Abstract

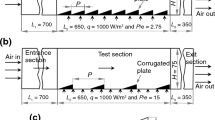

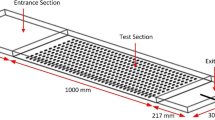

A new design of solar air heater simulator is presented to comply with the extensive applications inagro-industry. A wise installation of increased heat transfer surface area provided uniform and efficient heat diffusion over the duct. Nusselt number and friction factor have been investigated based on the constant roughness parameters such as relative roughness height (e/D), relative roughness pitch (P/e), angle of attack (α) and aspect ratio with Reynolds numbers ranging from 5000 to 19,000 in the fully developed region. Heat fluxes of 800, 900 and 1000 Wm−2 were provided. The enhancement in friction factor is observed to be 3.1656, 3.47 and 3.0856 times, and for the Nusselt number either, augmentation is calculated to be 1.4437, 1.4963 and 1.535 times, respectively, over the smooth duct for 800, 900 and 1000 Wm−2 heat fluxes. Thermohydraulic performance is plotted versus the Reynolds number based on the aforementioned roughness parameters at varying heat fluxes. The results show up that thermohydraulic performance is found to be maximum for 1000 Wm−2 at the average Reynolds number of 5151. Based on the results, we can verify that the introduced solar simulator can help analyzing and developing solar collector installations at the simulated heat fluxes.

Similar content being viewed by others

Abbreviations

- \({\text{A}}_{\text{duct}}\) :

-

Cross sectional area of duct \((A_{duct} = WH)\) (m2)

- \({\text{A}}_{\text{p}}\) :

-

Surface area of collector absorber plate (m2)

- \({\text{c}}_{\text{p}}\) :

-

Specific heat of air at constant pressure (kJ/kg K)

- \({\text{D}}_{\text{h}}\) :

-

Equivalent diameter of the air passage = 2WH/(W + H) (m)

- b:

-

Width of the rib (m)

- e:

-

Roughness height (m)

- e/Dh :

-

Relative roughness height

- P/e:

-

Relative roughness pitch

- d/W:

-

Relative gap position

- f s :

-

Experimental friction factor for smooth duct

- f Blasius :

-

Predicted friction factor for smooth duct by Blasius equation

- f r :

-

Experimental friction factor for roughened duct

- ΔP:

-

Pressure drop through the test section of the absorber plate (Pa)

- Re:

-

Reynolds number

- ρ:

-

Density of air (kg/m3)

- η:

-

Thermohydraulic performance

- ν:

-

Kinematic viscosity (m2/s)

- W:

-

Duct width (m)

- H:

-

Duct height (m)

- α:

-

Angle of attack (°)

- g:

-

Gap width (m)

- d:

-

Center distance of the gap from the side of the duct (m)

- m:

-

Mass flow rate (kg/s)

- Nu:

-

Nusselt number of roughened duct

- Nus :

-

Nusselt number of smooth duct

- Qu :

-

Useful heat gain (Wm−2)

- k:

-

Thermal conductivity of air (W/mK)

- P:

-

Pitch of the rib (m)

- Tf :

-

Bulk mean temperature of the air through the duct (°C)

- Ti :

-

Inlet temperature of the air (°C)

- To :

-

Outlet temperature of the air (°C)

- Tp :

-

Mean temperature of the absorber plate (°C)

- V:

-

Velocity of air (m/s)

- μ:

-

Dynamic viscosity (Pa s)

References

Yadav S, Kaushal M, Varun Siddhartha (2013) Nusselt number and friction factor correlations for solar air heater duct having protrusions as roughness elements on absorber plate. Exp Therm Fluid Sci 44:34–41. doi:10.1016/j.expthermflusci.2012.05.011

Saini JS (2004) Use of artificial roughness for Enhancing Performance of Solar air heater. In: XVII national and VI ISHME/ASME heat and mass transfer conference, India

Saini SK, Saini RP (2008) Development of correlations for Nusselt number and friction factor for solar air heater with roughened duct having arc-shaped wire as artificial roughness. Sol Energy 82(12):1118–1130. doi:10.1016/j.solener.2008.05.010

Jaurker AR, Saini JS, Gandhi BK (2006) Heat transfer and friction characteristics of rectangular solar air heater duct using rib-grooved artificial roughness. Sol Energy 80(8):895–907. doi:10.1016/j.solener.2005.08.006

Nikuradse J (1950) Laws of flow in rough pipes. Committee for Aeronautics Technical Memorandum 1292

Dipprey DF, Sabersky RH (1963) Heat and momentum transfer in smooth and rough tubes at various prandtl numbers. Int J Heat Mass Transf 6(5):329–353. doi:10.1016/0017-9310(63)90097-8

Varun Saini RP, Singal SK (2007) A review on roughness geometry used in solar air heaters. Sol Energy 81(11):1340–1350. doi:10.1016/j.solener.2007.01.017

Han JC (1984) Heat transfer and friction in channels with two opposite rib-roughened walls. J Heat Transf 106(4):774–781. doi:10.1115/1.3246751

Han JC, Park JS, Lei CK (1985) Heat transfer enhancement in channels with turbulence promoters. J Eng Gas Turbines Power 107(3):628–635. doi:10.1115/1.3239782

Aharwal KR, Gandhi BK, Saini JS (2008) Experimental investigation on heat-transfer enhancement due to a gap in an inclined continuous rib arrangement in a rectangular duct of solar air heater. Renew Energy 33(4):585–596. doi:10.1016/j.renene.2007.03.023

Saini RP, Saini JS (1997) Heat transfer and friction factor correlations for artificially roughened ducts with expanded metal mesh as roughness element. Int J Heat Mass Transf 40(4):973–986. doi:10.1016/0017-9310(96)00019-1

Hans VS, Saini RP, Saini JS (2009) Performance of artificially roughened solar air heaters—a review. Renew Sustain Energy Rev 13(8):1854–1869. doi:10.1016/j.rser.2009.01.030

Aharwal KR, Gandhi BK, Saini JS (2009) Heat transfer and friction characteristics of solar air heater ducts having integral inclined discrete ribs on absorber plate. Int J Heat Mass Transf 52(25–26):5970–5977. doi:10.1016/j.ijheatmasstransfer.2009.05.032

Saini RP, Verma J (2008) Heat transfer and friction factor correlations for a duct having dimple-shape artificial roughness for solar air heaters. Energy 33(8):1277–1287. doi:10.1016/j.energy.2008.02.017

ASHRAE Standard 93-2010 (2010) Methods of testing to determine the thermal performance of solar collectors (ANSI approved)

Holman JP (2011) Analysis of experimental data. In: Experimental methods for engineers. McGrawHill, pp 60–165

Gupta D, Solanki SC, Saini JS (1997) Thermohydraulic performance of solar air heaters with roughened absorber plates. Sol Energy 61(1):33–42. doi:10.1016/S0038-092X(97)00005-4

Varun Saini RP, Singal SK (2008) Investigation of thermal performance of solar air heater having roughness elements as a combination of inclined and transverse ribs on the absorber plate. Renew Energy 33(6):1398–1405. doi:10.1016/j.renene.2007.07.013

Acknowledgments

The authors would like to acknowledge the support of Hadi Javidi, Arman Gahremani and Sajjad Baheri in construction and mechanization of this project. Also particular thanks are due to Vice Chancellor of Research and Technology, Urmia University.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Rahmati Aidinlou, H., Nikbakht, A.M. Heat flux: thermohydraulic investigation of solar air heaters used in agro-industrial applications. Heat Mass Transfer 53, 917–928 (2017). https://doi.org/10.1007/s00231-016-1864-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1864-8