Abstract

Phenol-formaldehyde resin-bonded particleboard (PF board) and isocyanate resin-bonded particleboard (MDI board) were soaked in water at 40, 70 and 100 °C, and the relationships between soaking conditions and nail joint properties were analyzed. The soaking time to reach the lower limit of nail-head pull-through (NHPT) of the PF board was 2 h at 100 °C, while it took 168 h at 70 °C. The soaking time to reach the lower limit of lateral nail resistance (LNR) of the PF board was 24 h at 100 °C, but it did not take 168 h at 70 °C to reach it. The lower limits of NHPT and LNR for the MDI board were higher than those for the PF board. For the PF board, there was a high correlation between modulus of rupture, internal bond strength and nail joint properties. Based on the results of water soaking and outdoor exposure, it was shown that thickness change has a significant effect on NHPT and LNR, and that the reduction in NHPT and LNR results from the collapse of bonding points owing to swelling of the board.

Similar content being viewed by others

Introduction

To evaluate the durability of wood-based boards, a number of accelerated aging tests are used [1–4], most of which involve water soaking at various temperatures. In JIS A 5908, for example, the A test uses 2 h water soaking at 70 °C, and the B test uses 2 h water soaking at 100 °C [5]. For the Engineered Wood Products Association, the test uses 8 h water soaking at 66 °C followed by 14.5 h drying at 82 °C [6]. Although the most widely used accelerated aging test uses water soaking at various temperatures and times, no optimum test has yet been decided upon.

Given that boards are nailed when used for structural purposes, it is important to clarify the effects of water soaking on the properties of these boards. However, water soaking tests have been conducted not to assess nail joint property, but to assess the modulus of rupture (MOR) and internal bond strength (IB), which hereafter are defined as basic properties. Moreover, the relationships between nail joint properties and the basic properties of the board soaked in water have not been clarified.

In a previous study [7], to develop an optimum accelerated aging test, the effects of water-soaking temperature and time on the basic properties were ascertained. These basic properties were found to decrease with increasing water-soaking time, and after a certain increase in the soaking time, the values remained constant. This constant value is defined as the “lower limit”.

To develop at optimum accelerated aging test, it is very important to ascertain the effects of water-soaking temperature and time on nail joint properties. The purpose of this study is to reveal the effects and existence of the lower limit. Moreover, the relationships between nail joint properties and basic properties are shown.

In an experiment, nailed boards were exposed outdoors at four sites in Japan for 7 years (2004–2011), and the nail joint properties were evaluated [8, 9]. The relationships between nail joint properties owing to water soaking and those owing to outdoor exposure were then compared and analyzed.

Experimental

Particleboards used in this experiment

Phenol-formaldehyde resin-bonded particleboard (PF board) and methylene diphenyl diisocyanate resin-bonded particleboard (MDI board) were used in the experiments. Further details are provided in the references [8–11]. The boards were commercial products that did not include detailed information such as binder content. Both types of board satisfied the waterproof category of Type 18 and Type P under JIS A 5908 [5]. Type 18 satisfies 18 MPa in MOR and Type P indicates waterproof boards. The initial board properties of the PF board and the MDI board are shown in Table 1. Thirty specimens each were used for measuring the initial values of MOR, IB, nail-head pull-through (NHPT) and lateral nail resistance (LNR). The MOR and IB tests were conducted in compliance with JIS A 5908 [5]. The NHPT and LNR tests were then conducted in compliance with American Society for Testing and Materials (ASTM D-1037) [12].

Water soaking conditions

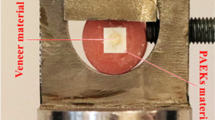

Nailed specimens measuring 275 × 50 mm were soaked in water at 40, 70 and 100 °C (Fig. 1). Soaking times at 40 °C were 2, 12 and 336 h, at 70 °C were 1, 2, 6, 24 and 168 h and at 100 °C were 1, 2, 6, 24 and 72 h, respectively. Stainless steel nails (SUS304, 50 mm in length, 6.3 mm in head diameter and 2.8 mm in shank diameter) were driven into the specimens.

Outdoor exposure

Twelve nailed specimens (PF board) measuring 300 × 300 mm were set up on an exposure stand that faced south at an angle of 90° to the ground (Fig. 2). Stainless steel nails were driven into the boards (Fig. 2). The cut edges of the specimens were not coated with enamel paint as a waterproof agent prior to outdoor exposure. Two specimens were collected for testing at 1–5 and 6 or 7 years to evaluate the board properties. The outdoor exposure was conducted at four sites in Japan: Morioka, Tsukuba, Okayama and Miyakonojo. Morioka and Tsukuba are in northern Japan, and Okayama and Miyakonojo are in southern Japan. Table 2 lists the latitude, longitude and climate conditions of these four sites from February 2004 to March 2011. The nailed PF boards were exposed outdoors to investigate the nail joint property; nailed MDI boards were not exposed because very few of these boards were available. Details on the outdoor exposure can be found in the references [8–11].

Board property tests

Specimens soaked in water were dried in an oven at 30 °C for 48 h and subsequently conditioned at a constant temperature of 20 °C and relative humidity of 65 % for 7–10 days until the weight stabilized. After conditioning, the thickness of the specimens was measured to determine the resulting changes (Fig. 1). The change in thickness (thickness change) is calculated by the following relation:

where t 0 and t 1 are the air-dried thickness before and after the accelerated aging test, respectively. Specimens measuring 50 × 50 and 100 × 50 mm used for the NHPT and LNR tests, respectively, were taken from the 275 × 50 mm specimens. Specimens exposed outdoors were also conditioned, and specimens measuring 50 × 50 and 90 × 50 mm used for the NHPT and LNR tests, respectively, were taken from the 300 × 300 mm specimens. The number of specimens of NHPT and LNR soaked in water were 5 and 5. The number of specimens of NHPT and LNR exposed outdoors were 8 and 6, respectively. The MOR, IB, NHPT and LNR retention are calculated by the following relation:

When the change in specimen thickness was used to analyze the variations in MOR, IB, NHPT and LNR of boards exposed outdoors, it was calculated using the thickness of the specimen measuring 300 × 300 mm before outdoor exposure and the thickness of the MOR specimen after outdoor exposure.

Results and discussion

Nail-head pull-through of boards soaked in water

Figure 3a shows the relationships between soaking time and the NHPT retention of the PF board. The NHPT retention at 40 °C decreased with increasing soaking time, but the NHPT retention was as high as 81.5 % at 336 h. At 70 °C, the NHPT retention decreased to 69.9 % as the soaking time increased to 168 h. The NHPT retention at 40 and 70 °C decreased with increasing soaking time, while at 100 °C it decreased to 81.6 % at 1 h. It decreased to 71.1 % at 2 h and leveled off at 70 % with increasing soaking time. Thus, the lower limit must be approximately 70 %.

Figure 3b shows the relationships between soaking time and the NHPT retention of the MDI board. Unlike the PF board, at 40 °C, the NHPT retention did not decrease with increasing soaking time. At 70 °C, the NHPT retention decreased with increasing soaking time, but it was as high as 84.9 %. At 100 °C, it was approximately 85 %, irrespective of soaking time. Thus, the lower limit is presumably approximately 85 %.

Lateral nail resistance of boards soaked in water

Figure 4a shows the relationships between soaking time and the LNR retention of the PF board. At 40 °C, the LNR retention decreased to 74.2 % at 336 h. At 70 °C, it decreased to 62.5 % at 168 h. At 100 °C, it decreased to 47.2 % at 24 h and leveled off at approximately 50 %. Thus, the lower limit must be approximately 50 %.

Figure 4b shows the relationships between soaking time and the LNR retention of the MDI board. An LNR retention that exceeded 100 % was recorded as 100 %. At 40 °C, the LNR retention was as high as 100 % irrespective of soaking time. At 70 °C, it was 100 % until 6 h and subsequently decreased slightly. At 100 °C, it decreased slightly with increasing soaking time and it was as high as 86.9 % at 72 h. Thus, the lower limit must be approximately 90 %. Furthermore, the LNR retention of the MDI board was higher than that of the PF board and did not decrease significantly even with prolonged soaking at 100 °C.

Relationships between thickness swelling and board properties (MOR, IB, NHPT and LNR)

The thickness of the swollen board caused a reduction in the values of board properties (MOR, IB, NHPT and LNR) owing to water soaking [7]. It is therefore important to analyze the relationships between thickness change and these properties. In Fig. 5, which shows these relationships for the PF board, the retention of MOR, IB, and LNR decreased linearly as the thickness change increased, with high negative correlation coefficients of −0.93, −0.94 and −0.92, respectively. The value of NHPT also decreased linearly with increasing thickness change, but at −0.85 the negative correlation coefficient of NHPT was lower than those of MOR, IB and LNR. Thus, the values of MOR, IB and LNR were predicted using the thickness change. However, it was more difficult to predict the value of NHPT.

Relationships between thickness change and MOR and IB retention of PF board (a). Relationships between thickness change and NHPT and LNR retention of PF board (b). MOR modulus of rupture, IB internal bond strength, NHPT nail-head pull-through, LNR lateral nail resistance, PF board phenol-formaldehyde resin-bonded particleboard, r correlation coefficient

Figure 6 shows the relationships between thickness change and board properties of the MDI board. The retention of MOR, IB, NHPT and LNR of the MDI board were higher than those of the PF board; the MDI board exhibited lower thickness change than the PF board; the MDI board was also more durable than the PB board. Therefore, the negative correlation coefficient of the MDI board was lower than that of the PF board.

Relationships between thickness change and MOR and IB retention of MDI board (a). Relationships between thickness change and NHPT and LNR retention of MDIboard (b). MOR modulus of rupture, IB internal bond strength, NHPT nail-head pull-through, LNR lateral nail resistance, MDI board isocyanate resin-bonded particleboard, r correlation coefficient

Relationships between nail joint properties and basic properties

Figure 7a shows the relationships between MOR retention and NHPT retention of the PF board, while Fig. 7b shows the relationships between MOR retention and LNR retention of the PF board. NHPT retention and LNR retention increased linearly with increasing MOR retention, with high positive correlation coefficients of 0.93 and 0.93, respectively. Figure 8a shows the relationships between IB retention and NHPT retention, and Fig. 8b shows the relationships between IB retention and LNR retention; the correlation coefficients were 0.93 and 0.93, respectively. As shown in Fig. 8, both the NHPT and LNR retention also increased linearly with increased IB retention. Figure 5 shows that the negative correlation coefficient of NHPT as a function of thickness change was lower. However, these results implied that the values of MOR and IB could be used to predict the values of NHPT and LNR. In general, as the NHPT and LNR tests are cumbersome, the ability to predict NHPT and LNR is very important.

Relationships between MOR retention and NHPT retention of PF board (a). Relationships between MOR retention and LNR retention of PF board (b). MOR modulus of rupture, NHPT nail-head pull-through, LNR lateral nail resistance, PF board phenol-formaldehyde resin-bonded particleboard, r correlation coefficient

Relationships between IB retention and NHPT retention of PF board (a). Relationships between IB retention and LNR retention of PF board (b). IB internal bond strength, NHPT nail-head pull-through, LNR lateral nail resistance, PF board phenol-formaldehyde resin-bonded particleboard, r correlation coefficient

Figures 9 and 10 show the relationships between basic properties and nail joint properties of the MDI board. As discussed previously, the nail joint properties of the MDI board did not decrease greatly. Furthermore, the MOR and IB of the MDI board did not decrease more significantly than those of PF board [7]. When the basic properties of the PF board decreased, the nail joint properties also decreased. On the other hand, the basic properties of the MDI board decreased significantly, but the nail joint properties did not. Phenol-formaldehyde resin and isocyanate resin are highly durable binders [13], and they do not decompose. However, the initial IB of isocyanate resin is much higher than that of phenol-formaldehyde resin (Table 1), which results in high initial basic and high nail joint properties of the MDI board; these high initial properties result in low thickness change [7]. These high initial properties presumably led to retain high properties after water soaking.

Reduction mechanism of nail joint properties owing to outdoor exposure

In the previous study [7], the effects of thickness change on the basic properties of boards owing to water soaking and outdoor exposure were shown: the higher the thickness change, the lower the basic properties. It was also shown that the reduction trend of the basic properties owing to water soaking was different from that owing to outdoor exposure. Figure 11a shows the relationships between the thickness change and the NHPT retention of the PF board exposed outdoors and soaked in water. The “Outdoor (North)” labels represent Morioka and Tsukuba, and the “Outdoor (South)” labels represent Okayama and Miyakonojo. The NHPT retention of both water soaking and outdoor exposure decreased with increasing thickness change. The thickness change of outdoor exposure (North) was lower than that of outdoor exposure (South). The reduction trend for the NHPT of PF board exposed outdoors was almost the same as that of PF board soaked in water.

Relationships between thickness and NHPT retention of PF board (a). Relationships between thickness change and LNR retention of PF board (b). NHPT nail-head pull-through, LNR lateral nail resistance, PF board phenol-formaldehyde resin-bonded particleboard. Outdoor exposure (North): Morioka and Tsukuba; Outdoor exposure (South): Okayama and Miyakonojo

Figure 11b shows the relationships between thickness change and the LNR retention of PF board exposed outdoors and soaked in water. The LNR retention decreased with increasing thickness change. Moreover, the LNR retention of PF board exposed outdoors was lower than that of PF board soaked in water. In board exposed outdoors, the deterioration of the edge was different from that of the center, with the former more prone to deteriorate than the latter. In particular, the former was also more prone to biodegrade. In compliance with ASTM, the LNR was conducted at the edge of the board and the NHPT was conducted at the center of the board [12]. The LNR of the board exposed outdoors was measured at the edge, whereas the NHPT of the board exposed outdoors was measured at the center (Fig. 2) [8]. Thus, the LNR of board exposed outdoors decreased more than that of board soaked in water. As for the basic properties, thickness change was shown to have a significant affect on nail joint properties. The high thickness change results in the collapse of the bonding points, which induces a decrease in bonding strength. The decreased strength of the bonding points causes a decrease in the strength of the nail joint properties.

Conclusions

The soaking time to reach the lower limit of NHPT of the PF board was 2 h at 100 °C, while it took 168 h to reach it at 70 °C. The soaking time to reach the lower limit of LNR of the PF board was 24 h at 100 °C, but it did not take 168 h at 70 °C to reach it. The lower limit of the nail joint properties of the MDI board was very high. For the PF board, there was a high correlation between nail joint properties and basic properties. The nail joint properties of the MDI board having high initial MOR and IB did not significantly decrease as a result of high-temperature water soaking. If nailed MDI boards were subjected to outdoor exposure, the nail joint properties would be retained owing to high initial MOR and IB.

References

Kajita H, Mukudai J, Yano H (1991) Durability evaluation of particleboards by accelerated aging tests. Wood Sci Technol 25:239–249

Alexopoulos J (1992) Accelerated aging and outdoor weathering of aspen waferboard. Forest Prod J 42(2):15–22

McNatt JD, McDonald D (1993) Two accelerated-aging tests for wood-based panels. Forest Prod J 43(7/8):49–52

Okkonen EA, River BH (1996) Outdoor aging of wood-based panels and correlation with laboratory aging: part 2. Forest Prod J 46(3):68–74

Japanese Industrial Standards JIS A 5908 (2003) JIS standard specification for particleboard, Japanese Standards Association, Tokyo

APA Standard PRP-108 (1994) Performance standards and policies for structural-use panels. The Engineered Wood Products Association, Tacoma

Korai H, Saotome H, Ohmi M (2013) Effects of water soaking and outdoor exposure on modulus of rupture and internal bond strength of particleboard. J Wood Sci. doi:10.1007/s10086-013-1374-y

Korai H, Adachi K, Saotome H (2013) Deterioration of wood-based boards subjected to outdoor exposure in Tsukuba. J Wood Sci 59:24–34

Korai H (2012) Durability of medium density fiberboard subjected to outdoor exposure (in Japanese). Mokuzai Gakkaishi 58:347–356

Sekino N, Korai H (2005) Second durability evaluation project of wood-based panel (in Japanese). J Timber Eng 18:110–117

Korai H, Sekino N, Saotome H (2012) Effects of outdoor exposure angle on the deterioration of wood-based board properties. Forest Prod J 62:184–190

American Society for Testing and Materials ASTM D1037-96a (1996) Standard methods of evaluating the properties of wood-base fiber and particle panel materials

Korai H (2012) Improvement of acetylated fiberboard by ozonization (in Japanese). J Adhesion Soc Jpn 48:30–35

Acknowledgments

This study was supported by a grant from LIXIL JS Foundation, a Grant-in-Aid for Scientific Research (21380108) from the Ministry of Education, Culture, Sports, Science and Technology of Japan, and an Emachu Research Fund. The authors are grateful for the grants received. The outdoor exposure test was conducted as part of a project organized by the Research Working Group on Wood-based Panels from the Japan Wood Research Society. The authors express their thanks to all participants in this project.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Korai, H., Saotome, H. Effects of water soaking and outdoor exposure on nail joint properties of particleboard. J Wood Sci 60, 134–140 (2014). https://doi.org/10.1007/s10086-013-1375-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10086-013-1375-x