Abstract

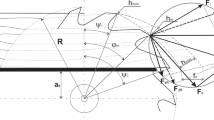

In the present study, the conditions of chip propagation or fracture in orthogonal oblique cutting of beech wood (Fagus silvatica) in the 90°–0° direction for a type-I chip has been investigated. The force required for orthogonal wood cutting is pronouncedly variable, which is the consequence of exchangeable different ways of material breakdown. The chip formation process is discontinuous because of interrupted splitting of the material in front of the cutting tool. A 10-mm-thick specimen was cut at a rake angle of 31° and 42° with chip thicknesses ranging from 0.1 to 0.3 mm. The chip segment length increased with the chip thickness. A chip of varying length and thickness was modelled using the finite element method. For each case, the bending or compressive stress in the chip and the stress intensity factor at the crack tip was calculated. The segment length of the chip can be calculated by taking into account the condition that a crack propagates when the stress intensity factor K I at the crack tip equals the critical stress intensity factor K IC, and the bending or compressive stress σ x in the chip is smaller than the strength σ u . Good agreement between the calculated and the measured values was observed. The chip segment length can change considerably already with small changes in the bending strength and critical stress intensity factor. This large sensitivity is also confirmed by the fluctuation of the measured chip segment lengths by as much as 400%.

Similar content being viewed by others

References

Atkins AG (2003) Modelling metal cutting using modern ductile fracture mechanics: quantitative explanations for some longstanding problems. Int J Mech Sci 45:373–396

Atkins AG (2004) Rosenhain and Sturney revisited: the tear chip in cutting interpreted in terms of modern ductile fracture mechanics. Proc I Mech E part C 218:1181–1194

Banks-Sills L, Hershkovitz I, Wawrzynek PA, Eliasi R, Ingraffea AR (2005) Methods for calculating stress intensity factors in anisotropic material: Part I-z = 0 is a symmetric plane. Eng Fract Mech 72:2328–2358

Koch P (1985) Utilization of hardwoods growing on southern pine sites. Agriculture handbook no. 605. U.S. Department of Agriculture, Forest Service, Washington

Kollmann FFP, Cote WA (1984) Principles of wood science and technology, volume I: solid wood. Springer, Berlin

Le-Ngoc L, McCallion H (1997) On the fracture toughness of orthotropic materials. Eng Fract Mech 58:355–362

McKenzie WM (1960) Wood cutting process. For Prod J 10:447–456

McKenzie WM (1962) The relationship between the cutting properties of wood and its physical and mechanical properties. For Prod J 12:287–294

Saouma VE, Sikiotis ES (1986) Stress intensity factors in anisotropic bodies using singular isoparametric elements. Eng Fract Mech 25:115–121

Schachner H, Reiterer A, Stanzl-Tschegg SE (2000) Orthotropic fracture toughness of wood. J Mater Sci Lett 19:1783–1785

Sih GC, Paris PC, Irwin GR (1965) On cracks in rectilinearly anisotropic bodies. Int J Fract Mech 1:189–203

Sitkei G (1983) Fortschritte in der Theorie des Spanens von Holz. Holztechnologie 24:67–70

Stanzl-Tschegg SE, Tan DM, Tschegg EK (1995) New splitting method for wood fracture characterization. Wood Sci Technol 29:31–50

Triboulot P, Asano I, Ohta M (1983) An application of fracture mechanics to the wood-cutting process. Mokuzai Gakkaishi 29:111–117

Williams JG (1998) Friction and plasticity effects in wedge splitting and cutting fracture tests. J Mater Sci 33:5351–5357

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Merhar, M., Bučar, B. Cutting force variability as a consequence of exchangeable cleavage fracture and compressive breakdown of wood tissue. Wood Sci Technol 46, 965–977 (2012). https://doi.org/10.1007/s00226-011-0457-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-011-0457-4