Abstract

Through the equivalence of potential energy and elastic strain energy, a molecular-continuum model combining the concepts of molecular dynamics and continuum mechanics is proposed. Unlike the usual test performed by applying forces, in this model a uniform strain field is employed in the representative volume element of specimens. Through this model, the Young’s moduli, Poisson’s ratios, and shear modulus of graphene sheets and carbon nanotubes (armchair, zigzag, or chiral) can all be written as a simple rational function in which the dependence of radius, chiral angle and thickness can be observed clearly from the explicit closed-form expression. Moreover, according to the proposed molecular-continuum model, an integrated symbolic and numerical computational scheme (ISNC) is established to deal with the general nanoscale elastic solids. Identical results of the closed-form solutions and ISNC verify the correctness of our derivation. Comparison with the results obtained by the other methods or by different potential energy function further justifies the simplicity, validity and efficiency of the proposed model.

Similar content being viewed by others

References

M.M.K. Treacy, T.W. Ebbesen, J.M. Gibson, Nature 381, 678 (1996)

E.W. Wong, P.E. Sheehan, C.M. Lieber, Science 277, 1971 (1997)

A. Krishnan, E. Dujardin, T.W. Ebbesen, P.N. Yianilos, M.M.J. Treacy, Phys. Rev. B 58(20), 14013 (1998)

J.P. Salvetat, G.A.D. Briggs, J.M. Bonard, R.R. Bacsa, A.J. Kulik, Phys. Rev. Lett. 82(5), 944 (1999)

M.F. Yu, B.S. Files, S. Arepalli, R.S. Ruoff, Phys. Rev. Lett. 84(24), 5552 (2000)

D. Sanchez-Portal, A. Emilio, J.M. Soler, Phys. Rev. B 59(19), 12678 (1999)

R. Faccio, P.A. Denis, H. Pardo, C. Goyenola, A.W. Mombru, J. Phys. 21, 285304 (2009)

G. Van Lier, C. Van Alsenoy, V. Van Doren, P. Geerlings, Chem. Phys. Lett. 326, 181 (2000)

V.N. Popov, V.E. Van Doren, Phys. Rev. B 61(4), 3078 (2000)

J.P. Lu, Phys. Rev. Lett. 79(7), 1297 (1997)

C.F. Cornwell, L.T. Wille, Solid State Commun. 101(8), 555 (1997)

Y. Jin, F.G. Yuan, Compos. Sci. Technol. 63, 1507 (2003)

K.M. Liew, X.Q. He, C.H. Wong, Acta Mater. 52, 2521 (2004)

W.X. Bao, C.C. Zhu, C.W. Zhao, Phys. B 352, 156 (2004)

P.M. Agrawal, B.S. Sudalayandi, L.M. Raff, R. Komanduri, Comp. Mater. Sci. 38, 271 (2006)

C. Li, T.W. Chou, Int. J. Solids Struct. 40, 2487 (2003)

C.W. Fan, Y.Y. Liu, C. Hwu, Appl. Phys. A 95, 819 (2009)

P. Zang, Y. Huang, P.H. Geubelle, P.A. Klein, K.C. Hwang, Int. J. Solids Struct. 39, 3893 (2002)

T. Chang, H. Gao, J. Mech. Phys. Solids 51, 1059 (2003)

T. Natsuki, K. Tantrakarn, M. Rndo, Carbon 42, 39 (2004)

J.R. Xiao, B.A. Gama, J.W. GillesPie Jr, Int. J. Solid Struct. 42, 3075 (2005)

T. Chang, J. Geng, X. Guo, Publ. R. Soc A 462, 2523 (2006)

M.M. Shokrieh, R. Rafiee, Mater. Design 31, 790 (2010)

G.M. Odegard, T.S. Gates, L.M. Nicholson, K.E. Wise, Compos. Sci. Technol. 62, 1869 (2002)

Q. Wang, Int. J. Solid Struct. 41, 5451 (2004)

W.D. Cornell, P. Cieplak, C.I. Bayly, I.R. Gould, K.M. Merz Jr, D.M. Ferguson, D.C. Spellmeyer, T. Fox, J.W. Caldwell, P.A. Kollman, J. Am. Chem. Soc. 117, 5179 (1995)

T. Belytschko, S.P. Xiao, G.C. Schatz, R.S. Ruoff, Phys. Rev. B 65, 235430 (2002)

H. Jiang, P. Zhang, B. Liu, Y. Huang, P.H. Geubelle, H. Gao, K.C. Hwang, Comp. Mater. Sci. 28, 429 (2003)

O.L. Blakslee, D.G. Proctor, E.J. Seldin, G.B. Spence, T. Weng, J. Appl. Phys. 41, 3373 (1970)

S.G. Lekhnitskii, Anisotropic plates (Gordon and Breach Science, New York, 1968), pp. 11–14

C. Hwu, Anisotropic elastic plates (Springer, New York, 2010), pp. 7–19

Acknowledgments

The authors would like to thank National Science Council, Taiwan, R.O.C. for support through Grants NSC 97-2923-E-006-001-MY3.

Author information

Authors and Affiliations

Corresponding author

Appendices

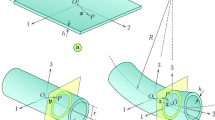

Appendix 1: Atom’s position in the deformed state of uniform strain

1.1 Uniform strain in Cartesian coordinate

Let \( {\mathbf{r^{\prime}}}_{i} = (x^{\prime}_{i} ,y^{\prime}_{i} ,z^{\prime}_{i} ) \) be the position of the ith atom in the deformed state, if the most general uniform strain in Cartesian coordinate is applied we have

where \( u_{i} \), \( v_{i} , \) and \( w_{i} \) denote, respectively, the displacements of the ith atom in x, y, and z directions; \( \varepsilon_{1} ,\varepsilon_{2} ,\varepsilon_{3} \) are the normal strains in x, y, and z directions, whereas \( \varepsilon_{4} ,\varepsilon_{5} ,\varepsilon_{6} \) are the shear strains in yz, xz, and xy planes.

If the material possesses certain symmetric properties or only some of its engineering constants are required to be estimated, to simplify the problem some components of the applied strains may be set to be zero in (52). Following are some special cases which may be encountered in real applications.

-

1.

If only \( E_{i} \) and \( \nu_{ij} \) are required to be estimated, we may set \( \varepsilon_{4} = \varepsilon_{5} = \varepsilon_{6} = 0 \) with \( \varepsilon_{1} , \, \varepsilon_{2} , \, \varepsilon_{3} \ne 0 \).

-

2.

If only \( G_{ij} \) is required, we may set \( \varepsilon_{1} = \varepsilon_{2} = \varepsilon_{3} = 0 \) with \( \varepsilon_{4} , \, \varepsilon_{5} , \, \varepsilon_{6} \ne 0 \)

-

3.

If only in-plane properties are required and only one layer is considered in RVE, we may set \( \sigma_{3} = \sigma_{4} = \sigma_{5} = 0 \), i.e., plane stress condition for thin layer.

Note that if a strain field is considered to be uniform in cylindrical coordinate instead of Cartesian coordinate, the position of the ith atom in the deformed state cannot be expressed by (52) but should be re-derived. In other words, uniform strain fields in cylindrical coordinate may not be uniform in Cartesian coordinate, and vice versa.

1.2 Uniform strain in cylindrical coordinate

In cylindrical coordinate, the strain–displacement relations are

where \( u_{\text{r}} ,u_{\theta } ,u_{z} \) are, respectively, the displacements in radial, circumferential, and axial directions. To find a displacement field corresponding to a uniform strain on the surface of a circular cylinder, suitable integration with respect to \( r,\theta \), and z can be made on (53). With the requirement that \( \varepsilon_{\text{r}} ,\varepsilon_{\theta } ,\varepsilon_{z} ,\varepsilon_{{{\text{r}}\theta }} ,\varepsilon_{\theta z} ,\varepsilon_{{{\text{r}}z}} \) are six arbitrary constants on \( r = R \) where R is the radius of the circular cylinder, a displacement field has been found as follows.

Substituting (54) into the following transformation equation,

the displacement components in x–y–z directions can be obtained as

where

If all the atoms are located on the outer surface of the circular cylinder, we have \( x_{i} = R\cos \theta_{i} = \bar{x}_{i} , \, y_{i} = R\sin \theta_{i} = \bar{y}_{i} \). The position of the ith atom in the deformed state can then be written as

If \( E_{\theta } ,E_{z} \) and \( \nu_{\theta z} \) of a cylindrical anisotropic material (such as CNTs) is considered, we may set \( \varepsilon_{\text{r}} = \varepsilon_{{{\text{r}}\theta }} = \varepsilon_{\theta z} = \varepsilon_{{z{\text{r}}}} = 0 \) with \( \varepsilon_{\theta } ,\varepsilon_{z} \ne 0 \). Note that a homogeneous cylindrical anisotropic material is not homogeneous if the properties are considered in Cartesian coordinate. In other words, \( E_{\theta } ,E_{z} ,\nu_{\theta z} \) are constants for a body with cylindrical anisotropy, their associated elastic constants in Cartesian coordinate such as \( E_{2} ,E_{3} ,\nu_{23} \), etc., are generally not constant but will change from one point of a body to another [30].

Appendix 2: Engineering constants

where \( S_{ij} \) are the elastic compliances. \( E_{1} ,E_{2} ,E_{3} \) are Young’s moduli in \( x_{1} , \, x_{2} \) and \( x_{3} \) directions, respectively; \( \nu_{ij} \) is Poisson’s ratio for transverse strain in the \( x_{j} \)-direction when stressed in the \( x_{i} \)-direction; \( G_{23} ,G_{31} ,G_{12} \) are shear moduli in the \( x_{2} x_{3} \), \( x_{3} x_{1} \) and \( x_{1} x_{2} \) planes, respectively; \( \eta_{i,ij} \) is the coefficient of mutual influence of the first kind which characterizes stretching in the \( x_{i} \)-direction caused by shear in the \( x_{i} x_{j} \)-plane; \( \eta_{ij,i} \) is the coefficient of mutual influence of the second kind which characterizes shearing in the \( x_{i} x_{j} \)-plane caused by a normal stress in the \( x_{i} \)-direction; \( \mu_{ij,kl} \) is the Chentsov coefficient which characterizes the shearing strain in the \( x_{i} x_{j} \)-plane due to shearing stress in the \( x_{k} x_{l} \)-plane.

Although the engineering constants can be obtained from the inverse of the matrix of elastic constants as shown in (58), it is difficult to get the explicit closed-form expressions since the inversion is preformed on a \( 6 \times 6 \) matrix. With this concern, the simplification through the reduction of matrix dimension becomes important. Followings are two examples for the inverse after simplification.

2.1 Orthotropic materials under plane stress condition

If the material to be investigated is orthotropic and the condition of plane stress (\( \sigma_{3} = \sigma_{4} = \sigma_{5} = 0 \)) is assumed, the constitutive relations can be reduced to [31]

where \( \hat{C}_{ij} , \, i,j = 1,2,6 \), are the reduced elastic constants defined by

It has been proved that the reduced elastic constants are related to the elastic compliances by the following inversion,

Note that in this case \( \varepsilon_{3} \) may have non-zero values, and hence the relation (3) with the strain energy density u expressed in terms of \( \varepsilon_{1} ,\varepsilon_{2} ,\varepsilon_{6} \) only should be modified as [31]

2.2 Cylindrical orthotropic materials under plane stress condition

Similar to the reduction shown in (61), if the material to be investigated is cylindrical orthotropic under plane stress condition, the constitutive relations can be written as

Appendix 3: Potential energy functions

3.1 Modified Morse potential function

The modified Morse potential function stated in [21, 27] is

where

3.2 Brenner potential function

The Brenner potential is a multi-body interatomic potential which is usually expressed as [28]

where \( r_{ij} \) is the distance between atom i and atom j, \( U_{\text{R}} \) and \( U_{\text{A}} \) are the repulsive and attractive pair terms given by

The parameters \( D^{{({\text{e}})}} ,S,\beta ,R^{{({\text{e}})}} \) are determined by fitting with known physical properties of carbon and are

The function \( f_{\text{c}} (r) \) is a smooth cut-off function defined by

where

The term \( \bar{B}_{ij} \) in (65) is a multi-body coupling factor defined as

where

and \( \delta = 0.5, \, a_{0} = 0.00020813, \, c_{0} = 330, \, d_{0} = 3.5. \)

Rights and permissions

About this article

Cite this article

Hwu, C., Yeh, YK. Explicit expressions of mechanical properties for graphene sheets and carbon nanotubes via a molecular-continuum model. Appl. Phys. A 116, 125–140 (2014). https://doi.org/10.1007/s00339-014-8241-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-014-8241-6