Abstract

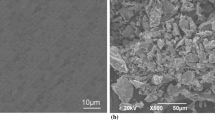

Because it is difficult to adapt ceramic technology to prevent ceramic fractures, attention has been directed at the development of a new metal alloy, the surface of which can be treated to be made more scratch-resistant than cobalt chromium alloy. A niobium (Nb) alloy of zirconium (Zr–2.5Nb) has recently been introduced as a bearing surface for the femoral component in hip arthroplasty. The advantage is that the surface of the metal can be transformed into a relatively thick (micrometers) zirconium oxide (i.e., zirconia) ceramic-like material, thus combining the benefits of ceramic and metal in one component. The oxide layer is not a coating but rather the surface zone of the metal alloy. The oxide/metal interface is continuous, without pores or voids which might be detrimental to oxide adhesion. The ceramic like zirconia surface layer is highly adherent to the metal alloy and further supported the use of this novel alloy as a scratch-resistant counterface for total joint replacement prostheses. Laboratory studies have demonstrated the superior wear performance of oxidized zirconium against polyethylene in comparison with cobalt–chromium alloy. This paper comments the advantage of this new bearing surface for hip replacement.

Résumé

S’il est connu depuis longtemps que les têtes en céramique assurent un meilleur couple de frottement face au polyéthylène que les têtes en métal, la céramique présente l’inconvénient du risque de fracture. C’est pour éviter ces inconvénients qu’un nouveau matériau a été créé pour les prothèses de hanche et de genou: il s’agit de l’oxinium qui présente les avantages de la résistance mécanique du métal et les avantages de la surface d’une céramique pour ce qui concerne le couple de frottement. Il s’agit d’un alliage de zirconium-niobium (Zr2.5Nb) qui est oxydé sur 5 microns d’épaisseur et qui a le nom d’oxinium. C’est l’oxydation en surface du métal qui assure la céramisation. Cet oxyde n’est pas un revêtement appliqué mais une transformation de la surface métallique d’origine en céramique d’oxyde de zirconium due à la saturation en oxygène. Il n’y a donc pas de discontinuité des caractéristiques mécaniques observée dans le cas de couches céramiques déposées. Ceci permet d’obtenir un oxyde dense, à grains fins, d’une épaisseur d’environ 5 microns et sans craquelure. Les études en laboratoire ont montré la supériorité de ce nouveau matériau lorsqu’il est comparé avec le chrome cobalt dans les couples de frottement avec le polyéthylène. Ces papiers commentent les avantages et la place de ce nouveau matériau dans les prothèses totales de hanche.

Similar content being viewed by others

References

Dowson D, Tahery S, Wallbridge N (1987) The role of counterface imperfections in the wear of polyethylene. Wear 119:277–293

Greer KW, Hamilton JV, Cheal EJ (1995) Polyethylene wear in orthopedics. In: Wise DL, Trantolo DJ, Altobelli DE, Yaszemski MJ, Gresser JD, Schwartz ER (eds) Encyclopedic handbook of biomaterials and bioengineering, part B: applications, vol 1. Marcel Dekker, New York, pp 613–638

Saikko U, Colonius O, Keranen J (2001) Effect of counterface roughness on the wear of conventional and crosslinked ultrahigh molecular weight polyethylene studied with multidirectional motion pin on disk device. J Biomed Mater Res 57:506–512

Bragdon CR, Jasty M, Muratoglu OK, O’Connor DO, Harris WH (2003) Third-body wear of highly cross-linked polyethylene in a hip simulator. J Arthroplasty 18:553–561

MacDonald SJ, McCalden RW, Chess D et al (2003) Metal-on-metal versus polyethylene in total hip arthroplasty: a randomized clinical trial. Clin Orthop Relat Res 406:282–296

Clarke I, Willmann G (1994) Structural ceramics in orthopaedics. In: Cameron H (ed) Bone implant interface. St. Louis, Mosby, pp 203–252

Oonishi H, Wakitani S, Murata N et al (2000) Clinical experience with ceramics in total hip replacement. Clin Orthop Relat Res 379:77–84

Benezra V, Mangin S, Treska M, Spector M, Hunter G, Hobbs LW (1999) Microstructural investigation of the oxide scale on Zr–2.5 Nb and its interface with the alloy substrate. Mat Res Soc Symp Proc 550:337–342

Mishra A, Davidson J (1993) Zirconia/zirconium: a new abrasion resistant material for orthopaedic applications. Mater Tech 8:16–21

Good V, Ries MD, Barrack RL et al (2003) Reduced wear with oxidized zirconium femoral heads. J Bone Joint Surg 85A:105–110

Ries MD, Salehi A, Widding K, Hunter G (2002) Polyethylene wear performance of oxidized zirconium and cobalt chromium knee components under abrasive conditions. J Bone Joint Surg 84A(Suppl 2):129–135

Sprague J, Salehi A, Tsai S et al (2003) Mechanical behaviour of zirconia, alumina and oxidized zirconium modular heads. In: Brown S, Clarke IC, Gustafson A (eds) ISTA, vol 2. International Society for Technology in Arthroplasty, Birmingham, 2004, pp 31–36

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hernigou, P., Mathieu, G., Poignard, A. et al. Oxinium, a new alternative femoral bearing surface option for hip replacement. Eur J Orthop Surg Traumatol 17, 243–246 (2007). https://doi.org/10.1007/s00590-006-0180-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00590-006-0180-2