Abstract

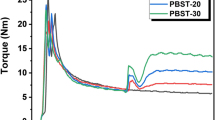

Sustainable blends of poly(propylene carbonate) (PPC) and stereocomplex polylactide (sc-PLA) were prepared by melt blending equimolar poly(L-lactic acid) (PLLA) and poly(D-lactide acid) (PDLA) with PPC to form sc-PLA crystals in situ in the melt blending process. Differential scanning calorimetry analysis revealed that only sc-PLA, no homo-crystallization of PLLA or PDLA, formed in the PPC matrix as the sc-PLA content was more than 10 wt%. Very intriguingly, scanning electronic microscopy observation showed that sc-PLA was evenly dispersed in the PPC phase as spherical particles and the sizes of sc-PLA particles did not obviously increase with increasing sc-PLA content. As a consequence, the rheological properties of PPC were greatly improved by incorporation of sc-PLA. When the sc-PLA content was 20 wt%, a percolation network structure was formed, and the blends showed solid-like behavior. The sc-PLA particles could reinforce the PPC matrix, especially at a temperature above the glass transition temperature of PPC. Moreover, the Vicat softening temperature of PPC/sc-PLA blends could be increased compared with that of neat PPC.

Similar content being viewed by others

References

Muthuraj, R.; Mekonnen, T. Recent progress in carbon dioxide (CO2) as feedstock for sustainable materials development: copolymers and polymer blends. Polymer2018, 145, 348–373.

Yang, Z. Z.; He, L. N.; Gao, J.; Liu, A. H.; Yu, B. Carbon dioxide utilization with CN bond formation: carbon dioxide capture and subsequent conversion. Energy Environ. Sci.2012, 5, 6602–6639.

Williams, C. K.; Hillmyer, M. A. Polymers from renewable resources: a perspective for a special issue of polymer reviews. Polym. Rev.2008, 48, 1–10.

Honda, S.; Mori, T.; Goto, H.; Sugimoto, H. Carbon-dioxide-derived unsaturated alicyclic polycarbonate: synthesis, characterization, and post-polymerization modification. Polymer2014, 55, 4832–4836.

Darensbourg, D. J.; Wei, S.; Yeung, A. D.; Ellis, W. C. An efficient method of depolymerization of poly(cyclopentene carbonate) to its comonomers: cyclopentene oxide and carbon dioxide. Macromolecules2013, 46, 5850–5855.

Xu, J. W.; Feng, E.; Song, J. Renaissance of aliphatic polycarbonates: new techniques and biomedical applications. J. Appl. Polym. Sci.2014, 131, 39822.

Udipi, K.; Gillham, J. K. Poly(ethylene carbonate) and poly(propylene carbonate): transitions and thermomechanical spectra. J. Appl. Polym. Sci.1974, 18, 1575–1580.

Phillips, O.; Schwartz, J. M.; Kohl, P. A. Thermal decomposition of poly(propylene carbonate): end-capping, additives, and solvent effects. Polym. Degrad. Stab.2016, 125, 129–139.

Bahramian, B.; Ma, Y.; Rohanizadeh, R.; Chrzanowski, W.; Dehghani, F. A new solution for removing metal-based catalyst residues from a biodegradable polymer. Green Chem.2016, 18, 3740–3748.

Zhuo, C. W.; Qin, Y. S.; Wang, X. H.; Wang, F. S. Steric hindrance ligand strategy to aluminum porphyrin catalyst for completely alternative copolymerization of CO2 and propylene oxide. Chinese J. Polym. Sci.2018, 36, 252–260.

Tao, Y. H.; Wang, X. H.; Zhao, X. J.; Li, J.; Wang, F. S. Double propagation based on diepoxide, a facile route to high molecular weight poly(propylene carbonate). Polymer2006, 47, 7368–7373.

Muthuraj, R.; Misra, M.; Mohanty, A. K. Biodegradable compatibilized polymer blends for packaging applications: a literature review. J. Appl. Polym. Sci.2018, 135, 45726.

Yao, M. Modification of poly(lactic acid)/poly(propylene carbonate) blends through melt compounding with maleic anhydride. Express Polym. Lett.2011, 5, 937–949.

Zhou, L. Y.; Zhao, G. Y.; Jiang, W. Effects of catalytic transesterification and composition on the toughness of poly(lactic acid)/poly(propylene carbonate) blends. Ind. Eng. Chem. Res.2016, 55, 5565–5573.

Qin, S. X.; Yu, C. X.; Chen, X. Y.; Zhou, H. P.; Zhao, L. F. Fully biodegradable poly(lactic acid)/poly(propylene carbonate) shape memory materials with low recovery temperature based on in situ compatibilization by dicumyl peroxide. Chinese J. Polym. Sci.2018, 36, 783–790.

Corre, Y. M.; Bruzaud, S.; Grohens, Y. Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and poly(propylene carbonate) blends: an efficient method to finely adjust properties of functional materials. Macromol. Mater. Eng.2013, 298, 1176–1183.

Peng, S. W.; An, Y. X.; Chen, C.; Fei, B.; Zhuang, Y. G.; Dong, L. S. Miscibility and crystallization behavior of poly(3-hydroxyvalerate-co-3-hydroxyvalerate)/poly (propylene carbonate) blends. J. Appl. Polym. Sci.2003, 90, 4054–4060.

Li, J. H.; Lai, M. F.; Liu, J. J. Control and development of crystallinity and morphology in poly(β-hydroxybutyrate-co-β-hydroxyvalerate)/poly(propylene carbonate) blends. J. Appl. Polym. Sci.2005, 98, 1427–1436.

El-Hadi, A. M. Improvement of the miscibility by combination of poly(3-hydroxy butyrate) PHB and poly(propylene carbonate) PPC with additives. J. Polym. Environ.2017, 25, 728–738.

Yang, D. Z.; Hu, P. Miscibility, crystallization, and mechanical properties of poly(3-hydroxybutyrate) and poly(propylene carbonate) biodegradable blends. J. Appl. Polym. Sci.2008, 109, 1635–1642.

Chen, G. J.; Wang, Y. Y.; Wang, S. J.; Xiao, M.; Meng, Y. Z. Orientation microstructure and properties of poly(propylene carbonate)/poly(butylene succinate) blend films. J. Appl. Polym. Sci.2013, 128, 390–399.

Pang, M. Z.; Qiao, J. J.; Jiao, J.; Wang, S. J.; Xiao, M.; Meng, Y. Z. Miscibility and properties of completely biodegradable blends of poly(propylene carbonate) and poly(butylene succinate). J. Appl. Polym. Sci.2008, 107, 2854–2860.

Zeng, S. S.; Wang, S. J.; Xiao, M.; Han, D. M.; Meng, Y. Z. Preparation and properties of biodegradable blend containing poly(propylene carbonate) and starch acetate with different degrees of substitution. Carbohydr. Polym.2011, 86, 1260–1265.

Ge, X. C.; Li, X. H.; Zhu, Q.; Li, L.; Meng, Y. Z. Preparation and properties of biodegradable poly(propylene carbonate)/starch composites. Polym. Eng. Sci.2004, 44, 2134–2140.

Chen, L.; Hu, K.; Sun, S.; Jiang, H.; Huang, D.; Zhang, K. Y.; Pan, L.; Li, Y. S. Toughening poly(lactic acid) with imidazolium-based elastomeric ionomers. Chinese J. Polym. Sci.2018, 36, 1342–1352.

Tsuji, H. Poly(lactide) stereocomplexes: formation, structure, properties, degradation, and applications. Macromol. Biosci.2005, 5, 569–597.

Wang, M.; You, L. C.; Guo, Y. Q.; Jiang, N.; Gan, Z. H.; Ning, Z. B. Enhanced crystallization rate of poly(L-lactide)/hydroxyapatite-graft-poly(D-lactide) composite with different processing temperatures. Chinese J. Polym. Sci.2020, doi: https://doi.org/10.1007/s10118-020-2374-1.

Shao, J.; Liu, Y. L.; Xiang, S.; Bian, X. C.; Sun, J. R.; Li, G.; Chen, X. S.; Hou, H. Q. The stereocomplex formation and phase separation of PLLA/PDLA blends with different optical purities and molecular weights. Chinese J. Polym. Sci.2015, 33, 1713–1720.

Bouapao, L.; Tsuji, H. Stereocomplex crystallizationand spherulite growthoflow molecular weight poly(L-lactide) and poly(D-lactide) from the melt. Macromol. Chem. Phys.2009, 210, 993–1002.

Wang, G.; Zhang, D. M.; Li, B.; Wan, G. P.; Zhao, G. Q.; Zhang, A. M. Strong and thermal-resistance glass fiber-reinforced polylactic acid (PLA) composites enabled by heat treatment. Int. J. Biol. Macromol.2019, 129, 448–459.

Li, W.; Sun, Q. S.; Mu, B. N.; Luo, G. Q.; Xu, H. L.; Yang, Y. Q. Poly(L-lactic acid) bio-composites reinforced by oligo(D-lactic acid) grafted chitosan for simultaneously improved ductility, strength and modulus. Int. J. Biol. Macromol.2019, 131, 495–504.

Tsuji, H.; Horii, F.; Hyon, S. H.; Ikada, Y. Stereocomplex formation between enantiomeric poly(lactic acid)s. 2. Stereocomplex formation in concentrated solutions. Macromolecules1991, 24, 2719–2724.

Tsuji, H.; Ikada, Y. Stereocomplex formation between enantiomeric poly(lactic acid)s. 6. Binary blends from copolymers. Macromolecules1992, 25, 5719–5723.

Bao, R. Y.; Yang, W.; Jiang, W. R.; Liu, Z. Y.; Xie, B. H.; Yang M. B. Polymorphism of racemic poly(L-lactide)/poly(D-lactide) blend: effect of melt and cold crystallization. J. Phys. Chem. B2013, 117, 3667–3674.

Bao, R. Y.; Yang, W.; Jiang, W. R.; Liu, Z. Y.; Xie, B. H.; Yang, M. B.; Fu, Q. Stereocomplex formation of high-molecular-weight polylactide: a low temperature approach. Polymer2012, 53, 5449–5454.

Tsuji, H.; Horii, F.; Nakagawa, M.; Ikada, Y.; Odani, H.; Kitamaru, R. Stereocomplex formation between enantiomeric poly(lactic acid)s. 7. Phase structure of the stereocomplex crystallized from a dilute acetonitrile solution as studied by high-resolution solidstate carbon-13 NMR spectroscopy. Macromolecules1992, 25, 4114–4118.

Qin, Y. S.; Sheng, X. F.; Liu, S. J.; Ren, G. J.; Wang, X. H.; Wang, F. S. Recent advances in carbon dioxide based copolymers. J. CO2Util.2015, 11, 3–9.

Li, Y.; Han, C. Y.; Yu, Y. C.; Huang, D. X. Morphological, thermal, rheological and mechanical properties of poly(butylene carbonate) reinforced by stereocomplex polylactide. Int. J. Biol. Macromol.2019, 137, 1169–1178.

Tsuji, H.; Tashiro, K.; Bouapao, L.; Hanesaka, M. Synchronous and separate homo-crystallization of enantiomeric poly(L-lactic acid)/poly(D-lactic acid) blends. Polymer2012, 53, 747–754.

Han, C. Y.; Ran, X. H.; Su, X.; Zhang, K. Y.; Liu, N. A.; Dong, L. S. Effect of peroxide crosslinking on thermal and mechanical properties of poly(ε-caprolactone). Polym. Int.2007, 56, 593–600.

Liu, H. Z.; Chen, F.; Liu, B.; Estep, G.; Zhang, J. W. Super toughened poly(lactic acid) ternary blends by simultaneous dynamic vulcanization and interfacial compatibilization. Macromolecules2010, 43, 6058–6066.

Chen, F.; Zhang, J. W. A new approach for morphology control of poly(butylene adipate-co-terephthalate) and soy protein blends. Polymer2009, 50, 3770–3777.

Sundararaj, U.; Macosko, C. W. Drop breakup and coalescence in polymer blends: the effects of concentration and compatibilization. Macromolecules1995, 28, 2647–2657.

Horst, R. H.; Winter, H. H. Stable critical gels of a copolymer of ethene and 1-butene achieved by partial melting and recrystallization. Macromolecules2000, 33, 7538–7543.

Shenoy, A. V. in Rheology of filled polymer systems, Springer, Netherlands, 1999, p. 90.

Wu, D. F.; Wu, L.; Zhang, M.; Zhao, Y. L. Viscoelasticity and thermal stability of polylactide composites with various functionalized carbon nanotubes. Polym. Degrad. Stab.2008, 93, 1577–1584.

Kota, A. K.; Cipriano, B. H.; Duesterberg, M. K.; Gershon, A. L.; Powell, D.; Raghavan, S. R.; Bruck, H. A. Electrical and rheological percolation in polystyrene/MWCNT nanocomposites. Macromolecules2007, 40, 7400–7406.

Bouakaz, B. S.; Habi, A.; Grohens, Y.; Pillin, I. Effect of combinations of nanofillers on rheology-structure relations in biodegradable poly(ε-caprolactone) nanocomposites. Appl. Clay. Sci.2018, 161, 35–47.

Han, C. D.; Kim, J. K. On the use of time-temperature superposition in multicomponent/multiphase polymer systems. Polymer1993, 34, 2533–2539.

Li, Y.; Han, C. Y.; Bian, J. J.; Han, L. J.; Dong, L. S.; Gao, G. Rheology and biodegradation of polylactide/silica nanocomposites. Polym. Compos.2012, 33, 1719–1727.

Cole, K. S.; Cole, R. H. Dispersion and absorption in dielectrics: alternating current characteristics. J. Chem. Phys.1941, 9, 341–351.

Li, H. B.; Li, Q.; Yan, M. L. Influence of operation procedures on Vicat softening temperature of thermoplastic materials. Adv. Mater. Res.2011, 291–294, 1820–1824.

Acknowledgments

This work was financially supported by the Chinese Academy of science and technology service network planning (No. KFJ-STS-QYZD-140), a program of Cooperation of Hubei Province and Chinese Academy of Sciences, Innovation team project of Beijing Institute of Science and Technology (No. IG201703N) and “13th five-year” Science and Technology Research Program of the Education Department of Jilin Province (No. JJKH20190862KJ).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Yu, YC., Han, CY. et al. Sustainable Blends of Poly(propylene carbonate) and Stereocomplex Polylactide with Enhanced Rheological Properties and Heat Resistance. Chin J Polym Sci 38, 1267–1275 (2020). https://doi.org/10.1007/s10118-020-2408-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-020-2408-8