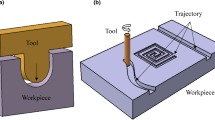

This study investigates the feasibility of improving surface integrity via a novel combined process of electrical discharge machining (EDM) with ball burnish machining (BBM) using the Taguchi method. To provide burnishing immediately after the EDM process, ZrO2 balls were attached to the tool electrode in the experiments. To verify the optimal process, three observed values, i.e. material removal rate, surface roughness, and improvement ratio of surface roughness were chosen. In addition, six independent parameters were adopted for evalu-ation by the Taguchi method. From the ANOVA and S/N ratio response graph, the significant parameters and the optimal combination level of machining parameters were obtained. Experimental results indicate that the combined process effectively improves the surface roughness and eliminates the micro pores and cracks caused by EDM. Therefore, the combination of EDM and BBM is a feasible process by which to obtain a fine-finishing surface and achieve surface modification.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lin, Y., Yan, B. & Huang, F. Surface Improvement Using a Combination of Electrical Discharge Machining with Ball Burnish Machining Based on the Taguchi Method. Int J Adv Manuf Technol 18, 673–682 (2001). https://doi.org/10.1007/s001700170028

Issue Date:

DOI: https://doi.org/10.1007/s001700170028