. Met., 5(3) (1962), pp. 49–52.

A.A. Tishchenko and V.I. Smirnov, “Thermodynamics and Experimental Investigation of the Formation Reactions of Sodium Selenite and Sodium Selenate by Sintering Copper Selenide with Soda Ash,” Dokl. Akad. Nau. SSSR, 145(1962), pp. 863–866; also in Chem. Abs., 58 (1963), no. 2171.

A.A. Tishchenko and V.I. Smirnov, “Study of Conditions for the Formation of Sodium Selenites and Selenates by Sintering Silver and Copper Selenides with Sodium Carbonate,” Zh. Prikl. Khim., 36(11) (1963), pp. 2363–2367; also in Chem. Abs., 60 (1964), no. 6511.

S. Yanagida, N. Hosada and M. Tanaka, “Flotation of Anode Slime in Copper Electrolysis,” Nippon Kogyo Kaishi, 91 (1046) (1975), pp. 308–310; also in Chem. Abs., 87 (1977), no. 170955.

Chuanya Lei and Peihua Zhu, “Recovery of Precious Metals from Copper Anode Slime by Combined Metallurgy and Beneficiation,” Miner. Proc. Extr. Metall., ed. M.J. Jones and P. Gill, (London, U.K.: nst. Min. Metall., 1984), pp. 699–705.

T. Segarceanu, R. Badoiu and G. Busila, “Processing of Anodic Muds from Electrolytic Refining of Copper,” Rom., 65 (Nov. 30, 1978), p. 472; also in Chem. Abs., 92 (1980), no. 26160.

T. Yazaki and K. Tomaki, “Refining of Anode Slime,” Jpn. Kokai Tokkyo Koho, 62(1) (Jan. 7, 1987), p. 830; also in Chem. Abs., 106 (1987), no. 160046.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Cooper, W.C. The treatment of copper refinery anode slimes. JOM 42, 45–49 (1990). https://doi.org/10.1007/BF03221054

Issue Date:

DOI: https://doi.org/10.1007/BF03221054