Abstract

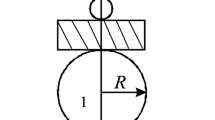

Fracture-toughness measurements were made on standard three-point-bend fracture specimens of Indiana limestone. Specimen dimensions, experimental techniques, and methods of data reduction were chosen to comply as closely as possible to the Tentative Method of Test for Plane Strain Fracture Toughness of Metallic Materials (ASTM Designation: E399-72T). Typical strain-gage-type clip-in displacement gages were found to lack the necessary sensitivity for measuring the crack-opening displacement while an LVDT displacement transducer having a linear range of ±0.25 mm (±0.010 in.) was found to be ideal.

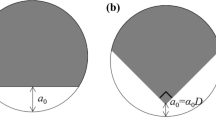

Fatigue cracks were successfully introduced by repeated cycling to 85 percent of the fracture load. Load vs. crack opening-displacement records indicated that crack closure occurred in these tests. Effective crack lengths were determined using an experimental compliance calibration that was checked analytically. Final fracture was stable when using displacement control in a stiff load frame. Some size effects were noted, with toughness increasing with specimen size. Values ofK c, fracture toughness, were found to approach 990 kNm−3/2 (900\(psi\sqrt {in} \).) for the largest specimens.

Similar content being viewed by others

References

“Tentative Method of Test for Plane Strain Fracture Toughness of Metallic Materials (ASTM Designation: E399-72T),” 1972 Annual Book of Standards, Part 31, ASTM, Phila. (1972).

Srawley, J. E. and Brown, Jr., W. F., “Fracture Toughness Test Methods, Fracture Toughness Testing and its Applications,” ASTM STP 381, ASTM, 133 (1965).

McClintock, F. A. and Walsh, J. B., “Friction on Griffith Cracks in Rocks under Pressure,” Proc. Fourth U.S. Nat. Congr. App. Mech., 1015–1021 (1962).

Hardy, M. P., “Fracture Mechanics Applied to Rock,” Ph.D. thesis, University of Minnesota (Dec. 1973).

Griffith, A. A., “The Theory of Rupture,” Proc. of First Int'l. Cong. on Appl. Mech., 55 (1924).

Orowan, E., Fatigue and Fracture of Metals, Proc. of 1950 Conf. at M.I.T., John Wiley, N.Y., 139 (1952).

Irwin, G. R., “Analysis of Stresses and Strains Near the End of a Crack Traversing a Plate,”J. of Appl. Mech.,24,361 (1957).

Rice, J. R., “A Path Independent Integral and the Approximate Analysis of Strain Concentration by Notches and Cracks,”J. of App. Mech.,35,379 (1968).

Fairhurst, C., “On the Validity of the ‘Brazilian’ Test for Brittle Materials,”Int. J. Rock Mech. Min. Sci.,1,535 (1964).

Peng, S. andJohnson, A. M., “Crack Growth and Faulting in Cylindrical Specimens of Chelmsford Granite,”Int. J. Rock Mech. Min. Sci.,9,37 (1972).

Krech, W. W., “The Energy Balance Theory and Rock Fracture Energy Measurements for Uniaxial Tension,” Advances in Rock Mechanics, Proc. of Third Int'l. Soc. Rock Mech. Cong.,2-A,167 (1974).

Brown, W. S., Swanson, S. R., and Mason, W. E., “Fracture Mechanics Applications to Rock,” Rept. to B. of Mines on ARPA Order No. 1579, Amend. No. 2,Univ. of Utah (Feb. 1972).

Johnson, J. N., Clifton, R. J., Simonson, E. R., and Green, S. J., “Analysis of Fracture for Hollow Cylindrical and Spherical Rock Specimens subject to Internal Pressure with Application to Underground Nuclear Containment,” Terra Tek report on Contract No. DNA 001-73-C-0153, Salt Lake City, Utah (1973).

Handin, J. and Friedman, M., “Mechanical Properties of Rocks Related to Drilling Technology,” Second Quarterly Progress Report to Sandia Laboratories on Contract No. 82-9473 (1974).

Callender, J., Geology Department, University of New Mexico, private communication (1975).

Gross, B., Roberts, E., and Srawley, J. E., “Elastic Displacements for Various Edge-Cracked Plate Specimens,” NASA Technical Note TN D-4232, NASA (November 1967).

Hoagland, R. G., Hahn, G. T., andRosenfield, A. R., “Influence of Microstructure on Fracture Propagation in Rock,”Rock Mech.,5,77–106 (1973).

Paris, P. C., “The Fracture Mechanics Approach to Fatigue,” Fatigue—”An Interdisciplinary Approach, Syracuse University Press, Syracuse, N.Y., 107 (1965).

Johnson, H. H. andParis, P. C., “Subcritical Flaw Growth,”Engrg. Fract. Mech.,1,3 (1968).

Schmidt, R. A. and Paris, P. C., “Threshold for Fatigue Crack Propagation and the Effects of Load Ratio and Frequency,” Progress in Flaw Growth and Fracture Toughness Testing, ASTM STP 536, 79–94 (1973).

Elber, W., “The Significance of Fatigue Crack Closure,” Damage Tolerance in Aircraft Structures, ASTM STP 486, 230 (1971).

Pitoniak, F. J., Grandt, A. F., Montalli, L. T., andPackman, P. F., “Fatigue Crack Retardation and Closure in Polymethylmethacrylate,”Engrg. Fract. Mech.,6,663–670 (1974).

Srawley, J. E., “Plane Strain Fracture Toughness,”Fracture—An Advanced Treatise, Academic Press, N.Y.,IV,45–68 (1969).

Brown, Jr., W. F. and Srawley, J. E., “Plane Strain Crack Toughness Testing of High Strength Metallic Materials,” ASTM STP 410, ASTM, 1–65 (1966).

Hardy, Jr., H. R. andJoyaramon, N. I., “An Investigation of Methods for the Determination of the Tensile Strength of Rock,”Proc. of Second Cong. of Int'l. Soc. for Rock Mech.,3,85 (1970).

Hickerson, J. P., “Elements of Experimental Fracture Mechanics,” Sandia Laboratories Report SLA-73-0424 (March 1974).

Schmidt, R. A., Unpublished Fracture Toughness Data on Charcoal Granite (1975).

Nelson, F. G., Schilling, P. E., andKaufman, S. G., “The Effect of Specimen Size on the Results of Plane-Strain Fracture-Toughness Tests,”Engrg. Fract. Mech.,4,33 (1972).

Jones, M. H. and Brown, Jr., W. F., “The Influence of Crack Length and Thickness in Plane-Strain Fracture Toughness Tests,” ASTM STP 463, ASTM, 63 (1970).

Author information

Authors and Affiliations

Additional information

Work was supported by the U.S. Energy Research and Development Administration.

Rights and permissions

About this article

Cite this article

Schmidt, R.A. Fracture-toughness testing of limestone. Experimental Mechanics 16, 161–167 (1976). https://doi.org/10.1007/BF02327993

Issue Date:

DOI: https://doi.org/10.1007/BF02327993