Abstract

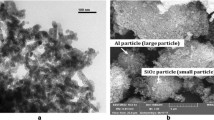

In this article, different aluminum–silicon matrix nano-composites which reinforced by SiO2 nano-particles were developed. The stir casting was used as a solid–liquid phase processing to make such nano-composites. Pouring temperatures and stir times were two parameters which were varied from 700 to 850 °C and 2–4 min, respectively. In addition to microstructural evaluations, the mechanical and tribological properties of different nano-composites were compared to the aluminum alloy without any reinforcement agent. Obtained results showed that the hardness of nano-composites increased significantly when the pouring temperature was 850 °C with respect to the aluminum alloy. The wear resistance was also increased obviously when nano-particles were distributed homogenously in the aluminum matrix. Besides, the ratio of the hardness to the elastic modulus was a compatible parameter to predict the wear rate of most specimens. FESEM images demonstrated that the nano-particles distribution was reasonably uniform. The elastic modulus for all nano-composites increased. The ultimate compressive strength also increased for nano-composites which made at the pouring temperature of 750 °C for both stirring times. The presence of more intermetallic phase especially Al–Ni phase and the micro-cracks were responsible for lowering the toughness of nano-composites which made at higher pouring temperatures.

Similar content being viewed by others

References

K.K. Alaneme, K.O. Sanusi, Microstructural characteristics, mechanical and wear behavior of aluminium matrix hybrid composites reinforced with alumina, rice husk ash and graphite. Eng. Sci. Technol. Int. J. 18, 416–422 (2015)

K. Wang, W. Li, J. Du, P. Tang, J. Chen, Preparation, thermal analysis and mechanical properties of in-situ Al2O3/SiO2(p)/Al composites fabricated by using zircon tailing sand. Mater. Des. 99, 303–313 (2016)

H. Zhu, K. Dong, J. Huang, J. Li, G. Wang, Z. Xie, Reaction mechanism and mechanical properties of an aluminum based composite fabricated in-situ from Al/SiO2 system. Mater. Chem. Phys. 145, 334–341 (2014)

B.N. Sarada, P.L.S. Murthy, G. Ugrasen, Hardness and wear characteristics of hybrid aluminium metal matrix composites produced by stir casting technique. Mater. Today Proc. 2 (2015) 2878–2885

D.K. Koli, G. Agnihotri, R. Purohitc, Influence of ultrasonic assisted stir casting on mechanical properties of Al60 61-nano Al2O3 composites. Mater. Today Proc. 2 (2015) 3017–3026

A. Salehi, S.M. Babakhani, Zebarjad, Microstructural and mechanical properties of Al–SiO2 nano composite foams produced by an ultrasonic technique. Mater. Sci. Eng. A 638, 54–59 (2015)

S. Mt, K.R. Jayadevan, Analysis of stir cast aluminum silicon carbide metal matrix composite: a comprehensive review. Proc. Technol. 24, 379–385 (2016)

S.A. Sajjadi, H.R. Ezatpour, M.T. Parizi, Comparison of microstructure and mechanical properties of A356 aluminum alloy/Al2O3 composites fabricated by stir and compo-casting processes. Mater. Des. 34, 106–111 (2012)

H.R. Ezatpour, S.A. Sajjadi, M.H. Sabzevar, Y. Huang, Investigation of microstructure and mechanical properties of Al6061-nanocomposite fabricated by stir casting. Mater. Des. 55, 921–928 (2014)

M.K. Akbari, H.R. Baharvandi, O. Mirzaee, Nano-sized aluminum oxide reinforced commercial casting A356 alloy matrix: Evaluation of hardness, wear resistance and compressive strength focusing on particle distribution in aluminum matrix. Compos. B 52, 262–268 (2013)

M.K. Akbari, H.R. Baharvandi, O. Mirzaee, Fabrication of nano-sized Al2O3 reinforced casting aluminum composite focusing on preparation process of reinforcement powders and evaluation of its properties. Compos. B 55, 426–432 (2013)

S.A. Sajjadi, H.R. Ezatpour, H. Beygi, Microstructure and mechanical properties of Al–Al2O3 micro and nano composites fabricated by stir casting. Mater. Sci. Eng. A 528, 8765–8771 (2011)

S. Tahamtan, A. Halvaee, M. Emamy, M.S. Zabihi, Fabrication of Al/A206–Al2O3 nano/micro composite by combining ball milling and stir casting technology. Mater. Des. 49, 347–359 (2013)

H.R. Ezatpour, M.T. Parizi, S.A. Sajjadi, Microstructure and mechanical properties of extruded Al/Al2O3 composites fabricated by stir-casting process. Trans. Nonferrous Met. Soc. China 23, 1262–1268 (2013)

I. Dinaharan, Influence of ceramic particulate type on microstructure and tensile strength of aluminum matrix composites produced using friction stir processing. J. Asian Ceram. Soc. 4, 209–218 (2016)

M.H. Jokhio, M.E. Panhwar, M. Aliunar, Manufacturing of aluminum composite material using stir casting process. J. Eng. Technol. 30(1), 53–65 (2011)

V. Balaji, N. Sateesh, M.M. Hussain, Manufacture of aluminium metal matrix composite (Al7075-SiC) by stir casting technique. Mater. Today Proc. 2 (2015) 3403–3408

M.H. Rahman, H.M. Rashed, Characterization of silicon carbide reinforced aluminum matrix composites. Proc. Eng. 90, 103–109 (2014)

S. Mathur, A. Barnawal, Effect of process parameter of stir casting on metal matrix composites. Int. J. Sci. Res. 2, 595–599 (2013)

B. Ravia, B.B. Naik, J.U. Prakash, Characterization of aluminum matrix composites (AA6061/B4C) fabricated by stir casting technique. Mater. Today Proc. 2 (2015) 2984–2990

Q. Hu, H.G. Zhao, J. Ge, Microstructure and mechanical properties of (B4C + Al3Ti)/Al hybrid composites fabricated by a two-step stir casting process. Mater. Sci. Eng. A 650, 478–482 (2016)

K. Wang, W. Lia, J. Dua, L. Yanga, P. Tang, Thermal analysis of in-situ Al2O3/SiO2(p)/Al composites fabricated by stir casting process. Thermochim. Acta 641, 29–38 (2016)

M. Singh, K. Goyal, D.K. Goyal, Fabrication and performance of aluminium based metal matrix composites with SiO2 and TiO2 as reinforced particles. Univers. J. Mech. Eng. 3(4), 142–146 (2015)

M. Okayasu, Y. Ohkura, S. Takeuchi, S. Takasu, H. Ohfuji, T. Shiraishi, A study of the mechanical properties of an Al–Si–Cu alloy (ADC12) produced by various casting processes. Mater. Sci. Eng. A 543, 185–192 (2012)

M. Azadi, M. Zolfaghari, S. Rezanezhad, M. Azadi, Effects of SiO2 nano-particles on tribological and mechanical properties of aluminum matrix composites by different dispersion methods. Appl. Phys. A 124, 377 (2018)

J. Derrien, M. Commandr, J.M. Layet, F. Salvan, A. Cros, Al reaction with SiO2 an auger electron spectroscopy and energy loss spectroscopy study. Appl. Phys. A 28, 247–250 (1982)

A. Salehi, A. Babakhani, S.M. Zebarjad, Investigation of the microstructural and compression properties of Al–SiO2 nanocomposites produced by ultrasound and stir casting. J. Metal. Mater. Eng. 27, 1–2 (2016)

L. Han, Y. Sui, Q. Wang, K. Wang, Y. Jiang, Effects of Nd on microstructure and mechanical properties of cast Al–Si–Cu–Ni–Mg piston alloys. J. Alloy Compd. 695, 1566–1572 (2017)

F. Ansari, A. Sobhani, M. S.Niasari, Simple sol-gel synthesis and characterization of new CoTiO/CoFe O nanocomposite by using liquid glucose, maltose and starch as fuel, capping and reducing agents. J. Colloid Interface Sci. 514, 723–732 (2018)

M. Dadkhah, F. Ansari, M.S. Niasari, Thermal treatment synthesis of SnO2 nanoparticles and investigation of its light harvesting application. Appl. Phys. A 122, 1–9 (2017)

M.K. Akbari, O. Mirzaee, H.R. Baharvandi, Fabrication and study on mechanical properties and fracture behavior of nanometric Al2O3 particle-reinforced A356 composites focusing on the parameters of vortex method. Mater. Des. 46, 199–205 (2013)

S. Neuville, A. Matthews, A perspective on the optimisation of hard carbon and related coatings for engineering applications. Thin Solid Films 515, 6619–6653 (2007)

S. Neuville, Perspective on low energy bethe nuclear fusion reactor with quantum electronic atomic rearrangement of carbon. J. Condens. Matter Nucl. Sci. 22, 1–26 (2017)

M. Mahdiani, A. Sobhani, F. Ansari, M. S.Niasari, Lead hexaferrite nanostructures: green amino acid sol–gel auto combustion synthesis, characterization and considering magnetic property. J. Mater. Sci. Mater. Electron. 28, 17627–17634 (2017)

S. Neuville, Quantum electronic mechanisms of atomic rearrangements during growth of hard carbon films. Surf. Coat. Technol. 206, 703–726 (2011)

S. Sharma, T. Nanda, O.P. Pandey, Effect of particle size on dry sliding wear behavior of sillimanite reinforced aluminium matrix composites. Ceram. Int. 44, 104–114 (2018)

A. Pramanik, Effects of reinforcement on wear resistance of aluminum matrix composites. Trans. Nonferrous Met. Soc. China 26, 348–358 (2016)

M. Azadi, A.S. Rouhaghdam, S. Ahangarani, H.H. Mofidi, Mechanical behavior of TiN/TiC multilayer coatings fabricated by plasma assisted chemical vapor deposition on AISI H13 hot work tool steel. Surf. Coat. Technol. 245, 156–166 (2014)

J.A.K. Gladston, I. Dinaharan, N.M. Sheriff, J.D.R. Selvame, Dry sliding wear behavior of AA6061 aluminum alloy composites reinforced rice husk ash particulates produced using compo-casting. J. Asian Ceram. Soc. 5, 127–135 (2017)

A. Nieto, H. Yang, L. Jiang, J.M. Schoenung, Reinforcement size effects on the abrasive wear of boron carbide reinforced aluminum composites. Wear 390–391 (2017) 228–235

M.I.P. Bahrami, C.A. Canul, N. Gutierrez, Soltani, Wetting and reaction characteristics of crystalline and amorphous SiO2 derived rice-husk ash and SiO2/SiC substrates with Al–Si–Mg alloys. Appl. Surf. Sci. 357, 1104–1113 (2015)

H.E. Dbve, Compressive strength of continuous fiber reinforced aluminium matrix composites. Acta Mater. 45(12), 5041–5046 (1997)

M. Azadi, A.S. Rouhaghdam, Nano-mechanical properties of TiN/TiC multilayer coatings. Strength Mater. 46(1), 121–131 (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mollaei, M., Azadi, M. & Tavakoli, H. A parametric study on mechanical properties of aluminum–silicon/SiO2 nano-composites by a solid–liquid phase processing. Appl. Phys. A 124, 504 (2018). https://doi.org/10.1007/s00339-018-1929-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-1929-2