Abstract

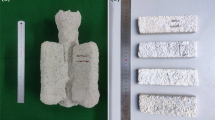

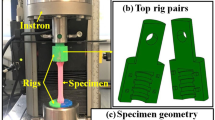

During the investment casting process, the shell is subjected to high internal pressure and thermal stress, particularly during pattern removal and when pouring steel into the free standing ceramic shell. Most testing methods investigate the properties of the ceramic shell in flat regions while cracks typically form in the sharp corners and edge regions. The corners and edge regions have different structure and thickness when compared to flat regions and experience large mechanical stress during processing. In this study, experimental methods were combined with finite element modeling to predict failure stress in the internal corner regions of the shell. The model takes into consideration the mechanical properties of the ceramic shell to determine the stress developed during loading. The effect of shell porosity on stress concentration in sharp corners was evaluated. A general equation was developed to predict the force necessary for crack formation in the shell based on various geometric variables. The results from the model were experimentally verified and the failure stress in flat and corner regions of the shell were compared in order to develop an improved equation.

Similar content being viewed by others

References

Foster, G, “Flashfire Dewax for Today’s Investment Casting Foundry,” Investment Casting Institute 42nd Annual Meeting, pp. 2:1–2:11, Atlanta, Georgia; USA; 25–28 (September 1994).

Yao, W. L.; Leu, Ming C., “Analysis of Shell Cracking in Investment Casting with Laser Stereolithography Patterns,” Rapid Prototyping Journal, vol. 5, no. 1 (March 1999).

Capadona, J.A., “Slurry Process Control in Production can “Crack Down” on Shell Cracking,” Incast, vol. 4, no. 4, pp. 10–12 (April 1991).

Guerra, M., Schiefelbein, G.W., “Review of Shell Components, Shell Characteristics and Properties: Refractory Selection for Primary Shell Coat,” Investment Casting Institute 42nd Annual Meeting, Atlanta, Georgia; USA; 25–28 September 1994.

Kline, D., Controlling Strength and Permeability of Silica Investment Casting Molds, Missouri University of Science and Technology, Thesis, pp. 46–47 (2010).

Kline, D., Lekakh, S., Mahimkar, C., Richards, V., “Crack Formation in Ceramic Shell During Foam Pattern Firing,” Technical and Operating Conference, Chicago, Illinois; USA (December 2009).

Hyde, R., Leyland, S., Withey, P., Jones, S., “Evaluation of the Mechanical Properties of Investment Casting Shells,” 22nd Investment Casting Conference (1995).

Peterson, R. E., “Peterson’s Stress Concentration Factors,” John Wiley and Sons Inc., pp.18–20 (1961).

Kruse, B. L., Richards, V. L., “Thermal and Moisture Characterization during Autoclave Dewaxing in Investment Casting,” Proceedings of the 59th SFSA T&O Conference, No. 5.5 (2005).

Mahimkar, C., Thermo-physical Properties Measurement and Steel-Ceramic Shell Interactions in Investment Casting, Missouri University of Science and Technology, Thesis, pp. 76 (2011).

Nyongesa, F. W., Aduda, B.O., “Fracture Strength of Porous Ceramics: Stress Concentration vs Minimum Solid Area Models,” African Journal of Science and Technology, Science and Engineering Series, vol. 5, no. 2, pp. 19–27 (Dec. 2004).

ASTM C1161, “Standard Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature,” ASTM International, www.astm.org (2002).

ASTM C20, “Standard Test Methods for Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory Brick and Shapes by Boiling Water,” ASTM International, www.astm.org (2000).

ABAQUS Version 6.9. Manual, Dassault Systèmes S.A., Software Applications for FEA & CAE (2009).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Everhart, W., Lekakh, S., Richards, V. et al. Corner Strength of Investment Casting Shells. Inter Metalcast 7, 21–27 (2013). https://doi.org/10.1007/BF03355541

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03355541