Abstract

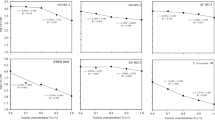

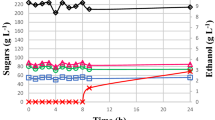

Molasses “B” is a rich co-product of the sugarcane process. It is obtained from the second step of crystallization and is richer in fermentable sugars (50–65%) than the final molasses, with a lower non-sugar solid content (18–33%); this co-product also contains good vitamin and mineral levels. The use of molasses “B” for ethanol production could be a good option for the sugarcane industry when cane sugar prices diminish in the market. In a complex medium like molasses, osmotolerance is a desirable characteristic for ethanol producing strains. The aim of this work was to evaluate the use of molasses “B” for ethanol production using Saccharomyces cerevisiae ITV-01 (a wild-type yeast isolated from sugarcane molasses) using different initial sugar concentrations (70–291 g L−1), two inoculum sizes and the addition of nutrients such as yeast extract, urea, and ammonium sulphate to the culture medium. The results obtained showed that the strain was able to grow at 291 g L−1 total sugars in molasses “B” medium; the addition of nutrients to the culture medium did not produce a statistically significant difference. This yeast exhibits high osmotolerance in this medium, producing high ethanol yields (0.41 g g−1). The best conditions for ethanol production were 220 g L−1 initial total sugars in molasses “B” medium, pH 5.5, using an inoculum size of 6 × 106 cell mL−1; ethanol production was 85 g L−1, productivity 3.8 g L−1 h−1 with 90% preserved cell viability.

Similar content being viewed by others

Abbreviations

- μ max :

-

Maximum specific growth rate (h−1)

- Y x/s :

-

Biomass yield (g biomass g−1 substrate)

- Y et/s :

-

Ethanol yield (g ethanol g−1 substrate)

- Y et/x :

-

Ethanol specific yield (g ethanol g−1 biomass)

- P et :

-

Ethanol productivity (g ethanol L−1 h−1)

- %V :

-

Cell viability (%)

References

Berg C (2004) World fuel ethanol analysis and outlook. Short communication, F.O. Licht

Sánchez OJ, Cardona CA (2008) Trends in Biotechnological production of fuel ethanol from different feedstocks. Bioresour Technol 99:5270–5295

Balat M, Balat H (2009) Recent trends in global production and utilization of bio-ethanol fuel. Appl Energy 86:2273–2282

Cardona CA, Sanchez OJ (2007) Fuel ethanol production: process design trends and integration opportunities. Bioresour Technol 98:2415–2457

Ergun M, Ferda MS (2000) Application of a statistical technique to the production of ethanol from sugar beet molasses by Saccharomyces cerevisiae. Bioresour Technol 73:251–255

Pramanik K, Rao DE (2005) Kinetic Study on Ethanol Fermentation of Grape Waste using Saccharomyces cerevisiae yeast isolated from toddy. Inst Eng Indian J 85:53–58

Rhonda H, Winston AM (1989) Malt hydrolysis of sweet-potatoes and eddoes for ethanol production. Biol Wastes 29:263–270

Kilpimaa S, Kuokkanen T, Lassi U (2009) Bio-ethanol production from waste potatoes. In: Paukkeri A, Ylä-Mella J, Pongrácz E (eds) Energy research at the University of Oulu. Proceedings of the EnePro conference, June 3rd, 2009, University of Oulu, Finland pp 21–23

Doran JB, Aldrich HC, Ingram LO (1994) Saccharification and fermentation of sugarcane bagasse by Klebsiella oxytoca P2 containing chromosomally integrated genes encoding the Zymomonas mobilis ethanol pathway. Biotechnol Bioeng 44:240–247

Bertolini MC, Ernandes JR, Laluce C (1991) New yeast strains for alcoholic fermentation at high sugar concentration. Biotechnol Lett 3:197–202

Asghari A, Bothast RJ, Doram JB, Ingram LO (1996) Ethanol production from hemicellulosic hydrolysates of agricultural residues using genetically engineered Escherichia coli strain KO11. J Ind Microbiol 16:42–47

Alkasrawi M, Andreas R, Gunnar L, Guido Z (2006) Influence of strain and cultivation procedure on the performance of simultaneous saccharification and fermentation of steam pretreated spruce. Enzyme Microb Technol 38:279–286

Enriquez-Poy M (2005) Producción de etanol anhidro en los ingenios azucareros. Short communication, CONAE. México

Unión Nacional de Cañeros AC (2011) CNPR. Boletín de Prensa Mar 007

Da Silva GP, de Araújo E, Daison OS, Guimaraes WV (2005) Ethanolic fermentation of sucrose, sugar cane juice and molasses by Escherichia coli K011 y Klebsiella Oxytoca P2. Braz J Microbiol 36:395–404

Ortiz-Zamora O, Cortés-García R, Ramírez-Lepe M, Gómez-Rodríguez J, Aguilar-Uscanga MG (2009) Isolation and selection of ethanol-resistant and osmotolerant yeasts from regional agricultural sources in Mexico. J Food Process Eng 32:775–786

Campos-Pastelín JM (2008) Establecimiento de un proceso de producción de Etanol a partir de Jugo de caña y miel intermedia “B” con Saccharomyces cerevisiae ITV-01 y S. cerevisiae EDV-493. Masters Thesis, Instituto Unidad de Investigación y Desarrollo de Alimentos, Tecnológico de Veracruz-México

Ortiz-Muñiz B, Carvajal-Zarrabal O, Torrestiana-Sanchez B, Aguilar-Uscanga MG (2010) Kinetic study on ethanol production using Saccharomyces cerevisiae ITV-01 yeast isolated from sugar cane molasses. J Chem Technol Biotechnol 85:1361–1367

Moulin G, Boze H, Galzy P (1984) Inhibition of alcoholic fermentation. Biotechnol Gen Eng Rev 2:365–382

Jones SRP, Pammen TN, Greenfirled PF (1981) Alcohol fermentation by yeast: the effect of environmental and other variables. Process Biochem 16:42–45

Walker GM (1998) Yeast physiology and biotechnology. Wiley, Chichester

Shen B, Hohman S, Jensen RG, Bohnert H (1999) Roles of sugar alcohols in osmotic stress adaptation. Replacement of glycerol by mannitol and sorbitol in yeast. Plant Physiol 21:42–52

Schhüller C, Brewster JL, Alexander MR, Gustin MC, Ruis H (1994) The HOG pathway controls osmotic regulation of transcription via the stress response element (STRE) of Saccharomyces cerevisiae CTTI gene. EMBO J 13:4382–4389

Myers DK, Lawlor DTM, Attfield PV (1997) Influence of invertase activity and glycerol synthesis and retention on fermentation of media with a high sugar concentration by Saccharomyces cerevisiae. Appl Environ Microbiol 63:145–150

Lange H, Bavouzet JM, Taillander P, Delorme C (1993) Systematic error and comparison of four methods for assessing the viability of Saccharomyces cerevisiae suspensions. Biotechnol Tech 7:223–228

Imai T, Ohno T (1995) The relationship between viability and intracellular pH in the yeast Saccharomyces cerevisiae. Appl Environ Microbiol 61(10):3604–3608

Gilis JF (1999) Etude de Contaminations de Fermentations Alcooliques Industrielles par les Levures Brettanomyces. Doctoral Thesis. Institut National Polytechnique de Toulouse, France

Salmon JM (1989) Effect of sugar transport inactivation in Saccharomyces cerevisiae on sluggish and stuck enological fermentations. Appl Environ Microbiol 55:953–958

Léao C, Van Uden N (1982) Effects of ethanol and other alkanols on the glucose transport system of Saccharomyces cerevisiae. Biotechnol Bioeng 24:2601–2604

Berthels NJ, Cordero-Otero RR, Bauer FF, Thevelein JM, Pretorius IS (2004) Discrepancy in glucose and fructose utilization during fermentation by Saccharomyces cerevisiae wine yeast strains. FEMS Yeast Res 4:683–689

Albers E, Larsson C, Liden G, Niklasson C, Gustafsson L (1996) Influence of the nitrogen source on Saccharomyces cervisiae anaerobic growth and product formation. Appl Environ Microbiol 62:3187–3195

Mendes-Ferreira A, Mendes-Faia A, Léao C (2004) Growth and fermentation patterns of Saccharomyces cerevisiae under different ammonium concentrations and its implications in winemaking industry. J Appl Microbiol 97:540–545

Erten H, Tanguler H, Cabaroglu T, Canbas A (2006) The influence of inoculum level on fermentation and flavour compounds of white wines made from cv. Emir. J Inst Brew 112(3):232–236

Mateo JJ, Jiménez M, Pastor A, Huerta T (2001) Yeast starter cultures affecting wine fermentation and volatiles. Food Res Int 34(4):307–314

Letourneau F, Villa P (1987) Saccharomyces yeast growth on beet molasses. Effects of substrate concentration on alcohol toxicity. Biotechnol Lett 9(1):53–58

De Miniac M (1991) Utilisation des levures en fermentation alcoolique industrielle in Biotechnologie des levures. Doctoral Thesis, Paris, France pp 335–370

Hohmann S (2002) Osmotic stress signaling and osmosadaptation in yeasts. Microbiol Mol Biol Rev 66:300–372

Alfenore S, Cameleyre X, Benbadis L, Bideaux C, Uribelarrea J-L, Goma G, Molina-Jouve C, Guillouet SE (2004) Aeration strategy: a need for very high ethanol performance in Saccharomyces cerevisiae fed-batch process. Appl Microbiol Biotechnol 63:537–542

Acknowledgments

Authors acknowledge the National Council of Science and Technology (CONACYT) for financial support (scholarship number 8765 and project No128052 FOMIX-CONACYT) and also the critical reading of the text by Patricia M. Hayward Jones MSc. and Dulce María Barradas Dermitz MSc.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fernández-López, C.L., Torrestiana-Sánchez, B., Salgado-Cervantes, M.A. et al. Use of sugarcane molasses “B” as an alternative for ethanol production with wild-type yeast Saccharomyces cerevisiae ITV-01 at high sugar concentrations. Bioprocess Biosyst Eng 35, 605–614 (2012). https://doi.org/10.1007/s00449-011-0633-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-011-0633-9