Abstract

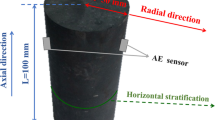

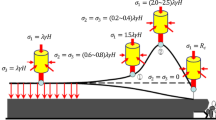

Residual coal pillars play an important role in mining the adjacent coal seam safely, managing the gobs and maintaining the stability of abandoned coal mines. The height to diameter ratio (H/D) affects the stability of residual coal pillars. In this study, uniaxial compressive tests of coal specimens with five H/D (2.0, 1.5, 1.0, 0.8 and 0.6) were performed, and the stress, strain and acoustic emission (AE) were monitored. Results show that the uniaxial compressive strength (UCS) and peak strain increase with H/D decreasing. An empirical equation is proposed to calculate the UCS based on the H/D. The AE activities during coal failure process can be separated into four periods. The span of quiet period and rapid decline period shorten with H/D decreasing. The smaller the H/D is, the more complicated the failure characteristics of coal will be. The failure form of coal with H/D of 2.0, 1.5, and 1.0 is primarily shear failure, while splitting failure along the axial direction is the mainly mode when H/D is 0.8 or 0.6. The initiation, expansion, aggregation and connection of micro-cracks can be reflected by the real-time spatial evolution of AE event points.

摘要

遗留煤柱在相邻煤层安全开采, 采空区管理和维护废弃矿井稳定性等方面发挥着重要作用。高径比影响着遗留煤柱的稳定性。本文对5 种高径比(2.0, 1.5, 1.0, 0.8 和0.6)的煤样进行了单轴压缩试验, 并对应力, 应变和声发射进行了监测。结果表明, 随着高径比的减小, 煤样的单轴抗压强度和峰值应变均增大。提出了一个用以描述单轴抗压强度和高径比关系的经验方程。煤样破坏过程中的声发射活动可被划分为四个时期, 静默期和快速衰弱期的时长与高径比呈正相关。高径比越小, 煤样的破坏特征越复杂, 当高径比为2.0, 1.5, 1.0 时, 破坏形式以剪切破坏为主, 而当高径比为0.8, 0.6 时, 破坏形式以轴向劈裂破坏为主。声发射事件点的实时空间演化可以反映微裂隙的萌生, 扩展, 聚集和联通。

Similar content being viewed by others

References

KARACAN C O, WARWICK P D. Assessment of coal mine methane (CMM) and abandoned mine methane (AMM) resource potential of longwall mine panels: Example from Northern Appalachian Basin, USA [J]. International Journal of Coal Geology, 2019, 208: 37–53. DOI: https://doi.org/10.1016/j.coal.2019.04.005.

POULSEN B A, SHEN B, WILLIAMS D J, HUDDLESTONE-HOLMES C, ERARSLAN N, QIN J. Strength reduction on saturation of coal and coal measures rocks with implications for coal pillar strength [J]. International Journal of Rock Mechanics and Mining Sciences, 2014, 71: 41–52. DOI: https://doi.org/10.1016/j.ijrmms.2014.06.012.

ZHANG Yu-jiang, FENG guo-rui, ZHANG Min, REN Hong-rui, BAI Jin-wen, GUO Yu-xia, JIANG Hai-na, KANG Li-xun. Residual coal exploitation and its impact on sustainable development of the coal industry in China [J]. Energy Policy, 2016, 96: 534–541. DOI: https://doi.org/10.1016/j.enpol.2016.06.033.

ISIAKA A I, DURRHEIM R J, MANZI M S D. High-resolution seismic reflection investigation of subsidence and sinkholes at an abandoned coal mine site in south africa [J]. Pure and Applied Geophysics, 2019, 176(4): 1531–1548. DOI: https://doi.org/10.1007/s00024-018-2026-3.

FENG Guo-rui, WANG Peng-fei, CHUGH Y P. Stability of gate roads next to an irregular yield pillar: A case study [J]. Rock Mechanics and Rock Engineering, 2019, 52(8): 2741–2760. DOI: https://doi.org/10.1007/s00603-018-1533-y.

BAI Jin-wen, FENG Guo-rui, WANG Ze-hua, WANG Shang-yong, QI Ting-ye, WANG Peng-fei. Experimental investigations on the progressive failure characteristics of a sandwiched coal-rock system under uniaxial compression [J]. Applied Sciences, 2019, 9(6): 1195. DOI: https://doi.org/10.3390/app9061195.

HAUQUIN T, GUNZBURGER Y, DECK O. Predicting pillar burst by an explicit modelling of kinetic energy [J]. International Journal of Rock Mechanics and Mining Sciences, 2018, 107: 159–171. DOI: https://doi.org/10.1016/j.ijrmms.2018.05.004.

WANG Fang-tian, TU Shi-hao, LI Zhao-xin, TU Hong-sheng, CHEN Fang. Mutation instability mechanism of the room mining residual pillars in the shallow depth seam [J]. Journal of Mining & Safety Engineering, 2012, 29(6): 770–775. DOI: CNKI:SUN:KSYL.0.2012-06-003. (in Chinese)

ZHU Wei-bing, CHEN Lu, ZHOU Zi-long, SHEN Bao-tang, XU Yu. Failure propagation of pillars and roof in a room and pillar mine induced by longwall mining in the lower seam [J]. Rock Mechanics and Rock Engineering, 2019, 52(4): 1193–1209. DOI: https://doi.org/10.1007/s00603-018-1630-y.

WANG Qi, GAO Hong-ke, JIANG Bei, LI Shu-cai, HE Man-chao, QIN Qian. In-situ test and bolt-grouting design evaluation method of underground engineering based on digital drilling [J]. International Journal of Rock Mechanics and Mining Sciences, 2021, 138: 104575. DOI: https://doi.org/10.1016/j.ijrmms.2020.104575.

DAS M N. Influence of width/height ratio on post-failure behaviour of coal [J]. International Journal of Mining and Geological Engineering, 1986, 4(1): 79–87. DOI: https://doi.org/10.1007/BF01553759.

OZKAN I, OZARSLAN A, GENIS M, OZSEN H. Assessment of scale effects on uniaxial compressive strength in rock salt [J]. Environmental and Engineering Geoscience, 2009, 15(2): 91–100. DOI: https://doi.org/10.2113/gseegeosci.15.2.91.

QI Cheng-zhi, WANG Ming-yang, BAI Ji-ping, LI Kai-rui. Mechanism underlying dynamic size effect on rock mass strength [J]. International Journal of Impact Engineering, 2014, 68: 1–7. DOI: https://doi.org/10.1016/j.ijimpeng.2014.01.005.

HE Gui-cheng, LI Yu-lan, DING De-xin. Experimental investigation on strength and size effect of the gypsum sample in different height to diameter ratios [J]. Chinese Journal of Underground Space and Engineering, 2016, 12(6): 1464–1470. DOI: CNKI:SUN:BASE.0.2016-06-006. (in Chinese)

STAVROU A, MURPHY W. Quantifying the effects of scale and heterogeneity on the confined strength of micro-defected rocks [J]. International Journal of Rock Mechanics and Mining Sciences, 2018, 102: 131–143. DOI: https://doi.org/10.1016/j.ijrmms.2018.01.019.

ZHANG Qi, ZHU He-hua, ZHANG Lian-yang, DING Xiao-bin. Study of scale effect on intact rock strength using particle flow modeling [J]. International Journal of Rock Mechanics and Mining Sciences, 2011, 48(8): 1320–1328. DOI: https://doi.org/10.1016/j.ijrmms.2011.09.016.

POULSEN B A, ADHIKARY D P. A numerical study of the scale effect in coal strength [J]. International Journal of Rock Mechanics and Mining Sciences, 2013, 63: 62–71. DOI: https://doi.org/10.1016/j.ijrmms.2013.06.006.

BAHRANI N, KAISER P K. Numerical investigation of the influence of specimen size on the unconfined strength of defected rocks [J]. Computers and Geotechnics, 2016, 77: 56–67. DOI: https://doi.org/10.1016/j.compgeo.2016.04.004.

WANG Y, FENG W K, HU R L, LI C H. Fracture evolution and energy characteristics during marble failure under triaxial fatigue cyclic and confining pressure unloading (FC-CPU) conditions [J]. Rock Mechanics and Rock Engineering, 2021, 54: 799–818. DOI: https://doi.org/10.1007/s00603-020-02299-6.

MA Xiao-dong. Volumetric deformation, ultrasonic velocities and effective stress coefficients of St Peter sandstone during poroelastic stress changes [J]. Rock Mechanics and Rock Engineering, 2019, 52(9): 2901–2916. DOI: https://doi.org/10.1007/s00603-019-01750-7.

KONG Xiang-guo, WANG En-yuan, HE Xue-qiu, ZHAO En-lai, ZHAO Chuan. Mechanical characteristics and dynamic damage evolution mechanism of coal samples in compressive loading experiments [J]. Engineering Fracture Mechanics, 2019, 210: 160–169. DOI: https://doi.org/10.1016/j.engfracmech.2018.04.005.

LIU Xiao-ming, WU Shao-peng, YANG Xiao-li. Smart characteristics of conductive asphalt concrete [J]. Journal of Central South University of Technology (Science and Technology), 2009, 40(5): 1465–1470. DOI: JournalArticle/5af4a7fec095d718d81c3c00. (in Chinese)

YANG Yong-liang, ZHENG Kai-yue, LI Zhi-wei, LI Zeng-hua, SI Lei-lei, HOU Shi-song, DUAN Yu-jian. Experimental study on pore-fracture evolution law in the thermal damage process of coal [J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 116: 13–24. DOI: https://doi.org/10.1016/j.ijrmms.2019.03.004.

HAN Peng-ju, WANG Shuai, CHEN You-jia, BAI Xiao-hong. Mechanism of cement-stabilized soil polluted by magnesium sulfate [J]. Journal of Central South University, 2015, 22(5): 1869–1877. DOI: https://doi.org/10.1007/s11771-015-2706-4.

ZHU Zhen-de, NI Xiao-hui, WANG Wei, LI Shuang-bei, ZHAO Jie, WU Yi-quan. Dynamic experimental study on rock meso-cracks growth by digital image processing technique [J]. Journal of Central South University of Technology, 2008, 15(S2): 114–120. DOI: https://doi.org/10.1007/s11771-008-0445-5.

XIAO Jia, WANG Jian-hua, CHEN Lei, ZHAO Jin-hui. Damage mechanism of cement-ground limestone cementitious material under sulfate attack condition [J]. Journal of Central South University of Technology (Science and Technology), 2009, 40(1): 230–235. DOI: CNKI:SUN:ZNGD.0.2009-01-042. (in Chinese)

DU Xian-jie, FENG Guo-rui, QI Ting-ye, GUO Yu-xia, ZHANG Yu-jiang, WANG Ze-hua. Failure characteristics of large unconfined cemented gangue backfill structure in partial backfill mining [J]. Construction and Building Materials, 2018, 194: 257–265. DOI: https://doi.org/10.1016/j.conbuildmat.2018.11.038.

XIAO Peng, LI Di-yuan, ZHAO Guo-yan, ZHU Quan-qi, LIU Huan-xin, ZHANG Chun-shun. Mechanical properties and failure behavior of rock with different flaw inclinations under coupled static and dynamic loads. [J]. Journal of Central South University, 2020, 27(10): 2945–2958. DOI: https://doi.org/10.1007/s11771-020-4520-x.

ZHAO Guo-yan, WANG En-jie, WU Hao, QIU Ju, DAI Yi-wen. Micro-fracture evolution rule of sandstone specimens with a single hole under uniaxial compression [J]. Journal of Central South University of Technology (Science and Technology), 2019, 50(8): 1891–1900. DOI: CNKI:SUN:ZNGD.0.2019-08-017. (in Chinese)

LI De-xing, WANG En-yuan, KONG Xiang-guo, ZHAO Shuai, KONG Yan-hui, WANG Xiao-ran, WANG Dong-ming, LIU Quan-lin. Mechanical properties and electromagnetic radiation characteristics of concrete specimens after exposed to elevated temperatures [J]. Construction and Building Materials, 2018, 188: 381–390. DOI: https://doi.org/10.1016/j.conbuildmat.2018.07.236.

WAN Guo-xiang, LI Xi-bing, WANG Qi-sheng. Effect of linear joint on propagation of rock electromagnetic emission [J]. Journal of Central South University (Science and Technology), 2011, 42(4): 1133–1139. DOI: CNKI:SUN:ZNGD.0.2011-04-045. (in Chinese)

YANG Wei-min, GENG Yang, ZHOU Zong-qing, LI Lian-chong, DING Ruo-song, WU Zhong-hu, ZHAI Ming-yang. True triaxial hydraulic fracturing test and numerical simulation of limestone [J]. Journal of Central South University, 2020, 27(10): 3025–3039. DOI: https://doi.org/10.1007/s11771-020-4526-4.

CHU Chao-qun, WU Shun-chuan, ZHANG Shi-huai, GUO Pei, ZHANG Min. Mechaincal behavior anisotropy and fracture characteristics of bedded sandstone [J]. Journal of Central South University (Science and Technology), 2020, 51(8): 2232–2246. DOI: CNKI:SUN:ZNGD.0.2020-08-018. (in Chinese)

CHEN Xu, TANG Chun-an, YU Jin, ZHOU Jian-feng, CAI Yan-yan. Experimental investigation on deformation characteristics and permeability evolution of rock under confining pressure unloading conditions [J]. Journal of Central South University, 2018, 25(8): 1987–2001. DOI: https://doi.org/10.1007/s11771-018-3889-2.

YANG Hui-ming, WEN Guang-cai, HU Qian-ting, LI Yuanyuan, DAI Lin-chao. Experimental investigation on influence factors of acoustic emission activity in coal failure process [J]. Energies, 2018, 11(6): 1414. DOI: https://doi.org/10.3390/en11061414.

ZHANG Shi-hua, WU Shun-chuan, CHU Chao-yun, GUO Pei, ZHANG Guang. Acoustic emission associated with self-sustaining failure in low-porosity sandstone under uniaxial compression [J]. Rock Mechanics and Rock Engineering, 2019, 52(7): 2067–2085. DOI: https://doi.org/10.1007/s00603-018-1686-8.

SHKURATNIK V L, FILIMONOV Y L, KUCHURIN S V. Experimental investigations into acoustic emission in coal samples under uniaxial loading [J]. Journal of Mining Science, 2004, 40(5): 458–464. DOI: https://doi.org/10.1007/s10913-005-0030-3.

LI De-xing, WANG En-yuan, KONG Xiang-guo, ALI M, WANG Dong-ming. Mechanical behaviors and acoustic emission fractal characteristics of coal specimens with a preexisting flaw of various inclinations under uniaxial compression [J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 116: 38–51. DOI: https://doi.org/10.1016/j.ijrmms.2019.03.022.

ULUSAY R. The ISRM suggested methods for rock characterization, testing and monitoring: 2007–2014 [M]// Springer International Publishing, 2015, 74(4): 47–48. DOI: https://doi.org/10.1007/s10064-015-0780-3.

LIU Gang, XIAO Fu-kun, QIN Tao. Rock mechanics characteristics and acoustic emission rule under small-size effect [J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(S2): 3905–3917. DOI: CNKI:SUN:YSLX.0.2018-S2-012. (in Chinese)

MENG Qing-bin, HAN Li-jun, PU Hai, LI Hao, WEN Sheng-yong. Effect of the size and strain rate on the mechanical behavior of rock specimens [J]. Journal of China University of Mining & Technology, 2016, 45(2): 233–243. DOI: CNKI:SUN:ZGKD.0.2016-02-006CNKI:SUN:ZGKD.0.2016-02-006. (in Chinese)

YANG Sheng-qi, SU Cheng-dong, XU Wei-ya. Experimental and theoretical study of size effect of rock material [J]. Engineering Mechanics, 2005, 22(4): 112–118. DOI: https://doi.org/10.3969/j.issn.1000-4750.2005.04.022. (in Chinese)

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation item

Projects(51974192, 52004172) supported by the National Natural Science Foundation of China; Project(51925402) supported by the Distinguished Youth Funds of National Natural Science Foundation of China; Project(U1710258) supported by the Joint Funds of National Natural Science Foundation of China and Shanxi Province, China

Contributors

The overarching research goals were developed by GUO Yu-xia, FENG Guo-rui and ZHAO Yong-hui. ZHAO Yong-hui and GUO Yu-xia did experiment and analyzed the experimental data. The initial draft of the manuscript was written by GUO Yu-xia and ZHAO Yong-hui. WANG Sheng-wei, ZHANG yu-jiang, FENG guo-rui, RAN Hong-yu revised the original manuscript. All the authors replied to the reviewers’ comments and revised the final version.

Conflict of interest

GUO Yu-xia, ZHAO Yong-hui, WANG Sheng-wei, ZHANG yu-jiang, FENG Guo-rui and RAN Hong-yu declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Guo, Yx., Zhao, Yh., Wang, Sw. et al. Stress-strain-acoustic responses in failure process of coal rock with different height to diameter ratios under uniaxial compression. J. Cent. South Univ. 28, 1724–1736 (2021). https://doi.org/10.1007/s11771-021-4729-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4729-3

Key words

- residual coal pillar

- height to diameter ratio

- uniaxial compression

- acoustic emission

- micro-crack evolution