Abstract

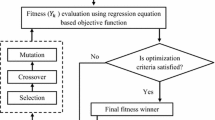

The determination of drying behavior of herbal plants is a complex process. In this study, gene expression programming (GEP) model was used to determine drying behavior of herbal plants as fresh sweet basil, parsley and dill leaves. Time and drying temperatures are input parameters for the estimation of moisture ratio of herbal plants. The results of the GEP model are compared with experimental drying data. The statistical values as mean absolute percentage error, root-mean-squared error and R-square are used to calculate the difference between values predicted by the GEP model and the values actually observed from the experimental study. It was found that the results of the GEP model and experimental study are in moderately well agreement. The results have shown that the GEP model can be considered as an efficient modelling technique for the prediction of moisture ratio of herbal plants.

Similar content being viewed by others

Abbreviations

- e:

-

Experimental value (moisture ratio)

- n:

-

Total number of data

- MR:

-

Moisture ratio, dimensionless

- M:

-

Moisture content (kg moisture/kg dry matter)

- Me :

-

Equilibrium moisture content (kg moisture/kg dry matter)

- M0 :

-

Initial moisture content (kg moisture/kg dry matter)

- MAPE:

-

Mean absolute percentage error

- p:

-

Predicted value (moisture ratio)

- RMSE:

-

Root-mean-squared error

- R2 :

-

R-square

- T:

-

Temperature (°C)

- t:

-

Drying time (min)

- x1, …xn :

-

Relative errors in the individual factors

References

Müller J, Heındl A (2006) Drying of medicinal plants, medicinal and aromatic plants, Chapter 17. Springer, New York, pp 237–252

Rocha RP, Melo EC, Radünz LL (2011) Influence of drying process on the quality of medicinal plants: a review. J Med Plants Res 5(33):7076–7084

Doymaz İ, Tugrul N, Pala M (2006) Drying characteristics of dill and parsley leaves. J Food Eng 77:559–565

Naidu M, Vedashree M, Satapathy P, Khanum H, Ramsamy R, Hebbar HU (2016) Effect of drying methods on the quality characteristics of dill (Anethumgraveolens) greens. Food Chem 192:849–856

Soysal Y, Oztekin S, Eren O (2006) Microwave drying of parsley: modelling, kinetics, and energy aspects. Biosyst Eng 93(4):403–413

Zecchi B, Clavijo L, Garreiro JM, Gerla P (2011) Modeling and minimizing process time of combined convective and vacuum drying of mushrooms and parsley. J Food Eng 104:49–55

Liu X, Chen X, Wu W, Peng G (2007) A neural network for predicting moisture content of grain drying process using genetic algorithm. Food Control 18:928–933

Khazaei NB, Tavakoli T, Ghassemian H, Khoshtaghaza MH, Banakar A (2013) Applied machine vision and artificial neural network for modeling and controlling of the grape drying process. Comput Electron Agric 98:205–213

Erenturk S, Erenturk K (2007) Comparison of genetic algorithm and neural network approaches for the drying process of carrot. J Food Eng 78:905–912

Nadian MH, Rafiee S, Aghbashlo M, Hosseinpour S, Mohtasebi SS (2015) Continuous real-time monitoring and neural network modeling of apple slices color changes during hot air drying. Food Bioprod Process 94:263–274

Karimi F, Rafiee S, Taheri-Garavand A, Karimi M (2012) Optimization of an air drying process for Artemisia absinthium leaves using response surface and artificial neural network models. J Taiwan Inst Chem Eng 43:29–39

Nazghelichi T, Aghbashlo M, Kianmehr MH (2011) Optimization of an artificial neural network topology using coupled response surface methodology and genetic algorithm for fluidized bed drying. Comput Electron Agric 75:84–91

Aktas M, Sevik S, Ozdemir MB, Gonen E (2015) Performance analysis and modeling of a closed-loop heat pump dryer for bay leaves using artificial neural network. Appl Therm Eng 87:714–723

Gül D (2014) The design of vacuum drying oven with heat pumps in order to dry aromatic plants. Master Thesis, Süleyman Demirel University, The Graduate School of Natural and Applied Sciences, Isparta (In Turkish)

Ayaz M (2015) Investigation of drying parameters and drying of medical plants in vacuum heat pump dryer. Master Thesis, Süleyman Demirel University, The Graduate School of Natural and Applied Sciences, Isparta (In Turkish)

Holman JP (1994) Experimental methods for engineers. McGraw-Hill, Singapore

Ferreira C (2006) Gene expression programming: mathematical modeling by an artificial intelligence, 2nd edn. Springer, New York, pp 905–912

Ozbek A, Unsal M, Dikec A (2013) Estimating uniaxial compressive strength of rocks using Genetic Expression Programming. J Rock Mech Geotech Eng 5:325–329

Mousavi SM, Mostafavi ES, Hosseinpour F (2014) Gene expression programming as a basis for new generation of electricity demand prediction models. Comput Ind Eng 74:120–128

Acknowledgements

Authors wish to thank the Süleyman Demirel University Research Foundation (SDUBAP) for the financial support, under Project Numbers: 3447-YL1-13 and 3443-YL1-13.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dikmen, E., Ayaz, M., Gül, D. et al. Gene expression programming approach for the estimation of moisture ratio in herbal plants drying with vacuum heat pump dryer. Heat Mass Transfer 53, 2419–2424 (2017). https://doi.org/10.1007/s00231-017-1998-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-1998-3