Abstract

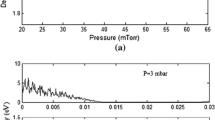

Bismuth thin films have been deposited using pulsed DC magnetron sputter deposition under four deposition conditions, combining powers of 50 and 100 W and argon gas pressures, 2 and 10 mTorr. Estimated deposition rates were between 0.08 and 3.5 nm s−1. The films were examined using scanning electron microscopy, cross-sectioning using a focussed ion beam (FIB), X-ray diffraction and sheet resistance and Hall effect measurement. Room temperature deposition gave a predominant orientational texture of (111) rhombohedral. However, higher film thickness, low sputtering power, high sputtering gas pressure and deposition onto a heated substrate above 125 °C increase the fraction of (110) orientation. FIB cross-sectioning indicates that films deposited at room temperature have an irregular crystalline structure with voids, but those grown at 160 °C are denser with a better polycrystalline structure. Transport measurements indicate a dominance of conduction by electrons, with films deposited at room temperature having high sheet resistance, low sheet resistance being favoured by low sputtering pressure. Deposition at higher temperatures improves the conductivity but increases the Hall coefficient.

Similar content being viewed by others

References

G. Smith, G. Baraff, J. Rowell, Phys. Rev. 135, A1118 (1964)

P. Chiu, I. Shih, Nanotechnology 15, 1489 (2004)

A.A. Ramadan, A.M. El-Shabiny, N.Z. El-Sayed, Thin Solid Films 209, 32 (1992)

M. Inoue, Y. Tamaki, H. Yagi, J. Appl. Phys. 45, 1562 (1974)

L. Kumari, S.-J. Lin, J.-H. Lin, Y.-R. Ma, P.-C. Lee, Y. Liou, Appl. Surf. Sci. 253, 5931 (2007)

Y. Ahn, Y.-H. Kim, S.-I. Kim, K.-H. Jeong, Curr. Appl. Phys. 12, 1518 (2012)

X. Duan, J. Yang, W. Zhu, X. Fan, C. Xiao, Mater. Lett. 61, 4341 (2007)

M. Boffoué, B. Lenoir, A. Jacquot, H. Scherrer, A. Dauscher, M. Stölzer, J. Phys. Chem. Solids 61, 1979 (2000)

J.C.G. de Sande, T. Missana, C.N. Afonso, J. Appl. Phys. 80, 7023 (1996)

J.-H. Hsu, Y.-S. Sun, H.-X. Wang, P.C. Kuo, T.-H. Hsieh, C.-T. Liang, J. Magn. Magn. Mater. 272–276, 1769 (2004)

D.-H. Kim, S.-H. Lee, J.-K. Kim, G.-H. Lee, Appl. Surf. Sci. 252, 3525 (2006)

D. Depla, S. Mahieu, Reactive Sputter Deposition (Springer Science & Business Media, Heidelberg, 2008), p. 590

J. Li, M. K. Narasimhan, V. Pavate, D. Loo, S. Rosenblum, L. Trubell, R. Scholl, S. Seamons, C. Hagerty, and S. Ramaswami, in Microelectron. Manuf., ed. by D.N. Patel and M. Graef (International Society for Optics and Photonics, 1997), pp. 33–41

R.W.G. Wyckoff, Volume 1, 2nd edn. (Wiley, New York, 1963), p. 32

P. Cucka, C.S. Barrett, Acta Crystallogr. 15, 865 (1962)

Powder Diffraction File, Joint Committee on Power Diffraction Standards (ASTM, Philadelphia, PA, 2000). (Card 85-1329)

M. Rudolph, J.J. Heremans, Appl. Phys. Lett. 100, 241601 (2012)

S.A. Stanley, C. Stuttle, A.J. Caruana, M.D. Cropper, A.S.O. Walton, J. Phys. D Appl. Phys. 45, 435304 (2012)

S. Cao, C. Guo, Y. Wang, J. Miao, Z. Zhang, Q. Liu, Solid State Commun. 149, 87 (2009)

B.-K. Wu, H.-Y. Lee, M.-Y. Chern, Appl. Phys. Express 6, 035504 (2013)

Y. Tian, C.F. Guo, S. Guo, Y. Wang, J. Miao, Q. Wang, Q. Liu, AIP Adv. 2, 012112 (2012)

J.A. Thornton, Annu. Rev. Mater. Sci. 7, 239 (1977)

J.A. Thornton, J. Vac. Sci. Technol. 11, 666 (1974)

C.R.M. Grovenor, H.T.G. Hentzell, D.A. Smith, Acta Metall. 32, 773 (1984)

L.J. van der Pauw, Philips Res. Repts. 13, 1 (1958)

Y. Hasegawa, Y. Ishikawa, T. Saso, H. Shirai, H. Morita, T. Komine, H. Nakamura, Phys. B Condens. Matter 382, 140 (2006)

A.H. de Kuijper, J. Bisschop, Thin Solid Films 110, 99 (1983)

C.F. Gallo, B.S. Chandrasekhar, P.H. Sutter, J. Appl. Phys. 34, 144 (1963)

B.Y. Jin, H.K. Wong, G.K. Wong, J.B. Ketterson, Y. Eckstein, Thin Solid Films 110, 29 (1983)

Acknowledgments

John Bates and Geoff West of Loughborough Materials Characterisation Centre are thanked for the SEM and FIB, respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stanley, S.A., Cropper, M.D. Structure and resistivity of bismuth thin films deposited by pulsed DC sputtering. Appl. Phys. A 120, 1461–1468 (2015). https://doi.org/10.1007/s00339-015-9337-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-015-9337-3