Abstract

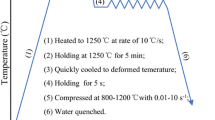

The metadynamic recrystallization (MDRX) behaviors of a typical nickel-based superalloy are investigated by two-pass hot compression tests and four conventional stress-based conventional approaches (offset stress method, back-extrapolation stress method, peak stress method, and mean stress method). It is found that the conventional stress-based methods are not suitable to evaluate the MDRX softening fractions for the studied superalloy. Therefore, a new approach, ‘maximum stress method,’ is proposed to evaluate the MDRX softening fraction. Based on the proposed method, the effects of deformation temperature, strain rate, initial average grain size, and interpass time on MDRX behaviors are discussed in detail. Results show that MDRX softening fraction is sensitive to deformation parameters. The MDRX softening fraction rapidly increases with the increase of deformation temperature, strain rate, and interpass time. The MDRX softening fraction in the coarse-grain material is lower than that in the fine-grain material. Moreover, the observed microstructures indicate that the initial coarse grains can be effectively refined by MDRX. Based on the experimental results, the kinetics equations are established and validated to describe the MDRX behaviors of the studied superalloy.

Similar content being viewed by others

References

M. Hasan Nasab, S. Serajzadeh, Int. J. Adv. Manufact. Technol. 83, 1725 (2016)

M. Seyed Salehi, S. Serajzadeh, Comput. Mater. Sci. 53, 145 (2012)

Y.C. Lin, M.S. Chen, J. Zhong, Comput. Mater. Sci. 44, 316 (2008)

F. Chen, Z.S. Cui, Modell. Simul. Mater. Sci. Eng. 20, 1 (2012)

F. Chen, Z.S. Cui, D.S. Sui, B. Fu, Mater. Sci. Eng., A 540, 46 (2012)

G.Z. Quan, A. Mao, G.C. Luo, J.T. Liang, D.S. Wu, J. Zhou, Mater. Des. 52, 98 (2013)

G.Z. Quan, Y. Wang, Y.Y. Liu, J. Zhou, Mater. Res. 16, 1092 (2013)

X.P. Luo, L. Kang, Q.S. Li, Y.S. Chai, Appl. Phys. A 120, 699 (2015)

D. Xu, B. Zheng, M.Y. Zhu, H.Y. Zhao, Metallurgist. 59, 899 (2016)

L. Meng, M.H. Wang, X. Liu, F.L. Wang, Appl. Phys. A 122, 387 (2016)

Y.C. Lin, L.T. Li, Y.C. Xia, Comput. Mater. Sci. 50, 2038 (2011)

W. Zhang, J. Zhang, Y. Han, R. Liu, D.N. Zou, G.J. Qiao, J. Iron. Steel Res. Int. 23, 151 (2016)

Y.C. Lin, M.S. Chen, Mater. Sci. Eng., A 501, 229 (2009)

K.H. Jung, H.W. Lee, Y.T. Im, Mater. Sci. Eng., A 519, 94 (2009)

L. Cheng, H. Chang, B. Tang, H. Kou, J. Li, Mater. Lett. 92, 430 (2013)

S.H. Cho, K.B. Kang, J.J. Jonas, ISIJ Int. 41, 63 (2001)

A.M. Elwazri, E. Essadiqi, S. Yue, ISIJ Int. 44, 744 (2004)

Y.C. Lin, M.S. Chen, J. Zhong, J. Mater. Process. Technol. 209, 2477 (2009)

H.P. Qi, Y.T. Li, Chinese J. Mech. Eng. 25, 853 (2012)

B. Ma, Y. Peng, Y.F. Liu, B. Jia, J. Cent, South Univ. Technol. 17, 911 (2010)

S.D. Gu, C. Zhang, L.W. Zhang, W.F. Shen, J. Mater. Res. 30, 538 (2015)

B.C. Zhao, T. Zhao, G.Y. Li, Q. Lu, Met. Mater. Int. 21, 692 (2015)

D.X. Wen, Y.C. Lin, J. Chen, J. Deng, X.M. Chen, J.L. Zhang, M. He, Mater. Sci. Eng., A 620, 319 (2015)

Y.C. Lin, D.X. Wen, J. Deng, G. Liu, J. Chen, Mater. Des. 59, 115 (2014)

H. Dehghan, S.M. Abbasi, A. Momeni, A.K. Taheri, Alloys Compd. 564, 13 (2013)

Q. Zuo, F. Liu, L. Wang, C.F. Chen, Z.H. Zhang, Prog. Nat. Sci. 25, 66 (2015)

S.S. Kumar, T. Raghu, P.P. Bhattacharjee, G.A. Rao, U. Borah, J. Mater. Sci. 50, 6444 (2015)

D.X. Wen, Y.C. Lin, H.B. Li, X.M. Chen, J. Deng, Mater. Sci. Eng., A 591, 183 (2014)

Y.Q. Ning, M.W. Fu, X. Chen, Mater. Sci. Eng., A 540, 164 (2012)

H.B. Zhang, K.F. Zhang, S.S. Jiang, Z. Lu, J. Mater. Res. 30, 1029 (2015)

Y.C. Lin, X.Y. Wu, X.M. Chen, J. Chen, D.X. Wen, J.L. Zhang, L.T. Li, J. Alloys Compd. 640, 101 (2015)

X.M. Chen, Y.C. Lin, D.X. Wen, J.L. Zhang, M. He, Mater. Des. 57, 568 (2014)

X.M. Chen, Y.C. Lin, M.S. Chen, H.B. Li, D.X. Wen, J.L. Zhang, M. He, Mater. Des. 77, 41 (2015)

L.A. Reyes, P. Páramo, A.S. Zamarripa, M. de la Garza, M.P. Mata, Mater. Des. 83, 301 (2015)

Y.L. Xu, Q.H. Liu, F. Wang, J. Li, X.S. Xiao, X.L. Cao, Z. Shen, Mater. Des. 65, 840 (2015)

D.G. He, Y.C. Lin, M.S. Chen, J. Chen, D.X. Wen, X.M. Chen, J. Alloys Compd. 649, 1075 (2015)

X.G. You, Y. Tan, J.Y. Li, P.T. Li, C. Dong, S. Shi, J. Liao, S.Q. Qin, J. Alloys Compd. 638, 239 (2015)

Y.C. Lin, J. Deng, Y.Q. Jiang, D.X. Wen, G. Liu, Mater. Sci. Eng., A 598, 251 (2014)

N.Y. Ye, M. Cheng, S.H. Zhang, H.W. Song, H.W. Zhou, P.B. Wang, Int. J. Iron Steel Res. 22, 752 (2015)

S. Antonov, M. Detrois, R.C. Helmink, S. Tin, J. Alloys Compd. 626, 76 (2015)

Z.L. Zhao, Y.Q. Ning, H.Z. Guo, Z.K. Yao, M.W. Fu, Mater. Sci. Eng., A 620, 383 (2014)

A.H. Cottrell, B.A. Bilby, Proc. Phys. Soc. A 62, 49 (1949)

G.T. Hahn, Acta Meta. 10, 727 (1962)

R. Srinivasan, Scr. Metall. Mater. 27, 925 (1992)

G. Li, T.M. Maccagno, D.Q. Bai, J.J. Jonas, ISIJ Int. 36, 1479 (1996)

Y.C. Lin, X.L. Fang, Y.P. Wang, J. Mater. Sci. 43, 5508 (2008)

A.I. Fernández, B. López, J.M. Rodŕiguez–Ibabe, Scr. Mater. 40, 543 (1999)

F. Pilehva, A. Zarei-Hanzaki, S.M. Fatemi-Varzaneh, A.R. Khalesian, J. Mater. Eng. Perform. 24, 1799 (2015)

Y.C. Lin, M.S. Chen, J. Zhong, Mech. Res. Commun. 35, 142 (2008)

M.S. Chen, Y.C. Lin, X.S. Ma, Mater. Sci. Eng., A 556, 260 (2012)

Amir Etaati, Kamran Dehghani, Mater. Chem. Phys. 140, 208 (2013)

C. Roucoules, P.D. Hodgson, S. Yue, J.J. Jonas, Metall. Mater. Trans. A 25, 389 (1994)

Y.S. Na, J.T. Yeom, N.K. Park, J.Y. Lee, J. Mater. Process. Technol. 141, 337 (2003)

Acknowledgments

This work was supported by the National Natural Science Foundation Council of China (Grant No. 51375502), the Project of Innovation-driven Plan in Central South University (No. 2016CX008), the National Key Basic Research Program (Grant No. 2013CB035801), the Natural Science Foundation for Distinguished Young Scholars of Hunan Province (Grant No. 2016 JJ1017), Program of Chang Jiang Scholars of Ministry of Education (No. Q2015140), and Key Laboratory of Safety Design and Reliability Technology for Engineering Vehicle, College of Hunan Province (Grant No. 2016KF1603), China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, Y.C., Chen, XM., Chen, MS. et al. A new method to predict the metadynamic recrystallization behavior in a typical nickel-based superalloy. Appl. Phys. A 122, 601 (2016). https://doi.org/10.1007/s00339-016-0129-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0129-1