Abstract

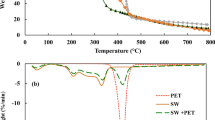

This research studied the characteristics of dried sewage sludge using TGA to co-fire dried sewage sludge with coal in power plants. The sewage sludges that were discharged from Daejeon, Korea were dried and examined fundamental properties to use them as a fuel. Also, the properties of bituminous coal and wood pellet, which are used in domestic coal power plants, were analyzed and compared with them of sewage sludges and non-isothermal analyses of dried sewage sludges were performed at the heating rates of 5, 10, 20, and 30C /min using TG analyzer to investigate the basic combustion characteristics. As a results of these TGA/DTG analyses, sewage sludges showed its primary peak at the temperature of 250–500 °C, which overlapped with main peak of wood and secondary peak at around 500–600 °C, which overlapped with main peak of coals. Also for the interpretation by Friedman method, the activation energies in the section of highest weight loss were 525.16 kJ/mole for dried digested sewage sludge, 544.88 kJ/mole for dried excess sewage sludge, 203.86 kJ/mole for wood pellet and 146.4585 kJ/mole for bituminous coal. The reaction orders for dried digested excess sewage sludge, dried excess sewage sludge, wood pellet and bituminous coal were 28.775, 24.319, 18.398 and 9.1005, respectively, and the frequency factors were 5.89 \(\times \hspace{0.17em}\)1028, 1.65 \(\times \hspace{0.17em}\)1024,, 9.59 \(\times \hspace{0.17em}\)1016 and 1.77 \(\times \hspace{0.17em}\)108 for each, respectively.

Similar content being viewed by others

References

Otero M, Calvo LF, Gil MV, Garcia AI, Moran A (2002) Analysis of the co-combustion of sewage sludge and coal by TG-MS. Biomass Bioenergy 22(4):319–329

Otero M, Calvo LF, Gil MV, Garcia AI, Moran A (2008) Co-combustion of different sewage sludge and coal: a non-isothermal thermogravimetric kinetic analysis. Bioresour Technol 99:6311–6319

Sung Bae Jung, Cheol Gyu Kim (2015) Optimum carbonization condition of sewage sludge for fuel use. J Therm Environ Eng 12(1):1–13

Somi Park, Imhyuk, Cheol Gyu Kim (2015) Evaluation of Combustion Characteristics of carbonized Sewage Sludge by using Thermogravimetric Analysis. J Therm Environ Eng 12(2):74–82

Tsuji H, Hashimoto N, Shirai H, Makino H (2009) A study on combustion characteristics of dried sludge pellets by use of a pulverized coal combustion test furnace. J Jpn Inst Energy 88(5):422–429

Fernando R (2007) Co-firing of coal with waste fuels, CCC/126, IEA Clean Coal Centre, London

Nicholls D, Zerbe J (2012) Co-firing biomass and coal for fossil fuel reduction and other benefits-status of North American facilities in 2010, United States Department of Agriculture, General Technical Report PNWGTR-867

America Society for Testing and Materials (2011) ASTM D 3173-11: Standard test method for moisture in the analysis sample of coal and coke

America Society for Testing and Materials (2012) ASTM 3174-12: Standard test method for ash in the analysis sample of coal and coke from coal

America Society for Testing and Materials (2011) ASTM 3175-11: Standard test method for volatile matter in the analysis sample of coal and coke

Friedman H. L (1963) Kinetics of Thermal Degradation of Char forming Plastics from Thermogravimetric Application to a Phenolic Plastic. J Poly Sci part C, 6: p183–189.

Ozawa, T., A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn, 38(11), 1881–1886(1965).

Flynn J. H. and Wall L. A. (1966) General treatment of the thermogravimetry of polymers. J Res Natl Bur Stand-A Phys Chem. 70 A(6): 487–523

Coats A. W. and Redern J. P. (1964) Kinetics parameters from the thermogravimetric data. Nature (Lond), 201, 68–69

Kissinger HE (1957) Reaction kinetics in differential thermal analysis. Anal Chem, 29(11): 1702–1706

Reed TB, Gaur S (1995) An Atlas of Thermal Data of Biomass and Other Fuels, National Renewable Energy Laboratory/TP-433-7965

AI Calvo, LAC Tarelho, ER Teixeira, C Alves, T Nines, M Duarte, E Coz, D Custodio, A Castro, B Artinano, R Fraile (2013) Particulate emissions from the co-combustion of forest biomass and sewage sludge in a bubbling fluidised bed reactor. J of Fuel Process Technol, 114: 58–68

DL Urban, MJ Antal Jr (1982) Study of the kinetics of sewage sludge pyrolysis using DSC and TGA. Fuel, 61(9): 799–806

Jingai Shao, Rong Yan, Hanping Chen, Baowen Wang, Dong Ho Lee, David Tee Liang (2008) Pyrolysis characteristics and kinetics of sewage sludge by thermogravimetry fourier transform infrared analysis. J of Energy Fuels, 22(1): 38–45

R. Rodriguez, D. Gauthier, S. Udaquiola, G. Mazza, O. Martinez, G. Flamant (2008) Kinetic study and characterization of sewage sludge for its incineration J Environ Eng Sci, 7(3): 247–257.

D-W Kim, J-M Lee, J-S Kim, P-K Seon (2010) Study on the combustion characteristics of wood-pellet and Korean Anthracite Using TGA Korean. Chem Eng Res, 48(1): 58–67

Choi YS (2007) Coal/RDF Co-combustion in the Circulation Fluidized Bed Coal Boiler. J Korea Soc Waste Manage, 24(7): 598–603

Magdziarz A, Werle S (2014) Analysis of the combustion and pyrolysis of dried sewage sludge by TGA and MS. Waste Manage (Oxford) 34(2014):174–179

Fytili D, Zabaniotou A (2008) Utilization of sewage sludge in EU application of old and new methods—a review. Renew Sustain Energy Rev 12(2008):116–140

Yunbo Zhai Email author, Wenfeng Peng, Guangming Zeng, Zongming Fu, Yuanming Lan, Hongmei Chen, Chang Wang, Xiaopeng Fan (2012) Pyrolysis characteristics and kinetics of sewage sludge for different sizes and heating rates. J Therm Anal Calorim, 107(3): 1015–1022

R Dümpelmann, W Richarz, MR Stammbach (1991) Kinetic studies of the pyrolysis of sewage sludge by tga and comparison with fluidized beds. Can J Chem Eng, 69(4): 953–963

Acknowledgements

“This work is financially supported by Korea Ministry of Environment (MOE) as Waste to Energy Recycling Human Resource Development Project”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Im, H., Kim, C.G. Characterization of dried sewage sludge for co-firing in coal power plant by using thermal gravimetric analysis. J Mater Cycles Waste Manag 19, 1044–1051 (2017). https://doi.org/10.1007/s10163-016-0580-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-016-0580-2