Abstract

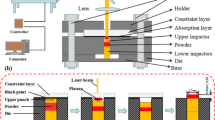

Contact and non-contact techniques are used to obtain monoliths of micro-sized aluminum powder under explosive shock loading. The measurement technique involves instrumented detonics to determine the velocity of detonation and compaction of powder in a single-shot experiment. The compacted specimens were examined for crystallographic, micro-strain, particle size, microstructure, mechanical strength, microhardness and density variations. Results indicate that non-contact technique gives rise to uniform thick compacts with negligible change in particle size, micro-strain, microhardness and microstructure with lower density. Whereas the compacts obtained by contact arrangement are accompanied by a substantial change in these parameters with higher density. Compacts of uniform density greater than 98 % theoretical value have been obtained by using explosive mixture of detonation velocity of 4.2 km/s. The compacted specimens possess micro-strain 2.8×10−3, microhardness (60±2)H v, tensile strength of 112 MPa and compressive strength of 116 MPa with elongation up to 6.4 %. Fracture/void free compacts obtained by contact arrangement have tremendous use in materials science and technology.

Similar content being viewed by others

References

J.R. Davis, Aluminium and Aluminium Alloys (ASM International, 1993)

ASM Handbook, vol. 2 (1990)

N.G. Alba-Baena, W. Salas, L.E. Murr, Mater. Charact. 59, 1152 (2008)

J. Henrych, The Dynamics of Explosion and Its Use (Elsevier Science, New York, 1979)

W. Hermann, D.L. Hicks, E.C. Young, Shock Waves and the Mechanical Properties of Solids (Syracuse University Press, New York, 1971)

K. Shiva Kumar, T. Balakrishna Bhat, P. Ramakrishnan, J. Mater. Process. Technol. 73, 268 (1998)

K. Shiva Kumar, P. Soloman Raj, T. Balakrishna Bhat, K. Hoamoto, J. Mater. Process. Technol. 115, 396 (2001)

D. Raybould, D.G. Morris, G.A. Cooper, J. Mater. Sci. 14, 2523 (1979)

D. Raybould, J. Mater. Sci. 16, 589 (1981)

V.F. Nesterenko, A.V. Muzykantov, Combust. Explos. Shock Waves 21, 730 (1985)

R.J. Patterson, A.R. Cox, E.C. Van Reuth, J. Met. 22, 34 (1980)

G.S. Clyens, W. Jonson, Mater. Sci. Eng. 30, 121 (1977)

N.W. Page, D. Raybould, Mater. Sci. Eng. A 118, 179 (1989)

N.N. Thadhani, A.H. Mutz, T. Vreeland, Acta Metall. 37, 897 (1989)

M.A. Meyers, B. Bhushan Gupta, L.E. Murr, J. Met. 21 (1981)

D.J. Benson, W.L. Nellis, Appl. Phys. Lett. 65, 418 (1994)

M. Zohoor, A. Mehdipoor, J. Mater. Process. Technol. 209, 4201 (2009)

A.D. Sharma, A.K. Sharma, N. Thakur, Philos. Mag. 92, 2108 (2012)

S.S. Bhatsanov, Effects of Explosions on Materials (Springer, New York, 1994)

J.A. Zukas, Explosive Effects and Applications (Elsevier, New York, 1993)

A.A. Bukaemskii, E.N. Fedorova, Combust. Explos. Shock Waves 44, 717 (2008)

D.G. Morris, M.A. Morris, Mater. Sci. Eng. A 104, 201 (1998)

D.G. Morris, Mater. Sci. Eng. 57, 589 (1983)

K.S. Baird, J.D. Williams, Powder Metall. 30, 281 (1987)

Z. Zhao, X.J. Li, T.A.O. Gang, J. Alloys Compd. 478, 237 (2009)

K. Hokamoto, S. Tanaka, M. Fujita, R. Zhang, T. Kodama, T. Awano, Y. Ujimoto, J. Mater. Process. Technol. 85, 153 (1999)

K. Hokamoto, S. Tanaka, M. Fujita, S. Itoh, M.A. Meyers, H.C. Chen, Physica B 239, 1 (1997)

S. Tanaka, K. Hokamoto, M. Fujita, S. Itoh, T. Mashimo, Physica B 239, 16 (1997)

W. Salas, N.G. Alba-Baena, L.E. Murr, Metall. Mater. Trans. A 38, 2928 (2007)

Z. Zhao, X.J. Li, H.H. Yan, D.H. Liu, Combust. Explos. Shock Waves 44, 119–121 (2008)

A.G. Mamalis, G.N. Gioftsidis, A. Szalay, J. Mech. Work. Technol. 19, 239 (1989)

L.E.G. Cambronero, E. Gordo, J.M. Torralba, J.M. Ruiz Prieto, Mater. Sci. Eng. A 207, 36 (1996)

A.G. Mamalis, I.N. Vottea, D.E. Manolakos, J. Mater. Process. Technol. 108, 165 (2001)

M.A. Meyers, Dynamic Behavior of Materials (Wiley, New York, 1994)

B.D. Cullity, Elements of XRD (Addison-Wesley, Reading, 1956)

G.K. Williamson, W.H. Hall, Acta Metall. 1(22), 31 (1953)

B. Morosin, X-Ray Diffraction Line Broadening of Shock-Modified Ceramic Powders (Trans. Tech. Pub., 1987), pp. 285–335

V. Biju, V. Vrinda, S.L. Salini, J. Mater. Sci. 43, 1175 (2008)

M. Hermann, W. Engel, H. Gobel, Advances in X-Ray Analysis (JCPDS, New York, 2002)

K. Sivakumar, K. Hokamoto, J. Mater. Sci. 35, 5823 (2000)

K. Sivakumar, K.S. Prasad, T. Balakrishna Bhat, P. Ramakrishan, J. Mater. Sci. 32, 5271 (1997)

T. Rzychon, K. Rodak, Arch. Mater. Sci. Eng. 28, 605 (2007)

P.C. Lysne, W.J. Halpin, J. Appl. Phys. 39, 5488 (1968)

S.L. Wang, M.A. Meyers, A. Szecket, J. Mater. Sci. 23, 1786 (1988)

M.A. Meyers, D.J. Benson, E.A. Oleveky, Pergamon 47, 2089 (1999)

L.E. Murr, S.M. Tuominen, A.W. Hare, S.H. Wang, Mater. Sci. Eng. 57, 107 (1983)

B.M. Butcher, M.M. Carrol, A.C. Holt, J. Appl. Phys. 45, 3864 (1974)

B.M. Buther, C.N. Karnes, J. Appl. Phys. 40, 2967 (1969)

D.G. Morris, J. Mater. Sci. 21, 1111 (1986)

Acknowledgements

The authors wish to acknowledge the Defence Research and Development Organization (DRDO), India, for Grant-in-aid project No. ERIP/ER/0703665/M/01/1044. Special thanks go to the University Grants Commission (UGC)—New Delhi, India, for providing Research Fellowship No. F.4-1/2006 (BSR)/11-08/2008. Thanks are also due to the Director of TBRL and the entire trial team for necessary assistance in carrying out the experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, A.D., Sharma, A.K. & Thakur, N. Effect of explosive contact and non-contact shock-processing on structure, microstructure and mechanical characteristics of aluminum. Appl. Phys. A 111, 783–789 (2013). https://doi.org/10.1007/s00339-013-7649-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-013-7649-8