Abstract

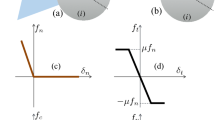

Numerical simulations with the Discrete Element Method are used to study agglomerate breakage under two different kinds of dynamic loading: normal impact and shear loading. Simple mechanical models based on energy balance are developed herein for each one and show good agreement with the results of the simulations. For impact, damage is found to depend on a dimensionless number N i , which describes the ratio of the incoming kinetic energy to the internal bonding energy. For shear loading, damage is shown to depend on another dimensionless number N f which describes the ratio of the frictional work to the internal bonding energy. The friction force is first modelled as a solid-like friction force, then the model is improved by using a granular frictional force. The two types of loading as damaging processes are then compared. These results appear to be consistent with the available experimental data on impact and abrasion wear tests.

Similar content being viewed by others

References

Andrews E.W., Kim K.S.: Threshold conditions for dynamic fragmentation of ceramic particles. Mech. Mater. 29(3–4), 161–180 (1998)

Andrews E.W., Kim K.S.: Threshold conditions for dynamic fragmentation of glass particles. Mech. Mater. 31(11), 689–703 (1999)

Arbiter N., Harris C.C., Stamboltzis G.A.: Single fracture of brittle spheres. Trans. SME 244, 118–133 (1969)

Attal M., Lave J.: Pebble erosion by interparticle collision during fluvial transport: experimental results and implications for the evolution of sediment load along rivers. J. Geophys. Res. F. Earth Surf. 114, F04023 (2009)

Bagi K.: An algorithm to generate random dense arrangements for discrete element simulations of granular assemblies. Granul. Matter 7(1), 31–43 (2005)

Behera B., Kun F., McNamara S., Herrmann H.J.: Fragmentation of a circular disc by impact on a frictionless plate. J. Phys. Conden. Matter 17(24), S2439–S2456 (2005)

Carmona H.A., Wittel F.K., Kun F., Herrmann H.J.: Fragmentation processes in impact of spheres. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 77(5), 243–253 (2008)

Chang C.S., Chao S.J., Chang Y.: Estimates of elastic moduli for granular material with anisotropic random packing structure. Int. J. Solids Struct. 32(14), 1989–2008 (1995)

Chau K.T., Wei X.X., Wong R.H.C., Yu T.X.: Fragmentation of brittle spheres under static and dynamic compressions: experiments and analyses. Mech. Mater. 32(9), 543–554 (2000)

Chenje T., Radziszewski P.: Determining the steel media abrasive wear as a function of applied force and friction. Miner. Eng. 17(11–12), 1255–1258 (2004)

Cundall P.A., Strack O.D.L.: Discrete numerical model for granular assemblies. Geotechnique 29(1), 47–65 (1979)

Czichos H., Klaffke D., Santner E., Woydt M.: Advances in tribology: the materials point of view. Wear 190(2), 155–161 (1995)

Estrada, N., Taboada, A., Radjai, F.: Role des parametres locaux de cohesion dans la resistance mecanique d’un milieu granulaire cohesif. 18eme Congres Francais de Mecanique, Grenoble 27–31 aout 2007 (2007)

Farrow, J.W., Sklar, L.S.: Lithologic influence and experimental variability in gravel abrasion: implications for predicting rates of downstream fining of river bed sediments. GSA Cordilleran Section Annual Meeting, Geological Society of America Abstracts with Programs 37(4) (2005)

Fillot N., Iordanoff I., Berthier Y.: Modelling third body flows with a discrete element method-a tool for understanding wear with adhesive particles. Tribol. Int. 40(6), 973–981 (2007)

Godet M.: The third-body approach: a mechanical view of wear. Wear 100(1–3), 437–452 (1984)

Gorham D.A., Salman A.D.: The failure of spherical particles under impact. Wear 258(1–4), 580–587 (2005)

Jop P., Forterre Y., Pouliquen O.: A constitutive law for dense granular flows. Nature 441(7094), 727–730 (2006)

Kafui K.D., Thornton C.: Computer simulated impact of agglomerates. In: Thornton, C. (ed.) Powders and Grains, pp. 401–406. Balkema, Rotterdam (1993)

Khanal M., Morrison R.: Discrete element method study of abrasion. Miner. Eng. 21(11), 751–760 (2008)

Khanal M., Schubert W., Tomas J.: Ball impact and crack propagation—simulations of particle compound material. Granul. Matter 5(4), 177–184 (2004)

Kodama Y.: Downstream changes in the lithology and grain size of fluvial gravels, the Watarase River, Japan: evidence of the role of abrasion in downstream fining. J. Sediment. Res A Sediment. Petrol. Process. 64((1), 68–75 (1994)

Kuenen P.H.: Experimental abrasion of pebbles: 2. Rolling by currents. J. Geol. 64, 336–368 (1956)

Meng H.C., Ludema K.C.: Wear models and predictive equations: their form and content. Wear 181–183(PART 2), 443–457 (1995)

Mishra B.K.: A review of computer simulation of tumbling mills by the discrete element method: part I-contact mechanics. Int. J. Miner. Process. 71(1–4), 73–93 (2003)

Moreno-Atanasio R., Ghadiri M.: Mechanistic analysis and computer simulation of impact breakage of agglomerates: effect of surface energy. Chem. Eng. Sci. 61(8), 2476–2481 (2006)

Morrison R.D., Cleary P.W.: Using DEM to model ore breakage within a pilot scale SAG mill. Miner. Eng. 17(11–12), 1117–1124 (2004)

Prochnow, M.: Ecoulements denses de grains secs. Phd thesis, Ecole Nationale des Ponts et Chaussees (2002)

Salman A.D., Biggs C.A., Fu J., Angyal I., Szab M., Hounslow M.J.: An experimental investigation of particle fragmentation using single particle impact studies. Powder Technol. 128(1), 36–46 (2002)

Srinath G., Gnanamoorthy R.: Two-body abrasive wear characteristics of Nylon clay nanocomposites–effect of grit size, load, and sliding velocity. Mater. Sci. Eng. A. 435–436, 181–186 (2006)

Srinath G., Gnanamoorthy R.: Effect of organoclay addition on the two-body abrasive wear characteristics of polyamide 6 nanocomposites. J. Mater. Sci. 42(19), 8326–8333 (2007)

Subero, J., Ghadiri, M.:Breakage patterns of agglomerates. Powder Technol. 120(3), 232–243 (2001)

Thornton C., Ciomocos M., Adams M.: Numerical simulations of agglomerate impact breakage. Powder Technol. 105, 74–82 (1999)

Thornton C., Yin K.K., Adams M.J.: Numerical simulation of the impact fracture and fragmentation of agglomerates. J. Phys. D Appl. Phys. 29(2), 424–435 (1996)

Vogel L., Peukert W.: Breakage behaviour of different materials–construction of a mastercurve for the breakage probability. Powder Technol. 129(1–3), 101–110 (2003)

Wu S.Z., Chau K.T., Yu T.X.: Crushing and fragmentation of brittle spheres under double impact test. Powder Technol. 143–144, 41–55 (2004)

Zhou F., Molinari J.F., Ramesh K.T.: Effects of material properties on the fragmentation of brittle materials. Int. J. Fract. 139(2), 169–196 (2006)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Le Bouteiller, C., Naaim, M. Aggregate breakage under dynamic loading. Granular Matter 13, 385–393 (2011). https://doi.org/10.1007/s10035-010-0235-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10035-010-0235-2