Abstract

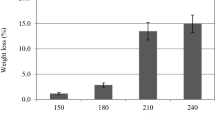

Finnish wood heat treatment technology, ThermoWood, was recently introduced to Québec, Canada by Ohlin Thermo Tech. Subsequently, a large number of initial trials were conducted on five commercially important Québec wood species, spruce (Picea spp.), pine (Pinus spp.), fir (Abies spp.), aspen (Populus spp.), and birch (Betula spp.). These species were thermally-modified in different batches at temperatures of 200 °C or higher. The static bending and hardness of the thermally-modified wood were examined. Decreases of 0% to 49% were observed in modulus of rupture of heat-treated spruce, pine, fir, and aspen depending on species and treatment schedules used; modulus of rupture of birch increased slightly after the heat treatment. The decrease in modulus of elasticity of heat-treated spruce and pine ranged from 4% to 28%; but the modulus of elasticity of heat-treated fir, aspen, and birch increased except one trial for fir. Hardness of the heat-treated wood increased or decreased depending on the species, test directions (radial, tangential, and longitudinal), and treatment schedules.

Zusammenfassung

ThermoWood ist ein aus Finnland stammendes Verfahren zur Wärmebehandlung von Holz, das seit kurzem von Ohlin Thermo Tech in Quebec, Kanada angewendet wird. In diesem Zusammenhang wurden an fünf wirtschaftlich bedeutenden, in Quebec vorkommenden Holzarten, nämlich Fichte (Picea spp.), Kiefer (Pinus spp.), Tanne (Abies spp.), Pappel (Populus spp.) und Birke (Betula spp.), zahlreiche Versuche durchgeführt. Diese Holzarten wurden bei verschiedenen Temperaturstufen von 200 °C oder höher wärmebehandelt, daran anschließend wurden die Biegefestigkeit und Härte des wärmebehandelten Holzes untersucht. Die Biegefestigkeit von wärmebehandelter Fichte, Kiefer, Tanne und Pappel nahm je nach Holzart und Behandlung zwischen 0% und 49% ab; wohingegen die Biegefestigkeit von Birke nach der Behandlung geringfügig höher war. Der Elastizitätsmodul von Fichte und Kiefer nahm zwischen 4 und 28% ab, wohingegen der E-Modul von Tanne, Pappel und Birke mit Ausnahme eines Versuchs bei Tanne zunahm. Die Härte des wärmebehandelten Holzes nahm abhängig von Holzart, Orientierung (radial, tangential und longitudinal) und Behandlung zu oder ab.

Similar content being viewed by others

References

American Society for Testing and Materials (ASTM) (2004) Standard test methods for small clear specimens of timber. D-143-94. Vol. 04.10 on Wood. Annual Book of ASTM Standards, ASTM. West Conshohocken, PA

Bengtsson C, Jermer J, Brem F (2002) Bending strength of heat-treated spruce and pine timber. IRG/WP 02-40242

Callister WD (1994) Materials Science and Engineering: An Introduction. John Wiley and Sons, New York

Chanrion P, Schreiber J (2002) Bois Traité par Haute Température. CTBA, France

Dirol D, Guyonnet R (1993) The improvement of wood durability by retification process. IRG/WP 98-40015

Finnish ThermoWood Association (2003) ThermoWood Handbook. Helsinki, Finland

Kotilainen R (2000) Chemical changes in wood during heating at 150–260 °C. Ph.D. Thesis, Jyväskylä University, Finland

Militz H (2002) Thermal treatment of wood: European processes and their background. IRG/WP 02-40241

Rapp AO, Sailer M (2000) Heat treatment in Germany. Proceedings of Seminar “Production and development of heat treated wood in Europe”, Helsinki, Finland

Sailer M, Rapp AO, Leithoff H (2000) Improved resistance of Scots pine and spruce by application of an oil-heat treatment. IRG/WP 00-40162

Santos JA (2000) Mechanical behaviour of Eucalyptus wood modified by heat. Wood Sci Technol 34:39–43

Syrjänen T, Kangas E (2000) Heat treated timber in Finland. IRG/WP 00-40158

Tjeerdsma BF, Boonstra M, Militz H (1998a) Thermal modification of non-durable wood species. IRG/WP 98-40124

Tjeerdsma BF, Boonstra M, Pizzi A, Tekely P, Militz H (1998b) Characterisation of thermally modified wood: molecular reasons for wood performance improvement. Holz Roh- Werkst 56(3):149–153

Troya MT, De Navarrete AM (1994) Study of the degradation of retified wood through ultrasonic and gravimetric techniques. IRG/WP 94-40030

Vernois M (2001) Heat treatment of wood in France-state of the art. Proceedings of Special Seminar “Review on heat treatments of wood”, Antibes, France

Viitanen HA, Jänsä S, Paajanen LM, Nurmi AJ, Viitaniemi P (1994) The effect of heat treatment on the properties of spruce. IRG/WP 94-40032

Yildiz S (2002) Effects of heat treatment on water repellence and anti-swelling efficiency of beech wood. IRG/WP 02-40223

Yildiz S, Çolakoğlu G, Yildiz ÜC, Gezer ED, Temiz A (2002) Effects of heat treatment on modulus of elasticity of beech wood. IRG/WP 02-40222

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, J.L., Kocaefe, D. & Zhang, J. Mechanical behaviour of Québec wood species heat-treated using ThermoWood process . Holz Roh Werkst 65, 255–259 (2007). https://doi.org/10.1007/s00107-007-0173-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-007-0173-9