Abstract

In this paper, nickel nanoparticles (Ni NPs) were deposited on planar silicon and pyramidal silicon wafers by the magnetron sputtering method, and then these Ni NP-covered samples were etched in a hydrofluoric acid, hydrogen peroxide, and deionized water mixed solution at room temperature to fabricate a low reflective silicon surface. An alumina (Al2O3) film was then deposited on the surface of the as-etched pyramidal sample by atomic layer deposition to further reduce the reflectance. The morphologies and compositions of these samples were studied by using a field emission scanning electron microscope attached to an energy-dispersive X-ray spectrometer. The surface reflectance measurements were carried out with a UV-Vis-NIR spectrophotometer in a wavelength range of 200–1100 nm. The SEM images show that the as-etched planar and pyramidal silicon samples were covered with many rhombic nanostructures and that some nanostructures on the planar silicon surface were ready to exhibit a flower-like burst. The reflectances of the as-etched planar and pyramidal silicon samples were 5.22 % and 3.21 % in the wavelength range of 400–800 nm, respectively. After being coated with a 75-nm-thick Al2O3 film, the etched pyramidal silicon sample showed an even lower reflectance of 2.37 % from 400 nm to 800 nm.

Similar content being viewed by others

References

J. Zhao, A. Wang, M.A. Green, F. Ferrazza, 19.8 % efficient “honeycomb” textured multicrystalline and 24.4 % monocrystalline silicon solar cells. Appl. Phys. Lett. 73, 1991–1993 (1998)

P.K. Singh, R. Kumar, M. Lal, S.N. Singh, B.K. Das, Effectiveness of silicon in aqueous alkaline solutions. Sol. Energy Mater. Sol. Cells 70, 103–113 (2001)

T.-H. Her, R.J. Finlay, C. Eu, S. Deliwala, E. Mazur, Microstructuring of silicon with femtosecond laser pulses. Appl. Phys. Lett. 73, 1673–1675 (1998)

L.L. Ma, Y.C. Zhou, N. Jiang, Wide-band “black silicon” based on porous silicon. Appl. Phys. Lett. 88, 1–3 (2006)

J. Yoo, Reactive ion etching (RIE) technique for application in crystalline silicon solar cells. Sol. Energy 84, 730–734 (2010)

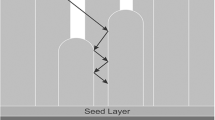

K. Peng, A. Lu, R. Zhang, Motility of metal nanoparticles in silicon and induced anisotropic silicon etching. Adv. Funct. Mater. 18, 3026–3035 (2008)

K. Nishioka, S. Horita, K. Ohdaira, Antireflection subwavelength structure of silicon surface formed by wet process using catalysis of single nano-sized gold particle. Sol. Energy Mater. Sol. Cells 92, 919–922 (2008)

K. Nishioka, T. Sueto, N. Saito, Formation of antireflection nanostructure for silicon solar cells using catalysis of single nano-sized silver particle. Appl. Surf. Sci. 255, 9504–9507 (2009)

Y. Cao, A. Liu, H. Li, Y Liu, F. Qiao, Z. Hu, Y Sang, Fabrication of silicon wafer with ultra low reflectance by chemical etching method. Appl. Surf. Sci. 257, 7411–7414 (2011)

Z. Huang, N. Geyer, P. Werner, J. de Boor, U. Gösele, Metal-assisted chemical etching of silicon: a review. Adv. Mater. 23, 285–308 (2011)

K. Rykaczewski, O.J. Hildreth, C.P. Wong, A.G. Fedorov, J.H.J. Scott, Guided three dimensional catalyst folding during metal-assisted chemical etching of silicon. Nano Lett. 11, 2369–2374 (2011)

C.I. Yeo, Y.M. Song, S.J. Jang, Y.T. Lee, Wafer-scale broadband antireflective silicon fabricated by metal-assisted chemical etching using spin-coating Ag ink. Opt. Express 19, 1109–1116 (2011)

O.J. Hildreth, W. Lin, C.P. Wong, Effect of catalyst shape and etchant composition on etching direction in metal-assisted chemical etching of silicon to fabricate 3D nanostructures. ACS Nano 3, 4033–4042 (2011)

D.H. Lee, Y. Kim, G.S. Doerk, I. Laboriante, R. Maboudian, Strategies for controlling Si nanowire formation during Au-assisted electroless etching. J. Mater. Chem. 21, 10359–10363 (2011)

N. Brahiti, S.-A. Bouanikb, T. Hadjersi, Metal-assisted electroless etching of silicon in aqueous NH4HF2 solution. Appl. Surf. Sci. 258, 5628–5637 (2012)

M.A. Green, Silicon Solar Cells: Advanced Principles and Practice (Bridge, Sydney 1995), pp. 345–356

B.S. Richards, Comparison of TiO2 and other dielectric coatings for buried contact solar cells: a review. Prog. Photovolt. 12, 253–281 (2004)

Acknowledgements

This work is supported by the National Nature Science Foundation of China (61176062), funding from the Jiangsu Innovation Program for Graduate Education (CXLX11_0191) and a project funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yue, Z., Shen, H., Jiang, Y. et al. Novel and low reflective silicon surface fabricated by Ni-assisted electroless etching and coated with atomic layer deposited Al2O3 film. Appl. Phys. A 114, 813–817 (2014). https://doi.org/10.1007/s00339-013-7670-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-013-7670-y