Abstract

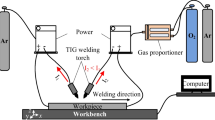

This paper deals with a newly developed pretreatment for TIG arc welding to improve weld penetration. As a pre-treatment, a small oxidized region was produced on the surface of stainless steel plates by laser irradiation using oxygen gas prior to travelling TIG arc. The effect of the pre-treatment (especially named LA pre-treatment) on the TIG weld penetration was evaluated. It was found that the pre-treated region extremely smaller than the weld could make the TIG weld penetration deeper at lower welding speeds.

Similar content being viewed by others

References

Heiple C.R. and Roper J.R.: Mechanism for minor element effect on GTA fusion zone geometry, Welding Journal, 1982, vol. 61, no. 4, pp. 97s–102s.

Mills K.C., Keene B.J., Brooks R.F. and Shirali A.: Marangoni effects in welding, Philosophical Transactions of the Royal Society: Mathematical, Physical and Engineering Sciences, 1998, vol. 356, no. 1739, pp. 911–925.

Pierce S.W., Burgardt P. and Olson D.L.: Thermocapillary and arc phenomena in stainless steel welding, Welding Journal, February 1999, pp. 45s-52s.

Howse D.S. and Lucas W.: Investigation into arc constriction by active fluxes for tungsten inert gas welding, Science and Technology of Welding and Joining, 2000, vol. 5, no. 3, pp. 189–193.

Modenesi P.J., Apolinario E.R. and Pereira I.M.: TIG welding with single-component fluxes, Journal of Materials Processing Technology, 2000, vol. 99, no. 1-3, pp. 260–265.

Katayama S., Mizutani M. and Matsunawa A.: Liquid flow inside molten pool during TIG welding and formation mechanism of bubble and porosity, proceedings of the 7th International Welding Symposium, 2001, J.W.S., Kobe, Japan, pp. 125–130.

Lu S.P., Fujii H., Sughiyama H. and Nogi K.: Mechanism and optimization of oxide fluxes for deep penetration in gas tungsten arc welding, Metallurgical and Materials Transactions A, 2003, vol. 34, no. 9, pp. 1901–1907.

Aidun D.K. and Martin S.A.: Effect of sulfur and oxygen on weld penetration of high-purity austenitic stainless steels, Journal of Materials Engineering and Performance, 1997, vol. 6, no. 4, pp. 496–502.

Saito K. and Ohmizu S.: Effect of steel types and oxygen in argon shielding gas on the penetration of stainless steel TIG welds, Memoirs of Fukui University of Technology, 2000, vol. 30, part 1, pp. 165–172.

Lu S.P., Fujii H., Sugiyama H., Tanaka M. and Nogi K.: Effects of oxygen additions to argon shielding gas on GTA weld shape, ISIJ International, 2003, vol. 43, no.10, pp. 1590–1595.

Lu S.P., Fujii H., Nogi K., Sato T.: Effect of oxygen content in He-O2 shielding gas on weld shape in ultra deep penetration TIG, Science and Technology of Welding and Joining, 2007, vol. 12, No. 8, pp. 689–695.

Fujii H., Sato T., Lu S.P. and Nogi K.: Development of an advanced A-TIG (AA-TIG) welding method by control of Marangoni convection, Materials Science and Engineering A, 2008, vol. 495, pp. 296–303.

Mizutani M., Naito Y. and Katayama S.: High-efficient TIG arc welding process utilizing laser activation (LA-TIG Process) (Report 1) — LA-TIG weldability of Type 304 stainless steel -, Preprints of the National Meeting of J.W.S, 2005, vol. 77, pp. 100–101 (in Japanese).

Mizutani M., Naito Y. and Katayama S.: High-efficient TIG arc welding process utilizing Laser Activation (LA-TIG Process) (Report 2) — Chemical composition analysis of laser-activated zone and LA-TIG weld — Preprints of the National Meeting of J.W.S., 2005, vol. 77, pp. 102–103 (in Japanese).

Mizutani M. and Katayama S.: High-efficient TIG arc welding process utilizing Laser Activation (LA-TIG Process) (Report 3) — Observation of melt flow and arc behavior during LA-TIG arc welding —, Preprints of the National Meeting of J.W.S., 2006, vol. 79, pp. 138–139 (in Japanese).

Tanaka M., Shimizu T., Terasaki H., Ushio M., Koshiishi F. and Yang C.-L.: Effects of activating flux on arc phenomena in gas tungsten arc welding, Science and Technology of Welding and Joining, 2000, vol. 5, no. 6, pp. 397–402.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mizutani, M., Katayama, S. Tig Weld Penetration Improvement by Laser-Activated Process With Oxygen. Weld World 56, 21–29 (2012). https://doi.org/10.1007/BF03321141

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321141