Abstract

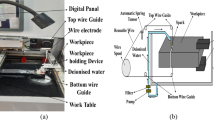

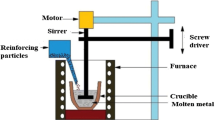

In this investigation, the effect of wire electrical discharge machining (WEDM) parameters such as pulse-on time (T ON), pulse-off time (T OFF), gap voltage (V) and wire feed (F) on material removal rate (MRR) and surface roughness (R a) in metal matrix composites (MMCs) consisting of aluminium alloy (Al6063) and silicon carbide (SiCp) is discussed. The Al6063 is reinforced with SiCp in the form of particles with 5%, 10% and 15% volume fractions. The experiments are carried out as per design of experiments approach using L9 orthogonal array. The results were analysed using analysis of variance and response graphs. The results are also compared with the results obtained for unreinforced Al6063. From this study, it is found that different combinations of WEDM process parameters are required to achieve higher MRR and lower R a for Al6063 and composites. Generally, it is found that the increase in volume percentage of SiC resulted in decreased MRR and increased R a. Regression equations are developed based on the experimental data for the prediction of output parameters for Al6063 and composites. The results from this study will be useful for manufacturing engineers to select appropriate WEDM process parameters to machine MMCs of Al6063 reinforced with SiCp at various proportions.

Similar content being viewed by others

References

Chawla KK (2001) Composite materials science and engineering. Springer, Newyork

Hamatami G, Ramulu M (1990) Machinability of high temperature composites by abrasive water jet. ASME J Eng Mater Technol 112(4):381–386

Muller F, Monahan J (2000) Non-conventional machining of particle reinforced metal matrix composite. Int J Mach Tools Manuf 40:1351–1366

Muller F, Monahan J (2001) Non-conventional machining of particle reinforced metal matrix composites. J Mater Process Technol 118:278–285

Ho KH, Newman ST, Rahimifard S, Allen RD (2004) State of the art in wire electrical discharge machining (WEDM). Int J Mach Tools Manuf 44:1247–1259

Benedict GF (1987) Nontraditional manufacturing processes. Marcel Dekker, Newyork

Garg RK, Singh KK, Sachdeva A, Sharma VS, Ojha K, Singh S (2010) Review of research work in sinking EDM and WEDM on metal matrix composite materials. Int J Adv Manuf Technol. doi:10.1007/s00170-010-2534-5

Adithan M (2009) Unconventional machining process. Atlantic, New Delhi

Konda R, Rajurkar KP, Bishu RR, Guha A, Parson M (1999) Design of experiments to study and optimize process performance. Int J Qual Reliab Manage 16(1):56–71

Gatto A, Iuliano L (1997) Cutting mechanism and surface features of WED machined metal matrix composite. J Mater Process Technol 65:209–214

Rozenek M, Kozak J, Dalbrowski K (2001) Electrical discharge machining characteristics of metal matrix composites. J Mater Process Technol 109:367–370

Guo ZN, Wang X, Huang ZG, Yue TM (2002) Experimental investigation into shaping particles-reinforce material by WEDM-HS. J Mater Process Technol 129:56–59

Yan BH, Tsai HC, Huang FY, Lee LC (2005) Examination of wire electrical discharge machining of Al2O3p/6061Al composites. Int J Mach Tools Manuf 45:251–259

Liu JW, Yue TM, Guo ZN (2009) Wire electrochemical discharge machining of Al2O3 particle reinforced aluminium alloy 6061. Mater Manuf Process 24:446–453

Patil NG, Brahmankar PK (2006) Some investigation into wire electro-discharge machining performance of Al/SiCp Composites. Int J Machin Machin Mater 1(4):412–259

Manna A, Bhattacharya B (2006) Taguchi and Gauss elimination method: a dual response approach for parametric optimization of CNC wire cut EDM of PRAlSiCMMC. Int J Adv Manuf Technol 28:67–75

Akshay D, Pradeep K, Inderdeep S (2008) Experimental investigation and optimization in EDM of Al 6063 SiCp metal matrix composite. Int J Machin Machin Mater 5(3/4):293–308

Park SH (1996) Robust design and analysis for quality engineering. Chapman and Hall, London

Ramulu M, Taya M (1989) EDM machining of SiCw/Al composite. J Mater Sci 24:1103–1108

Hung NP, Yang LJ, Leong KW (1994) Electrical discharge machining of cast metal matrix composites. J Mater Process Technol 44:229–236

Mohan B, Rajadurai A, Satyanarayana KG (2002) Effect of SiC and rotation of electrode on electric discharge machining of Al-SiC composite. J Mater Process Technol 124:297–304

Tosun N, Cogun C, Inan A (2003) The effect of cutting parameters on workpiece surface roughness in wire EDM. Mach Sci Technol 7(2):209–219

Sushant D, Rajesh P, Nishant S, Akhil S, Hemanth KG (2007) Mathematical modeling of electric discharge machining of cast Al-4Cu-6Si alloy-10 wt.% SiCp composites. J Mater Process Technol 194:24–29

Liao YS, Huang JT, Su HC (1997) A study on the machining-parameters optimization of wire electrical discharge machining. J Mater Process Technol 71:487–493

Narender Singh P, Rahukandan K, Rathinasabapathi M, Pai BC (2004) Electric discharge machining of Al-10%SiCp as-cast metal matrix composites. J Mater Process Technol 155–156:1653–1657

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Satishkumar, D., Kanthababu, M., Vajjiravelu, V. et al. Investigation of wire electrical discharge machining characteristics of Al6063/SiCp composites. Int J Adv Manuf Technol 56, 975–986 (2011). https://doi.org/10.1007/s00170-011-3242-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3242-5