Abstract

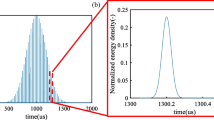

Most previous studies have employed surface patterning to improve the performance of lubrication systems. However, few have experimentally analyzed improved effects on friction reduction in SiC mechanical seals by ultra-fast laser pulse texturing. This work applies surface texturing on a non-contact mechanical seal and analyzes the characteristics of the resultant surface morphology. A femtosecond laser system is employed to fabricate micro/nanostructures on the SiC mechanical seal, and generates microscale-depth stripes and induces nanostructures on the seal surface. This work examines the morphology and cross section of the SiC nanostructures that correspond to the different scanning speeds of the laser pulse. Results show that varying the scanning speed enables the application of nanostructures of different amplitudes and widths on the surface of the seal. The friction coefficient of the introduced SiC full-textured seal is about 20% smaller than that of a conventional SiC mechanical seal. Hence, femtosecond laser texturing is effective and enables direct fabrication of the surface micro/nanostructures of SiC seals. This technique also serves as a potential approach to lubricating applications.

Similar content being viewed by others

References

A. Erdemir, Tribol. Int. 38(3), 249–256 (2005)

I. Etsion, Y. Kligerman, G. Halperin, Tribol. Trans. 42(3), 511–516 (1999)

A. Ronen, I. Etsion, Y. Kligerman, Tribol. Trans. 44(3), 359–366 (2001)

G. Ryk, Y. Kligerman, I. Etsion, Tribol. Trans. 45(4), 444–449 (2002)

R. Rahmani, I. Mirzaee, A. Shirvani, H. Shirvani, Tribol. Int. 43(8), 1551–1565 (2010)

I. Etsion, G. Halperin, Tribol. Trans. 45(3), 430–434 (2002)

I. Etsion, J. Tribol. 127, 248–253 (2005)

V. Brizmer, Y. Zait, Y. Kligerman, I. Etsion, J. Mech. Mater. Struct. 1(5), 865–879 (2006)

I. Etsion, L. Burstein, Tribol. Trans. 39, 667–683 (1996)

B.N. Chichkov, C. Momma, S. Nolte, F. v. Alvensleben, A. Tünnermann, Appl. Phys. A 63(2), 109–115 (1996)

X. Liu, D. Du, G. Mourou, IEEE J. Quantum Electron. 33(10), 1706–1716 (1997)

B.K. Nayak, M.C. Gupta, Opt. Lasers Eng. 48(10), 940–949 (2010)

Z. Guosheng, P. Fauchet, A. Siegman, Phys. Rev. B 26, 5366–5381 (1982)

J. Bonse, H. Sturm, D. Schmidt, W. Kautek, Appl. Phys. A 71(6), 657–665 (2000)

G. Dumitru, V. Romano, H.P. Weber, M. Sentis, W. Marine, Appl. Surf. Sci. 205(1–4), 80–85 (2003)

X.C. Wang, G.C. Lim, F.L. Ng, W. Liu, S.J. Chua, Appl. Surf. Sci. 252, 1492–1497 (2005)

T. Jia, H. Chen, M. Huang, F. Zhao, J. Qiu, R. Li, Z. Xu, X. He, J. Zhang, H. Kuroda, Phys. Rev. B 72, 125429 (2005)

S. Jahanmir, Y. Ozmen, L.K. Ives, Tribol. Lett. 17, 409–417 (2004)

T. Sugita, K. Ueda, Y. Kanemura, Wear 97, 1–8 (1984)

B.S. Phillips, J.S. Zabinski, Tribol. Lett. 17, 533–541 (2004)

Acknowledgements

The authors gratefully appreciate financial support provided by the Industrial Technology Research Institute (ITRI) South, and the Ministry of Economic Affairs (MOEA), Taiwan, R.O.C.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, CY., Chung, CJ., Wu, BH. et al. Microstructure and lubricating property of ultra-fast laser pulse textured silicon carbide seals. Appl. Phys. A 107, 345–350 (2012). https://doi.org/10.1007/s00339-012-6822-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-012-6822-9