Abstract.

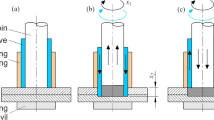

Friction stir welding (FSW) is a relatively new joining technique particularly for aluminum alloys that are difficult to fusion weld. A potential field of application is aircraft structures where cost and weight can be reduced by using new joining techniques instead of riveting. Efforts are currently being made to qualify FSW for this purpose. In this study, the influence of a coolant applied during welding of Al sheets on the residual stress state of the FSW joint was investigated. Liquid CO2 coolant was applied near the weld seam for rapid cooling of the weld zone. The residual stresses across the weld were measured by neutron diffraction. Three sheets were produced, one without cooling, and two with cooling, where two different distances of the coolant nozzles from the FSW tool were chosen. The results show that, by applying a coolant, the magnitude of the tensile stress in the center of the weld can be reduced significantly.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received: 6 July 2001 / Accepted: 13 November 2001

RID="*"

ID="*"Corresponding author. (Fax: +49-4152/87-1338, E-mail: Staron@gkss.de)

Rights and permissions

About this article

Cite this article

Staron, P., Koçak, M. & Williams, S. Residual stresses in friction stir welded Al sheets . Appl Phys A 74 (Suppl 1), s1161–s1162 (2002). https://doi.org/10.1007/s003390201830

Issue Date:

DOI: https://doi.org/10.1007/s003390201830