Abstract

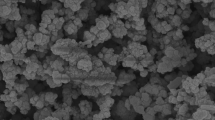

An energy storage system has been designed to study the thermal characteristics of paraffin wax with an embedded nano size copper oxide (CuO) particle. This paper presents studies conducted on phase transition times, heat fraction as well as heat transfer characteristics of paraffin wax as phase change material (PCM) embedded with CuO nanoparticles. 40 nm mean size CuO particles of 2, 5 and 10% by weight were dispersed in PCM for this study. Experiments were performed on a heat exchanger with 1.5–10 l/min of heat transfer fluid (HTF) flow. Time-based variations of the temperature distributions are revealed from the results of observations of melting and solidification curves. The results strongly suggested that the thermal conductivity enhances 6, 6.7 and 7.8% in liquid state and in dynamic viscosity it enhances by 5, 14 and 30% with increasing mass fraction of the CNEPs. The thermal conductivity ratio of the composites can be augmented by a factor up to 1.3. The heat transfer coefficient during solidification increased about 78% for the maximum flow rate. The analysis of experimental results reveals that the addition of copper oxide nanoparticles to the paraffin wax enhances both the conduction and natural convection very effectively in composites and in paraffin wax. The paraffin wax-based composites have great potential for energy storage applications like industrial waste heat recovery, solar thermal applications and solar based dynamic space power generation with optimal fraction of copper oxide nanoparticles.

Similar content being viewed by others

Abbreviations

- A :

-

Cross-sectional area of annulus (m2)

- C :

-

Specific heat of PCM/water (kJ/kg°C)

- CNEP:

-

Copper oxide nanoparticle enhanced phase change material

- CNTs:

-

Carbon nanotubes

- d :

-

Diameter of heat transfer fluid pipe (HTFP) (m)

- Gr :

-

Grashof number, \( \frac{{g\beta \Updelta T\Updelta r_{{m}^{3}} }}{{\nu^{2} }} \) (–)

- HTF:

-

Heat transfer fluid

- H :

-

Latent heat of phase change material (PCM) (kJ/kg)

- h :

-

Heat transfer coefficient (W/m2°C)

- k p :

-

Thermal conductivity of particle material (W/m K)

- k s :

-

Thermal conductivity of phase change material (W/m K)

- k :

-

Thermal conductivity of composite (W/m K)

- l :

-

Length of heat exchanger (m)

- m :

-

Flow rate of heat transfer fluid (HTF) (kg/s)

- M :

-

Mass of PCM (kg)

- Nu :

-

Nusselt number (–)

- Pe :

-

Peclet number, \( \frac{{u \times d_{p} }}{\alpha } \) (–)

- Pr :

-

Prandtl number, \( \frac{{\mu C_{p} }}{k} \) (–)

- Q :

-

Heat value of the PCM during charging or discharging period at any time (kJ)

- Q T :

-

Total heat value of the PCM during charging or discharging period (kJ)

- Q + :

-

Heat fraction

- Ra :

-

Rayleigh number, (Gr * Pr) (–)

- T :

-

Temperature (°C)

- u :

-

Average velocity of cooling water inside the annulus (m/s)

- α :

-

Thermal diffusivity (m2/s)

- μ:

-

Viscosity (kg/m s)

- μ s :

-

Suspension viscosity (kg/m s)

- μ f :

-

Viscosity of base fluid (kg/m s)

- ε:

-

Mass fraction of the CNEPs in the composite

- χ:

-

Wetted perimeter (m)

- ν f :

-

Kinematic viscosity of cooling water (m2/s)

References

Kuznik F, David D, Johannes K, Roux JJ (2011) A review on phase change materials integrated in building walls. Renew Sustain Energy Rev 15(1):379–391

Nomura T, Okinaka N, Akiyama T (2010) Technology of latent heat storage for high temperature applications. A review. Isij Int 50(9):129–139

Ren N, Wu YT, Wang T, Ma CF (2011) Experimental study on optimized composition of mixed carbonate for phase change thermal storage in solar thermal power plant. J Therm Anal Calorim. doi:10.1007/s10973-011-1364-5

Jegadheeswaran S, Pohekar SD (2009) Performance enhancement in latent heat thermal storage system: a review. Renew Sustain Energy Rev 13(9):2225–2244

Sharma A, Tyagi VV, Chen CR, Buddhi D (2009) Review on thermal energy storage with phase change materials and applications. Renew Sustain Energy Rev 13(2):318–345

Luyt AS, Krupa I (2009) Phase change materials formed by uv curable epoxy matrix and Fischer–Tropsch paraffin wax. Energy Convers Manag 50(1):57–61

Zhong YJ, Li SZ, Wei XH, Liu ZJ, Guo QG, Shi JL, Liu L (2010) Heat transfer enhancement of paraffin wax using compressed expanded natural graphite for thermal energy storage. Carbon 48(1):300–304

Sari A (2004) Form-stable paraffin/high density polyethylene composites as solid-liquid phase change material for thermal energy storage: preparation and thermal properties. Energy Convers Manag 45(13–14):2033–2042

Zeng JL, Sun LX, Xu F, Tan ZC, Zhang ZH, Zhang J, Zhang T (2007) Study of a PCM based energy storage system containing Ag nanoparticles. J Therm Anal Calorim 87(2):369–373

Ai DS, Su LZ, Gao Z, Deng CS, Dai XM (2010) Study of ZrO2 nanopowders based stearic acid phase change materials. Particuology 8(4):394–397

Wu SY, Zhu DS, Zhang XR, Huang J (2010) Preparation and melting/freezing characteristics of Cu/paraffin nanofluids as phase-change material (PCM). Energy Fuels 24:1894–1898

Khodadadi JM, Hosseinizadeh SF (2007) Nanoparticle-enhanced phase change material (NEPCM) with great potential for improved thermal energy storage. Int Commun Heat Mass Transf 34(5):534–543

Wu SY, Zhu DS, Li XF, Li H, Lei JX (2009) Thermal energy storage behaviour of Al2O3–H2O nanofluids. Thermochim Acta 483(1–2):73–77

Zeng JL, Cao Z, Yang DW, Xu F, Sun LX, Zhang XF, Zhang L (2009) Effects of MWNTs on phase change enthalpy and thermal conductivity of a solid–liquid organic PCM. J Therm Anal Calorim 95(2):507–512

Siegel R (1977) Solidification of low conductivity material containing dispersed high conductivity particles. Int Heat Mass Transf 20:1087–1089

Chow LC, Zhong JK, Beam JE (1996) Thermal conductivity enhancement for phase change storage media. Int Commun Heat Mass Transf 23:91–100

Min X, Bo F, Kecheng G (2001) Thermal performance of a high conductive shape-established thermal storage material. Sol Energy Mater Sol Cells 69:293–296

Elagfy A, Lafdi K (2005) Effect of carbon nanofibre additives on thermal behaviour of phase change materials. Carbon 43:3067–3074

Wang J, Xie H, Xin Z, Li Y, Chen L (2010) Enhancing thermal conductivity of palmitic acid based phase change materials with carbon nanotubes as fillers. Sol Energy 84:339–344

Wang J, Xie H, Xin Z (2008) Thermal properties of heat storage composites containing multiwalled carbon nanotubes. J Appl Phys 104(11):35–37

Kim S, Drzal LT (2009) High latent heat storage and high thermal conductive phase change materials using exfoliated graphite nanoplatelets. Sol Energy Mater Sol Cells 93:136–142

Coleman HW, Steele WG (1999) Experimentation and uncertainty analysis for engineers, 2nd edn. Wiley, New York

Das SK, Putra N, Thiesen P, Roetzel W (2003) Temperature dependence of thermal conductivity enhancement of nanofluids. J Heat Transf 125:567–574

Chandrasekar M, Suresh S, Chandra Bose A (2010) Experimental investigations and theoretical determination of thermal conductivity and viscosity of Al2O3/water nanofluids. Exp Therm Fluid Sci 34:210–216

Jang SP, Choi SUS (2007) Effects of various parameters on nanofluids thermal conductivity. J Heat Transf 129:617–623

Sari A, Kaygusuz K (2002) Thermal performance of palmitic acid as a phase change energy storage material. Energy Convers Manag 43:863–876

Sari A, Kaygusuz K (2002) Thermal and heat transfer characteristics in a latent heat storage system using lauric acid. Energy Convers Manag 43:2493–2507

Sari A, Kaygusuz K (2001) Thermal performance of myristic acid as a phase change material for energy storage application. Renew Energy 24:303–317

Gorring RL, Churchill SW (1961) Thermal conductivity of heterogeneous materials. Chem Eng Prog 57:53–59

El-Dessouky H, Juwayhel FaisalAl (1997) Effectiveness of a thermal energy storage system using phase change materials. Energy Convers Manag 38(6):601–617

Li Q, Xuan Y (2002) Convective heat transfer and flow characteristics of Cu–water nanofluids. Sci China (Ser E) 45(4):409–416

Brinkman HC (1952) The viscosity of concentrated suspensions and solutions. J Chem Phys 20:1952571–1952581

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jesumathy, S., Udayakumar, M. & Suresh, S. Experimental study of enhanced heat transfer by addition of CuO nanoparticle. Heat Mass Transfer 48, 965–978 (2012). https://doi.org/10.1007/s00231-011-0945-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-011-0945-y