Abstract

We formed a p–n homojunction by implanting nitrogen ions, serving as a p-type dopant, into an n-type ZnO crystal. A forward bias current was injected into the crystal while irradiating it with light, bringing about Joule heating which annealed the crystal and changed the spatial distribution of the N-dopant concentration. This activated the N-dopant, causing its concentration distribution to be modified in a self-organized manner so as to be suitable for generating dressed photons. A light-emitting diode fabricated by this dressed-photon assisted annealing method showed electroluminescence at room temperature. In a device fabricated by annealing under irradiation with 407 nm-wavelength light, at a forward bias current of 20 mA, the peak wavelength of the electroluminescence was 436 nm, the optical output power was 6.2 μW, and the external quantum efficiency was 1.1×10−4. The emission spectral profile depended on transitions from intermediate phonon states.

Similar content being viewed by others

1 Introduction

ZnO is a direct-transition, wide bandgap semiconductor and is expected to be used as a material for fabricating optical devices such as UV light-emitting diodes and laser diodes [1]. In general, using a semiconductor that can form p–n junctions allows straightforward fabrication of light-emitting diodes and laser diodes [2–5]; however, this is difficult in the case of ZnO. The reason why is that it is difficult to form a p-type crystal because the acceptors are compensated due to the numerous oxygen vacancies and interstitial zinc in the ZnO crystal acting as donors [6]. Therefore, despite the numerous efforts that have been made [7–13], until now there have been very few reports of EL emission at room temperature [11, 12]. Because the radius of N ions is approximately the same as that of oxygen ions, they are promising candidates to serve as p-type dopants in ZnO [1], and N doping by, for example, ion implantation has been examined [14]. However, the large number of lattice defects generated in normal ion implantation cannot be removed even with thermal annealing, and therefore, no p-type crystals of sufficient quality for fabricating devices have been obtained [14].

On the other hand, according to recent research by the authors, the possibility of fabricating p-type ZnO has been increased by employing annealing using dressed photons [15], a technique known as dressed-photon assisted annealing. This annealing method has already been applied to Si, an indirect-transition semiconductor, to realize high-efficiency p–n homojunction-structured LEDs using bulk Si crystal [16]. Also, processing methods based on the same principle have been applied to organic thin-film photovoltaic devices [17], frequency up-conversion via organic dye grains [18], photolithography [19], and subnanometer polishing of glass surfaces [20].

In this study, we successfully fabricated a p–n homojunction-structured LED that emits at room temperature by applying dressed-photon assisted annealing to a bulk ZnO crystal. The principle of the annealing technique, the device fabrication method, and the characteristics of the fabricated devices are described in the following.

2 Principle of dressed-photon assisted annealing

In this study, we used an n-type bulk ZnO crystal implanted with N ions (N dopant) serving as a p-type dopant. In previous work by the authors, when a bulk Si crystal was implanted with boron (B) serving as a p-type dopant, the B was readily activated to form acceptors, thus creating a p–n homojunction [16]; in the present study, however, where we employed ZnO, the N dopant was not readily activated [6]. Therefore, first we tried to activate the N dopant.

Specifically, Joule heating brought about by a forward bias current was used to anneal the crystal, activating the N dopant. An overview of this principle is as follows: if a forward bias current is applied directly after implanting the N dopant, the N is not activated much; therefore, only electrons, which are majority carriers, carry the electrical current. Also, because no holes exist, recombination emission does not take place either. Therefore, the p–n junction remains highly resistive, and when a constant current is applied, the voltage applied across the p–n junction is high. As a result, a high level of Joule heating occurs, diffusing the N dopant and considerably changing the concentration distribution, causing the N dopant to be activated. Therefore, because holes also become current carriers, the resistance decreases. Because ZnO is a direct-bandgap semiconductor, a part of the electrical energy is converted to spontaneous emission optical energy through recombination of electrons and holes, and this is radiated from the crystal. The Joule heating drops due to this energy dissipation and the decrease in resistance mentioned above and, therefore, the concentration distribution of the N dopant eventually reaches a steady state. This completes the N dopant activation process.

Next, we use dressed-photon assisted annealing simultaneously with the activation described above. The process can be explained as follows: a p–n homojunction is formed in the ZnO crystal by implanting N ions; however, because this structure is simple, the electrons and holes both exhibit wide spatial distributions. Therefore, their recombination probability is low, and the emission intensity is also low. The dressed-photon assisted process is used to increase the emission intensity. Specifically, while applying a forward bias current during the annealing, the crystal surface is irradiated with light having a low photon energy compared with the band gap energy. This light is not absorbed in the ZnO crystal and reaches the p–n junction in the form of exciton polaritons. Because the N dopant present in the p–n junction is introduced by ion implantation, its concentration distribution is not homogeneous [21], and centers of localization of electrons and holes are formed at regions of high concentration. Therefore, when these centers of localization are irradiated with the above exciton polaritons, the exciton polaritons are localized. As a result, localized dressed photons are generated in the vicinity of the localized exciton polaritons. These dressed photons can excite multimode coherent phonons in the vicinity of the p–n junction [22], resulting in a state where the dressed photons and phonons are coupled; in other words, dressed-photon phonons are created. On the other hand, because it is difficult to form centers of localization in regions where the N dopant concentration is low, dressed photons and dressed-photon phonons are not created there.

When Joule heating is generated by the forward bias current, the N dopant in the p–n junction is diffused; however, at regions where dressed photons are generated by the process described above, stimulated emission occurs, driven by the dressed photons. Furthermore, in the p–n junction, because an electron population inversion is formed between the conduction band and the valence band, the stimulated emission light produced is amplified by this population inversion. Therefore, part of the electrical energy given by the forward bias current is efficiently converted to the stimulated emission photon energy and is radiated from the crystal. At the same time, spontaneously emitted light is also radiated externally, similar to the case where activation is performed, as described above. Therefore, the amount of thermal energy produced in these regions is small compared with regions where dressed photons are not generated, and thus the N dopants are not easily diffused. As a result, at regions where dressed photons are generated with high efficiency, the concentration distribution of the N dopant hardly changes, maintaining the high dressed-photon generation efficiency.

The electronic transitions related to the above process will now be explained using Fig. 1. A dressed-photon phonon is created by light irradiation, which means that an intermediate state |E g ;el〉⊗|E ex;phonon〉 represented by the direct product of the valence band electronic state |E g ;el〉 and the phonon excited state |E ex;phonon〉 is created. At this time, an electron transitions from the upper state \(| E_{\mathrm{ex}};\mathrm{el} \rangle\otimes|E_{\mathrm{ex}_{\mathrm{thermal}}};\mathrm{phonon} \rangle\), represented by the direct product of the conduction band electronic state |E ex;el〉 and the phonon thermal equilibrium state \(| E_{\mathrm{ex}_{\mathrm{thermal}}};\mathrm{phonon} \rangle\), to the above mentioned intermediate state |E g ;el〉⊗|E ex;phonon〉, and a photon is generated by spontaneous emission (arrow Sp in Fig. 1). Then the electron transitions to the lower state |E g ;el〉⊗|E ex′;phonon〉 represented by the direct product of the valence band electronic state |E g ;el〉 and the phonon low-energy state |E ex′;phonon〉, during which another photon is generated by stimulated emission driven by a dressed photon (arrow St in Fig. 1). As a result, because the concentration distribution of the N dopant is maintained at regions where dressed photons are generated with high efficiency, as described above, Joule-heating annealing and stimulated emission proceed there, eventually forming, in a self-organized manner, a concentration distribution that is suitable for inducing the dressed-photon assisted process with the optimum efficiency. After the annealing, the number of regions with a high efficiency of generating dressed photons is higher than that before the annealing. Hence, considering that the spontaneous emission probability is proportional to the stimulated emission probability, a light-emitting diode that efficiently generates spontaneous emission can be fabricated by using this dressed-photon assisted annealing process.

3 Device fabrication

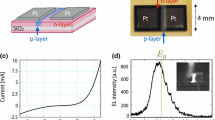

In this study, we used an n-type ZnO single crystal fabricated by the hydrothermal growth method [23]. The crystal axis direction was (0001), the thickness was 500 μm, and the electrical resistivity was 50–150 Ω cm N2+ ions were implanted into the crystal at an energy of 600 keV and an ion dose density of 1.0×1015 cm−2. The implantation depth was confirmed to be about 3 μm by secondary ion mass spectrometry (SIMS). This allowed the N dopant to be distributed in the vicinity of the crystal surface, forming a p-type ZnO layer. As a result, we realized a p–n homojunction structure. Using RF sputtering, a 150 nm-thick indium tin oxide (ITO) film was deposited on the surface of the p-type ZnO layer, and a 5 nm-thick Cr film and a 100 nm-thick Al film were deposited on the surface of the n-type ZnO layer to serve as electrodes. Then, the crystal was diced to form a device with an area of about 9 mm2.

Annealing was performed by causing a forward bias current to flow through the device to generate Joule heating. To do so, the current was made to flow by bringing a W probe into contact with the positive electrode and attaching a Cu film to the negative electrode.

We fabricated the following two types of devices.

- Device 1: :

-

A device fabricated by annealing with a forward bias current alone, without light irradiation, to activate the N dopant.

- Device 2: :

-

A device fabricated by dressed-photon assisted annealing. (To do so, during annealing with the forward bias current, the device was irradiated with laser light having a photon energy hν=3.05 eV (λ=407 nm) lower than the bandgap energy of ZnO (3.4 eV), from the ITO electrode side.)

The forward bias current density for annealing both devices was made as high as possible without causing thermal destruction of the device, namely 0.22 A/cm2. For Device 2, the irradiation power was set as high as possible without causing the crystal temperature to rise, namely, about 1/10 of the input power, or about 2.2 W/cm2. Figure 2(a) shows a thermographic image of the surface of Device 2 about 1 minute after commencing annealing. Figure 2(b) shows the change in surface temperature with time at the center of the device. The surface temperature rose to 100 ∘C when annealing commenced, and then dropped, reaching a constant temperature of 74 ∘C after about 60 minutes. This temperature drop was caused by the generation of dressed photons as annealing progressed, bringing about stimulated emission, and by part of the electrical energy added to produce Joule heating being dissipated in the form of optical energy. To confirm this stimulated emission effect, Fig. 2(c) shows the results of measuring the change in surface temperature with time for another identical sample of Device 2, when the irradiated light power was turned on and off every 5 minutes. The temperature during light irradiation dropped, confirming the stimulated emission effect.

Surface temperature of ZnO crystal annealed while being irradiated with light, showing (a) surface temperature distribution one minute after commencing annealing; (b) change in surface temperature with time at center of crystal surface; and (c) change in surface temperature with time at center of crystal surface when laser irradiation during annealing was turned on and off every 5 minutes

4 Device characterization

Based on the results in Fig. 2(b), we fabricated the two devices described above via dressed-photon assisted annealing for 60 minutes.

First, the characteristics of Device 1 will be described. The three curves in Fig. 3(a) are EL emission spectra of Device 1 at room temperature. These spectra are formed of a high-intensity, narrow-band emission component in the ultraviolet region close to a wavelength of 382 nm and a low-intensity, wide-band emission component in the visible region above 490 nm. The former is attributed to the band edge transition in ZnO, and the latter is attributed to emission from defect levels [24]. The emission from the defect levels is not related to the dressed-photon assisted process in the case of Device 2, described below, and depends on the substrate quality. In other words, from these spectra, the emission from Device 1 was confirmed to be mainly due to the band edge transition. As shown in Fig. 3(b), the I–V characteristic of this device showed the same rectifying properties as an ordinary diode, confirming that a suitable p–n homojunction was formed by the annealing.

Next, the characteristics of Device 2 will be described. EL emission spectra of Device 2 at room temperature are shown by the three curves A, B, and C in Fig. 4(a). Curves A, B, and C show the results obtained with forward bias currents of 10 mA, 15 mA, and 20 mA, respectively. The emission peak wavelength of curve A was 393 nm, which is attributed to the band edge transition, similar to the case of Device 1 (Fig. 3(a)). Comparing curves B and C with curve A, the spectral centroid of the emission spectrum of Device 2 shifted to the long wavelength side as the forward bias current was increased. However, this shift was not attributed to a change in the bandgap energy induced by Joule heating [25], because the emission peak attributed to the band edge transition in Device 1 did not show this kind of shift. Furthermore, as shown in the inset, the emission (arrow C1) attributed to the band edge transition, although weak, was also found in curve C (20 mA). Therefore, we can ignore the long-wavelength shift of the emission spectra attributed to Joule heating at forward bias currents in the range of 10–20 mA. Attributing this long-wavelength shift to stimulated emission driven by dressed photons, not Joule heating, is explained as follows.

Characteristics of Device 2. (a) EL emission spectra, where curves A, B, and C are for forward bias currents of 10, 15, and 20 mA, respectively. Inset is a magnified view of curve C around the photon energy corresponding to the band edge transition. Arrows B 1, B 2, and B 3 show the positions of the peak and two bumps in curve B, respectively. Arrow C 1 in the inset shows the position of a bump in curve C. Arrows C 2 and C 3 show the positions of the peak and a bump in curve C, respectively. (b) Diagram for explaining transitions involving phonons during light emission

A dressed-photon assisted process is involved not only in the device fabrication described in Sect. 3 but also during device operation. Light emission during LED operation, like the stimulated emission process during annealing (Fig. 1), is attributed to a two-step transition, i.e., from \(| E_{\mathrm{ex}};\mathrm{el} \rangle\otimes| E_{\mathrm{ex}_{\mathrm{thermal}}};\mathrm{phonon} \rangle\) to |E g ;el〉⊗|E ex;phonon〉 (the pink arrow at ② in Fig. 4(b)) and from |E g ;el〉⊗|E ex;phonon〉 to |E g ;el〉⊗|E ex′;phonon〉 (the green arrow at ② in Fig. 4(b)). Because the second-step transition is an electric-dipole–forbidden transition, only dressed photons are emitted, and these dressed photons are scattered by the inhomogeneous N dopant concentration and are converted to propagating light. The photon energy of the emitted dressed photons is determined by the photon energy of the light radiated during annealing (3.05 eV, wavelength 407 nm). This is because the N dopant concentration distribution is formed in a self-organized manner by the dressed-photon assisted annealing described in Sect. 3, with the result that, in Device 2, a transition via the intermediate phonon level corresponding to the photon energy of the irradiation light easily occurs. Therefore, in curve B in Fig. 4(a), the peak photon energy of 3.03 eV (409 nm; arrow B1) is the same as the photon energy of the irradiation light.

On the other hand, the photon energy of light generated in the first-step transition is given by the energy difference between \(|E_{\mathrm{ex}};\mathrm{el} \rangle\otimes| E_{\mathrm{ex}_{\mathrm{thermal}}};\mathrm{phonon} \rangle\) and |E g ;el〉⊗|E ex;phonon〉. Comparing the blue arrow at ① in Fig. 4(b) and the green arrow at ② in Fig. 4(b), this photon energy is 0.20 eV. (The blue arrow at ① represents the band edge transition of ZnO, whose energy is 3.25 eV (382 nm) according to Fig. 3(a).) This first-step transition is an electric-dipole-allowed transition; however, because the occupation probability of such high-energy phonons is low, propagating light is not emitted, and only dressed photons, which can couple with multimode coherent phonons, are generated. In addition, when the stimulated emission driven by the dressed photons emitted in the first-step transition is repeated one more time and two more times, new intermediate phonon levels |E g ;el〉⊗|E ex″;phonon〉 (③ in Fig. 4(b)) and |E g ;el〉⊗|E ex‴;phonon〉 (④ in Fig. 4(b)) are formed whose eigenenergies are lower by amounts corresponding to an integer multiple of the photon energy of the dressed photons. Thus, the energies of the photons emitted via these new intermediate phonon levels are lower by amounts corresponding to the energy of the dressed photons emitted in the first-step transition (0.20 eV). In the case of ③ and ④, these photon energies are 2.85 eV (435 nm) and 2.65 eV (468 nm), respectively, as shown by the yellow arrow and the red arrow in Fig. 4(b). These are similar to the emission peaks measured in the conventional optical transition of bulk ZnO crystal, which are an integer multiple of the LO phonon energy (72 meV) [24]. However, unlike the conventional optical transition, in the transition driven by dressed photons, the energy that is exchanged is an integer multiple of the energy determined by dressed-photon phonons among the multiple phonon modes involved, rather than a material-specific phonon mode. The slope of curve B (forward bias current of 15 mA) shows two bumps (arrows B2 and B3 in curve B), whose positions were found to be 2.84 eV (436 nm) and 2.64 eV (470 nm), respectively, by the curve fitting based on the second-derivative spectroscopy method [26]. These agree well with the photon energies indicated by the yellow and red arrows at ③ and ④ in Fig. 4(b). In addition, curve C (20 mA) also shows a peak (arrow C2) and one bump (arrow C3) at 2.84 eV (436 nm) and 2.63 eV (471 nm), respectively. These also agree well with the photon energies indicated by the yellow and red arrows at ③ and ④ in Fig. 4(b).

Light emission via the intermediate phonon levels occurs not only due to single- or two-step stimulated emission at ③ and ④ in Fig. 4(b) but also due to multistep stimulated emission, therefore, when the forward bias current is increased, the emission intensity at the low-energy side also increases, which explains the long-wavelength shift in Fig. 4(a). Note that the emission intensity due to the band gap transition in curve B is small; this is attributed to the fact that the transition ① involving stimulated emission is faster than the transition ② involving only spontaneous emission, because electrons in the conduction band for stimulated emission relax to the intermediate phonon level.

To compare the performance of Devices 1 and 2, curves A and B in Fig. 5 respectively show how the optical output power of the two devices depended on the forward bias current. The optical output power was obtained by integrating the curves A, B, and C in Fig. 4 in the wavelength range 350–600 nm. For curve B, at the forward bias current of 20 mA (current density 0.22 A/cm2), the optical output power from Device 2 was 6.2 μW, which was about 15 times higher than the optical output power from Device 1, shown in curve A. The external quantum efficiency was 1.1×10−4.

From the above results, we showed that dressed-photon assisted annealing, which has been used for fabricating indirect-bandgap semiconductor optical devices, is effective even for direct-transition semiconductors. At present, the maximum forward bias current that can be injected is determined by the thermal destruction limit of the device. Therefore, it should be possible to achieve further increases in the optical output power and emission efficiency by improving the electrical and thermal properties of the bulk ZnO crystals to be used.

5 Conclusion

We succeeded in fabricating a light-emitting diode having a p–n homojunction structure by applying dressed-photon assisted annealing to an n-type ZnO crystal doped with N ions by ion implantation. The device showed good EL emission characteristics at room temperature. Specifically, annealing was achieved by Joule heating alone, without irradiating the device with light, activating the N dopant. The emission peak wavelength of the fabricated device was 382 nm. As for the device fabricated by dressed-photon assisted annealing while radiating light, the emission peak wavelength at a forward bias current of 20 mA was 436 nm, the optical output power was 6.2 μW, and the external quantum efficiency was 1.1×10−4. The emission spectral profile was found to be dependent on transitions from intermediate phonon states.

References

Y.-S. Choi, J.-W. Kang, D.-K. Hwang, S.-J. Park, IEEE Trans. Electron Devices 57, 26 (2010)

T.M. Quist, R.H. Rediker, R.J. Keyes, W.E. Krag, B. Lax, A.L. McWhorter, H.J. Ziergler, Appl. Phys. Lett. 1, 91 (1962)

N. Holonyak, S.F. Bevacqua, Appl. Phys. Lett. 1, 82 (1962)

R.N. Hall, G.E. Fenner, J.D. Kingsley, T.J. Soltys, R.O. Carlson, Phys. Rev. Lett. 9, 366 (1962)

M.I. Nathan, W.P. Dumke, G. Burns, F.H. Dill, G. Lasher, Appl. Phys. Lett. 1, 62 (1962)

D. Seghier, H.P. Gislason, J. Mater. Sci., Mater. Electron. 19, 687 (2008)

A. Tsukazaki, A. Ohtomo, T. Onuma, M. Ohtani, T. Makino, M. Sumiya, K. Ohtani, S.F. Chichibu, S. Fuku, Y. Segawa, H. Ohno, H. Koinuma, M. Kawasaki, Nat. Mater. 4, 42 (2005)

A. Tsukazaki, M. Kubota, A. Ohtomo, T. Onuma, K. Ohtani, H. Ohno, S.F. Chichibu, M. Kawasaki, Jpn. J. Appl. Phys. 44, L643 (2005)

W.Z. Xu, Z.Z. Ye, Y.J. Zeng, L.P. Zhu, B.H. Zhao, L. Jiang, J.G. Lu, H.P. He, S.B. Zhang, Appl. Phys. Lett. 88, 173506 (2006)

Z.P. Wei, Y.M. Lu, D.Z. Shen, Z.Z. Zhang, B. Yao, B.H. Li, J.Y. Zhang, D.X. Zhao, X.W. Fan, Z.K. Tang, Appl. Phys. Lett. 90, 042113 (2007)

J. Kong, S. Chu, M. Olmedo, L. Li, Z. Yang, J. Liu, Appl. Phys. Lett. 93, 132113 (2008)

A. Nakagawa, T. Abe, S. Chiba, H. Endo, M. Meguro, Y. Kashiwaba, T. Ojima, K. Aota, I. Niikura, Y. Kashiwaba, T. Fujiwara, Phys. Status Solidi C 6, S119 (2009)

F. Sun, C.X. Shan, B.H. Li, Z.Z. Zhang, D.Z. Shen, Z.Y. Zhang, D. Fan, Opt. Lett. 36, 499 (2011)

Z.Q. Chen, T. Sekiguchi, X.L. Yuan, M. Maekawa, A. Kawasuso, J. Phys., Condens. Matter 16, S293 (2004)

T. Kawazoe, K. Kobayashi, S. Takubo, M. Ohtsui, J. Chem. Phys. 122, 024715 (2005)

T. Kawazoe, M.A. Mueed, M. Ohtsu, Appl. Phys. B 104, 747 (2011)

S. Yukutake, T. Kawazoe, T. Yatsui, W. Nomura, K. Kitamura, M. Ohtsu, Appl. Phys. B 99, 415 (2010)

T. Kawazoe, H. Fujiwara, K. Kobayashi, M. Ohtsu, IEEE J. Sel. Top. Quantum Electron. 15, 1380 (2009)

T. Kawazoe, M. Ohtsui, Y. Inao, R. Kuroda, J. Nanophotonics 1, 011595 (2007)

T. Yatsui, K. Hirata, W. Nomura, Y. Tabata, M. Ohtsu, Appl. Phys. B 93, 55 (2008)

W.L. Ng, M.A. Lourenco, R.M. Gwilliam, S. Ledain, G. Shao, K.P. Homewood, Nature 410, 192 (2001)

Y. Tanaka, K. Kobayashi, Physica E 40, 297 (2007)

T. Sekiguchi, S. Miyashita, K. Obara, T. Shishido, N. Sakagami, J. Cryst. Growth 214/215, 72 (2000)

Ü. Özgür, Y.I. Alivov, C. Liu, A. Teke, M.A. Reshchikov, S. Doğan, V. Avrutin, S.-J. Cho, H. Morkoç, J. Appl. Phys. 98, 041301 (2005)

M.S. Kim, K.G. Yim, J.Y. Leem, D.Y. Lee, J.S. Kim, J.S. Kim, J. Korean Phys. Soc. 58, 821 (2011)

H. Mach, C.R. Middaugh, Anal. Biochem. 222, 323 (1994)

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Kitamura, K., Kawazoe, T. & Ohtsu, M. Homojunction-structured ZnO light-emitting diodes fabricated by dressed-photon assisted annealing. Appl. Phys. B 107, 293–299 (2012). https://doi.org/10.1007/s00340-012-4991-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-012-4991-z