Abstract

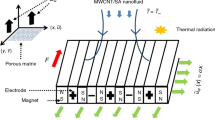

A coupled cellular automaton–finite-element mathematical model has been developed to investigate the multiscale phenomena of the electroslag remelting (ESR) H13 steel ingot. The heat transfer equation is solved to obtain the temperature distribution and liquid metal pool profile by a coarser finite-element (FE) mesh. Then, a regular network of square cells with a much finer scale is drawn for the simulation of microstructure with the cellular automaton (CA) technique. The continuous nucleation, which is based on the Gaussian distribution, is implemented to describe the heterogeneous nucleation. The growth kinetics of the dendritic tip is taken into account by the Kure–Giovanola–Trivedi model. At each time step, the temperature at the CA cell locations is interpolated from the temperature at four adjacent FE elements. The solute transfer is calculated using the FE method. Moreover, the evolution of the multiscale phenomena with growing of the ingot is considered by the varying boundary conditions. A reasonable agreement is demonstrated between the calculation and experiment. The results indicate that the shallow U-shaped metal pool would change to the deep V-shaped metal pool with the growing of the ingot. The vertical columnar grains appear at the bottom of the ingot, and an inverse V-shaped grain structure can be observed at the upper part of the ingot. It can be inferred that improving the undercooling can refine the microstructure and motivate the growing of the columnar grain during the ESR process.

Similar content being viewed by others

References

A. Kharicha, A. Ludwig, and M. Wu, Mater. Sci. Eng. A 413, 129 (2005).

V. Weber, A. Jardy, B. Dussoubs, D. Ablitzer, S. Rybéron, V. Schmitt, S. Hans, and H. Poisson, Metall. Mater. Trans. B 42B, 271 (2009).

B.K. Li, F. Wang, and F. Tsukihashi, ISIJ Int. 52, 1289 (2012).

B. Hernandez-Morales and A. Mitchell, Ironmak. Steelmak. 26, 423 (1999).

A. Mitchell, Mater. Sci. Eng. A 413, 10 (2005).

M. Ode, S.G. Kim, and T. Suzuki, ISIJ Int. 41, 1076 (2001).

K. Oguchi and T. Suzuki, ISIJ Int. 47, 277 (2007).

K. Oguchi and T. Suzuki, ISIJ Int. 47, 1432 (2007).

J.A. Spittle and S.G.R. Brown, J. Mater. Sci. 23, 1777 (1989).

J.A. Spittle and S.G.R. Brown, Acta Metall. Mater. 37, 1803 (1989).

M. Rappaz and Ch-A Gandin, Acta Metall. Mater. 41, 345 (1993).

G. Guillemot, Ch-A Gandin, and H. Combeau, ISIJ Int. 46, 880 (2006).

Ch-A Gandin and M. Rappaz, Acta Mater. 45, 2187 (1997).

Ch-A Gandin and M. Rappaz, Acta Metall. Mater. 42, 2233 (1994).

Ch-A Gandin, J.-L. Desbiolles, M. Rappza, and Ph Thevoz, Metall. Mater. Trans. A 30A, 3153 (1999).

B. Su, Z.Q. Han, and B.C. Liu, ISIJ Int. 53, 527 (2013).

X. Xu, W. Zhang, and P.D. Lee, Metall. Mater. Trans. A 33A, 1805 (2002).

Y. Zhao, D.F. Chen, M.J. Long, T.T. Arif, and R.S. Qin, Metall. Mater. Trans. B 45B, 719 (2013).

B. Liu and Q. Xu, Metall. Mater. Trans. B 38B, 525 (2007).

S. Luo, M.Y. Zhu, and S. Louhenkilpi, ISIJ Int. 52, 823 (2012).

L. Nastac, S. Sundarraj, K.-O. Yu, and Y. Pang, JOM 50 (3), 30 (1998).

M. Rappaz, Int. Mater. Rev. 34, 93 (1989).

P. Thevoz, J.L. Desbiolles, and M. Rappaz, Metall. Trans. A 20A, 311 (1989).

D.E. Ovsienko, G.A. Alfintsev, and V.V. Maslov, J. Cryst. Growth 26, 233 (1974).

W. Kurz and R.N. Grugel, Mater. Sci. Forum 77, 185 (1991).

W. Kurz, B. Giovanola, and R. Trivedi, Acta Metall. 34, 823 (1986).

L. Nastac, Acta Mater. 47, 4253 (1999).

M. Choudhary and J. Szekely, Metall. Trans. B 11B, 439 (1980).

A. Jardy, D. Ablitzer, and J.F. Wadier, Metall. Trans. B 22B, 111 (1991).

Y.Y. Sheng, G.A. Irons, and D.G. Tisdale, Metall. Mater. Trans. B 29B, 85 (1998).

A. Mitchell and B. Hernandez-Morales, Metall. Trans. B 21B, 723 (1990).

D. Kashchiev, A. Borissova, R.B. Hammond, and K.J. Robert, J. Phys. Chem. B 116, 5441 (2010).

J. Wang, F. Wang, C. Li, and J. Zhang, ISIJ Int. 50, 222 (2010).

Ch-A Gandin, M. Rappaz, and R. Tintillier, Metall. Trans. A 24A, 467 (1993).

Acknowledgements

The authors’ gratitude goes to National Natural Science Foundation of China (No. 50934008) and National Natural Science Foundation of China (No. 51210007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, B., Wang, Q., Wang, F. et al. A Coupled Cellular Automaton–Finite-Element Mathematical Model for the Multiscale Phenomena of Electroslag Remelting H13 Die Steel Ingot. JOM 66, 1153–1165 (2014). https://doi.org/10.1007/s11837-014-0979-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-0979-y