Abstract

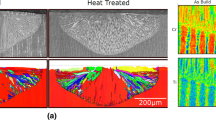

To achieve optimum strengthening effects of external nanoparticles (NPs), uniform dispersion of NPs in the melt is necessary for the casting manufacturing of metal matrix nanocomposites in which dislocation-based strengthening mechanisms play a significant role. However, the engulfment of nanoparticles within the solidifying grains and the avoidance of pushing them outside the solidification front are always a major challenge. Therefore, the understanding of local interface velocity and interface/particle dynamics during alloy solidification is of significant importance. Existing numerical studies on particle engulfment/pushing do not take into consideration the anisotropy of crystal growth and assume planar solidification interface, and thus they are unable to obtain the nanoparticle distribution in realistic alloy solidification. In this research, we investigate the engulfment/push behavior and the overall distribution of SiO2 nanoparticles in the dendrite solidification of an Al–Si binary alloy. Phase-field method is used to simulate the dendrite growth and to predict local solidification front velocity. In combination with the critical engulfment velocity obtained from a non-steady-state particle/front interaction model, the engulfment/push behavior of the entire solidification domain as well as the final distribution of nanoparticles can be analyzed. It is found that the distribution pattern of NPs obtained from simulation is overall consistent with the limited experimental results in the literature. In addition, the two main dislocation-based strengthening effects, e.g., Orowan bowing and CTE (coefficient of thermal expansion) mismatch strengthening, brought by external nanoparticles are quantitatively predicted. The degree of undercooling (60, 80, and 100 K) and nanoparticle size (10, 20, 30, 40, and 50 nm) are varied to investigate their influence on the NP engulfment behavior and the resulted strengthening effects.

Similar content being viewed by others

References

Z. Zhang, D.L. Chen, Mater. Sci. Eng., A 483(148), 152 (2008)

R. Casati, M. Vedani, Metals 4(1), 65–83 (2014)

A. Mazahery, H. Abdizadeh, H.R. Baharvandi, Mater. Sci. Eng., A 518(1), 61–64 (2009)

L.Y. Chen, J.Y. Peng, J.Q. Xu, H. Choi, X.C. Li, Scripta Mater. 69(8), 634–637 (2013)

J.B. Ferguson, B.F. Schultz, P.K. Rohatgi, C.S. Kim, In Light Metals 2014 (Springer, Cham, 2014), pp. 1383–1388

D.R. Uhlmann, B. Chalmers, K.A. Jackson, J. Appl. Phys. 35(10), 2986–2993 (1964)

A.V. Catalina, S. Sen, D.M. Stefanescu, W.F. Kaukler, Metall. Mater. Trans. A 35(5), 1525–1538 (2004)

I.B. Ozsoy, G. Li, H. Choi, H. Zhao, J. Cryst. Growth 422, 62–68 (2015)

J.C. Kao, A.A. Golovin, S. H. Davis 625, 299–320 (2009)

M. Ode, J.S. Lee, S.G. Kim, W.T. Kim, T. Suzuki 40(2), 153–160 (2000)

Y. Yang, J.W. Garvin, H.S. Udaykumar, Int. J. Heat Mass Transf. 51(1–2), 155–168 (2008)

J. Kundin, H. Aufgebauer, C. Reimann, J. Seebeck, J. Friedrich, T. Jauss, A. Croell, Metallurgical and Materials Transactions A 48(1), 342–353 (2017)

A. Dehghan Hamedan, M. Shahmiri, J. Compos. Mater. 51(20), 2913–2932 (2017)

L. Zheng, X. Ma, D. Hu, H. Zhang, T. Zhang, Y. Wan, J. Cryst. Growth 318(1), 313–317 (2011)

J.W. Garvin, Y. Yang, H.S. Udaykumar, Int. J. Heat Mass Transf. 50(15–16), 2952–2968 (2007)

M. Ode, T. Suzuki, S.G. Kim, W.T. Kim, Sci. Technol. Adv. Mater. 1, 1–43 (2000)

K. Wang, H.Y. Jiang, Y.W. Jia, H. Zhou, Q.D. Wang, B. Ye, W.J. Ding, Acta Mater. 103, 252–263 (2016)

L.Y. Chen, J.Q. Xu, H. Choi, H. Konishi, S. Jin, X.C. Li, Nature Communications 5, 3879 (2014)

S. Qiang, Z. Yutuo, C. Haixia, W. Chengzhi, Research and development (2008). Accessed on Feb-28-2019: http://www.foundryworld.com/uploadfile/200922748522189.pdf

S.G. Kim, W.T. Kim, T. Suzuki, Phys. Rev. E 58(3), 3316 (1998)

T. Suzuki, M. Ode, S.G. Kim, W.T. Kim, J. Cryst. Growth 237, 125–131 (2002)

J.L. Murray, A.J. McAlister, The Al–Si (aluminum–silicon) system. Bulletin of Alloy Phase Diagrams 5(1), 74 (1984)

S. Mukherjee, D.M. Stefanescu, Metallurgical and Materials Transactions A 35(2), 613 (2004)

J.Q. Xu, L.Y. Chen, H. Choi, X.C. Li, J. Phys.: Condens. Matter 24(25), 255–304 (2012)

P.C. Hiemenz, R. Rajagopalan, Principles of Colloid and Surface Chemistry, revised and expanded, vol. 14 (CRC Press, Boca Raton, 1997)

H.D. Ackler, R.H. French, Y.M. Chiang, J. Colloid Interface Sci. 179(2), 460–469 (1996)

R.F. Egerton, Electron energy-loss spectroscopy in the electron microscope (Springer, Berlin, 2011)

X.J. Chen, A.C. Levi, E. Tosatti 251, 641–644 (1991)

R.B. Bird, W.E. Stewart, E.N. Lightfoot, Transport Phenomena, Revised 2nd edn. (Wiley, New York, 2007)

D. Shangguan, S. Ahuja, D.M. Stefanescu, Metall. Trans. A 23(2), 669–680 (1992)

D.Y. Chan, R.G. Horn, J Chem Phys 83(10), 5311–5324 (1985)

J. Klein, E. Kumacheva, Science 269(5225), 816–819 (1995)

H. Awaji, Y. Nishimura, S.M. Choi, Y. Takahashi, T. Goto, S. Hashimoto, J. Ceram. Soc. Jpn. 117(1365), 623–629 (2009)

D. Jiang, C. Hong, M. Zhong, M. Alkhayat, A. Weisheit, A. Gasser, R. Poprawe, Surf. Coat. Technol. 249(125), 131 (2014)

N. Hansen, Acta Metall. 25(8), 863–869 (1977)

G.E. Totten, D.S. MacKenzie, Handbook of Aluminum. Physical Metallurgy and Processes, vol. 1 (CRC Press, Boca Raton, 2003)

A.C. Reddy, in National Conference on Advanced Materials and Manufacturing Techniques, March 08-09, 2004, Hyderabad, India (2004)

Q. Zhang, G. Wu, L. Jiang, G. Chen, Mater. Chem. Phys. 82(3), 780–785 (2003)

Z. Zhang, D.L. Chen, Scripta Mater. 54(7), 1321–1326 (2006)

D. Hull, D.J. Bacon, Introduction to Dislocations, 4th edn. (Butterworth-Heinemann, Oxford, 2001)

L. Gong, B. Chen, L. Zhang, Y. Ma, K. Liu, J. Mater. Sci. Technol. 34(5), 811–820 (2018)

K. Glasner, Physica D 151(2–4), 253–270 (2001)

S. Chakraborty, P. Dutta, Int. J. Heat Mass Transf. 46(12), 2115–2134 (2003)

D.M. Herlach, B. Feuerbacher, Adv. Space Res. 11(7), 255–262 (1991)

M.A. Suarez, I. Figueroa, A. Cruz, A. Hernandez, J.F. Chavez, Materials Research 15(5), 763–769 (2012)

Acknowledgements

The authors acknowledge that this work was supported in part by NSF Grant CMMI#1563002.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Shi, J. Engulfment and distribution of second-phase nanoparticle during dendrite solidification of an Al–Si binary alloy: a simulation study. Appl. Phys. A 125, 449 (2019). https://doi.org/10.1007/s00339-019-2738-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-019-2738-y