Abstract

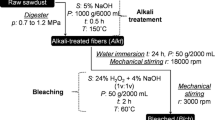

The production of cellulose nanofibrils (CNFs) from Amazonian wood wastes could reduce pollution and raw material costs for cellulose industry. Further studies are required to analyze the feasibility of using hardwood sawdust for the production of high-quality CNF films. Therefore, the objective of this study was to evaluate the impact of various nanofibrillation degrees of waste sawdust generated from the primary processing of different hardwood species on the physical properties of CNF films. Raw sawdust was submitted to alkaline and bleaching pre-treatments. The chemical composition of the bleached fibers was determined. The CNFs were obtained by mechanical shearing of the bleached fibers using a grinder Super MassColloider after 10, 20, 30 and 40 passages. CNFs were evaluated by transmission electron microscopy. The CNF films were formed by the casting method. Residual lignin and hemicelluloses content greatly varied among species after bleaching. No clear influence of the number of passages on apparent density was observed. None of the films was degraded in significant amounts after water immersion. Water vapor absorption (WVA) consistently decreased with more passages through the Super MassColloider for Amazonian species until 30 passages. Residual hemicelluloses of the bleached fibers adversely affected WVA. Bleached fibers made of highly purified cellulose or containing residual lignin showed lower WVA after 30 and 40 passages. Water vapor permeability showed consistent relation with the apparent density of the films. For hardwood wastes, 10–30 passages through the grinder are recommended.

Similar content being viewed by others

References

ABNT (2010a) NBR 14853: determination of soluble matter in ethanol-toluene and in dichloromethane and in acetone. Brazilian Association of Technical Standards, Rio de Janeiro

ABNT (2010b) NBR 7989: pulp and wood—determination of acid-insoluble lignin. Brazilian Association of Technical Standards, Rio de Janeiro

Alila S, Besbesa I, Vilar MR, Mutje P, Boufi S (2013) Nonwoody plants as raw materials for production of microfibrillated cellulose (MFC): a comparative study. Ind Crop Prod 41:250–259

Andresen M, Stenius P (2007) Water-in-oil emulsions stabilized by hydrophobized microfibrillated cellulose. J Dispers Sci Technol 28:837–844

Assis OBG, Silva VL (2003) Water sorption capacity and structural characterization of chitosan thin-films processed from different concentrations. Polim Ciênc Tecnol 13:223–228

ASTM E 104-85 (1991) Standard practice for maintaining constant humidity by means of aqueous solutions. American Society for Testing and Materials, Philadelphia

ASTM E 96-00 (2000) Standard test methods for water vapor transmission of materials. American Society for Testing and Materials, Philadelphia

Avena-Bustillos RJ, Krochta JM (1993) Water vapor permeability of caseinate-based edible films as affected by pH, calcium crosslinking and lipid content. J Food Sci 58:904–907

Azeredo HM, Mattoso LHC, Wood D, Williams TG, Avena-Bustillos RJ, McHugh TH (2009) Nanocomposite edible films from mango puree reinforced with cellulose nanofibers. J Food Sci. doi:10.1111/j.1750-3841.2009.01186.x

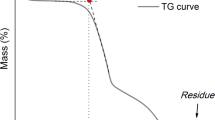

Barneto AG, Vila C, Ariza J (2011) Eucalyptus Kraft pulping production: thermogravimetry monitoring. Thermochim Acta 520:110–120

Batista JA, Tanada-Palmu PS, Grosso CRF (2005) The effect of addition of fatty acids on pectin films. Ciênc Tecnol Aliment 25:781–788

Boran S, Dizman Tomak E, Dönmez Çavdar A (2016) Biological properties of nutshell and microcrystalline cellulose (MCC) filled high density polyethylene composites. Arch Mater Sci Eng 78:71–77

Brodin FW, Gregersen ØW, Syverud K (2014) Cellulose nanofibrils: challenges and possibilities as paper additive or coating material. Nord Pulp Pap Res 29:156–166

Browning BL (1963) The chemistry of wood. Interscience, New York

Bufalino L, Mendes LM, Tonoli GHD et al (2014) New products made with lignocellulosic nanofibers from Brazilian amazon forest. IOP Conf Ser Mater Sci. Eng 64:012012. doi:10.1088/1757-899X/64/1/012012

Bufalino L, Sena Neto AR, Tonoli GHD et al (2015) How the chemical nature of Brazilian hardwoods affects nanofibrillation of cellulose fibers and film optical quality. Cellulose 22:3657–3672

Chaker A, Alila S, Mutjé P, Vilar MR, Boufi S (2013) Key role of the hemicellulose content and the cell morphology on the nanofibrillation effectiveness of cellulose pulps. Cellulose 20:2863–2875

Chen W, Yu H, Liu Y, Chen P, Zhang M, Hai Y (2011a) Individualization of cellulose nanofibers from wood using high-intensity ultrasonication combined with chemical pretreatments. Carbohydr Polym 83:1804–1811

Chen W, Yu H, Li Q, Liu Y, Li J (2011b) Ultralight and highly flexible aerogels with long cellulose I nanofibers. Soft Matter 7:10360–10368

Chun S, Lee S, Doh G, Lee S, Kim JH (2011) Preparation of ultrastrength nanopapers using cellulose nanofibrils. J Ind Eng Chem 17:521–526

Coutts RSP (2005) A review of Australian research into natural fiber cement composites. Cem Concr Compos 27:518–526

Du H, Liu C, Zhang Y, Yu G, Si C, Li B (2016) Preparation and characterization of functional cellulose nanofibrils via formic acid hydrolysis pretreatment and the followed high-pressure homogenization. Ind Crop Prod 94:736–745

Dufresne A (2012) Nanocellulose: from nature to high performance tailored materials. Walter De Gruyter Incorporated, Berlin

Eichhorn SJ, Dufresne A, Arangurem M et al (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33

Fakhouri FM, Fontes LCB, Gonçalves PVM et al (2007) Films and edible coatings based on native starches and gelatin in the conservation and sensory acceptance of Crimson grapes. Ciênc Tecnol Aliment 27:369–375

Fakhouri FM, Martelli SM, Caon T, Velasco JI, Mei LHI (2015) Edible films and coatings based on starch/gelatin: film properties and effect of coatings on quality of refrigerated Red Crimson grapes. Postharvest Biol Technol 109:57–64

Fonseca CS, Silva TF, Silva MF et al (2016) Eucalyptus cellulose micro/nanofibers in extruded fiber-cement composites. Cerne 22:1–9

Fortunati F, Luzia F, Jiménezb A et al (2016) Revalorization of sunflower stalks as novel sources of cellulose nanofibrils and nanocrystals and their effect on wheat gluten bionanocomposite properties. Carbohydr Polym 149:357–368

Garrett TR, Bhakoo M, Zhang Z (2008) Bacterial adhesion and biofilms on surfaces. Prog Nat Sci 18:1049–1056

Gennadios A, Weller CL, Testin RF (1993) Property modification of edible wheat, gluten based films. Trans ASAE 36:465–470

González I, Alcalà M, Chinga-Carrasco G, Vilaseca F, Boufi S, Mutje P (2014) From paper to nanopaper: evolution of mechanical and physical properties. Cellulose 21:2599–2609

Guimarães Júnior M, Botaro VR, Novack KM, Teixeira FG, Tonoli GHD (2015) Starch/PVA-based nanocomposites reinforced with bamboo nanofibrils. Ind Crop Prod 70:72–83

Hassan LM, Mathew AP, Hassan EA, El-Wakil NA, Oksman K (2012) Nanofibers from bagasse and rice straw: process optimization and properties. Wood Sci Technol 46:193–205

Henriksson M, Berglund LA, Isaksson P, Lindström T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromol 9:1579–1585

Ho TT, Zimmermann T, Ohr S, Caseri WR (2012) Composites of cationic nanofibrillated cellulose and layered silicates: water vapor barrier and mechanical properties. Appl Mater Interfaces 4:4832–4840

Ioelovich M (2008) Cellulose as a nanostructured polymer: short review. Bioresour 3:1403–1418

Ioelovich M (2014) Correlation analysis of enzymatic digestibility of plant biomass. Biomass Convers Biorefin 4:269–275

Iwamoto S, Abe K, Yano H (2008) The effect of hemicelluloses on wood pulp nanofibrillation and nanofiber network characteristics. Biomacromol 9:1022–1026

Kennedy F, Phillips GO, Willians PA (1987) Wood and cellulosics, industrial utilization, biotechnology, structure and properties. Ellis Horwood, Chichester

Li Q, Chen W, Li Y et al (2016) Comparative study of the structure, mechanical and thermomechanical properties of cellulose nanopapers with different thickness. Cellulose 23:1375–1382

Lima NN, Mendes LM, Sá VA, Bufalino L (2013) Mechanical and physical properties of LVL panels made from three amazonic species. Cerne 19:407–413

Lopez F (2003) Optimization of hydrogen peroxide in totally chlorine free bleaching of cellulose pulp from olive tree residues. Bioresour Technol 87:255–261

Machado BAS, Nunes IL, Pereira FV, Druzian JI (2012) Development and evaluation of the effectiveness of biodegradable films of cassava starch with nanocellulose as reinforcement and yerba mate extract as an additive antioxidant. Ciênc Rural 42:2085–2091

Marsh K, Bugusu B (2007) Food packaging—roles, materials, and environmental issues. J Food Sci 72:39–55

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994

Nakagaito AN, Yano H (2005) Novel high-strength biocomposites based on microfibrillated cellulose having nanoorder- unit web-like network structure. Appl Phys A 80:155–159

Navarro RMS, Navarro FMS, Tambourgi EB (2007) Study of different processes to obtain the pulp for paper manufacturing. Rev Ciênc Tecnol 1:1–5

Nechyporchuk O, Pignon F, Belgacem MN (2015) Morphological properties of nanofibrillated cellulose produced using wet grinding as an ultimate fibrillation process. J Mater Sci 50:531–541

Nechyporchuk O, Belgacem MN, Bras J (2016a) Production of cellulose nanofibrils: a review of recent advances. Ind Crop Prod 93:2–25

Nechyporchuk O, Belgacem MN, Pignon F (2016b) Current progress in rheology of cellulose nanofibril suspensions. Biomacromol 17:2311–2320

Neutelings G (2011) Lignin variability in plant cell walls: contribution of new models. Plant Sci 181:379–386

Oliveira JTS, Silva JC (2003) Radial variation of shrinkage and specific gravity in Eucalyptus saligna Sm. wood. Rev Árvore 27:381–385

Onoda-Yamamuro N, Yamamuro O, Inamura Y, Nomura H (2007) QENS study on thermal gelation in aqueous solution of methylcellulose. Phys B 393:158–160

Ougiya H, Watanabe K, Morinaga Y, Yoshinaga F (1997) Emulsion-stabilizing effect of bacterial cellulose. Biosci Biotechnol Biochem 61:1541–1545

Panthapulakkal S, Sain M (2013) Isolation of nano fibres from hemp and flax and their thermoplastic composites. Plast Polym Technol 2:9–16

Petroudy SRD, Garmaroody ER, Rudi H (2017) Oriented cellulose nanopaper (OCNP) based on bagasse cellulose nanofibrils. Carbohydr Polym 157:1883–1891

Puangsin B, Fujisawa S, Kuramae R, Saito T, Isogai A (2013) TEMPO-mediated oxidation of hemp bast holocellulose to prepare cellulose nanofibrils dispersed in water. J Polym Environ 21:555–563

Qing Y, Cai Z, Wu Y, Yao C, Wu Q, Li X (2015) Facile preparation of optically transparent and hydrophobic cellulose nanofibril composite films. Ind Crop Prod 77:13–20

Santucci BS, Bras J, Belgacem MN et al (2016) Evaluation of the effects of chemical composition and refining treatments on the properties of nanofibrillated cellulose films from sugarcane bagasse. Ind Crop Prod 91:238–248

Sharma S, Zhang X, Nair SS, Ragauskas A, Zhu J, Deng Y (2014) Thermally enhanced high performance cellulose nano fibril barrier membranes. RSC Adv 4:45136–45142

Siqueira G, Bras J, Dufresne A (2009) Cellulose whiskers versus microfibrils: influence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. Biomacromol 10:425–432

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494

Sobral PJA (2000) Thickness effects of myofibrillar protein based edible films on their functional properties. Pesqui Agropecu Bras 35:1251–1259

Spence KL, Venditti RA, Rojas OJ, Habibi Y, Pawlak JJ (2011) A comparative study of energy consumption and physical properties of microfibrillated cellulose produced by different processing methods. Cellulose 18:1097–1111

Syverud K, Chinga Carrasco G, Toledo J, Toledo PG (2011) A comparative study of Eucalyptus and Pinus radiata pulp fibres as raw materials for production of cellulose nanofibrils. Carbohydr Polym 17:1033–1038

Tammelin T, Harlin A, Vehviläinen M, Nousiainen P, Kolppo K (2011) Method to prepare smooth and even cellulose-lignophenol films. Bioresour 6:2386–2398

Tonoli GHD, Teixeira EM, Correa AC, Marconcini JM, Caixeta LA, Pereira-da-Silva MA, Mattoso LHC (2012) Cellulose micro/nanofibers from Eucalyptus kraft pulp: preparation and properties. Carbohydr Polym 89:80–88

Velásquez-Cock J, Gañán P, Posada P, Castro C, Serpa A, Gomez HC, Putaux J-L, Zuluaga R (2016) Influence of combined mechanical treatments on the morphology and structure of cellulose nanofibrils: thermal and mechanical properties of the resulting films. Ind Crop Prod 85:1–10

Vicentino SL, Floriano PA, Dragunski DC (2011) Films of starch cassava to coat and conservation of grapes. Quim Nova 34:1309–1314

Wang Q, Zhu JY, Considine JM (2013) Strong and optically transparent films prepared using cellulosic solid residue recovered from cellulose nanocrystals production waste stream. Appl Mater Interfaces 5:2527–2534

Zhao J, Zhang W, Zhang X, Lu C, Deng Y (2013) Extraction of cellulose nanofibrils from dry softwood pulp using high shear homogenization. Carbohydr Polym 97:695–702

Zuluaga R, Putaux JL, Cruz J, Vélez J, Mondragon I, Gañán P (2009) Cellulose microfibrils from banana rachis: effect of alkaline treatments on structural and morphological features. Carbohydr Polym 76:51–59

Acknowledgements

The authors are grateful for the financial support provided by Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), Fundação de Amparo à Pesquisa do Estado de Minas Gerais (FAPEMIG) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (Capes).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Scatolino, M.V., Bufalino, L., Mendes, L.M. et al. Impact of nanofibrillation degree of eucalyptus and Amazonian hardwood sawdust on physical properties of cellulose nanofibril films. Wood Sci Technol 51, 1095–1115 (2017). https://doi.org/10.1007/s00226-017-0927-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-017-0927-4