Abstract

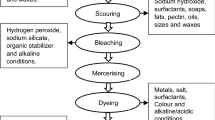

Textile effluents are characterized by high chemical oxygen demand, biological oxygen demand, total dissolved solids, pH and colour. Fabric preparation steps, such as desizing, scouring, bleaching and mercerizing, use various chemicals and plenty of water. The occurrence of unfixed dyes and other electrolytes in effluents poses serious threats to the environment. Available end-of-pipe treatment procedures are either expensive or not efficient; hence, a large number of small-scale industries succumb to this problem. So, finding an alternative eco-friendly process of textile production is of paramount interest. Here, we review three potential eco-friendly systems applicable to textile dyeing processes to minimize salt and water consumption. First, we review application of enzymatic processing in fabric preparation. Secondly, we review the use of biodegradable organic salts, such as trisodium citrate, magnesium acetate, tetrasodium edate and sodium salts of polycarboxylic acids, as fixation and exhaustion agents. Finally, we review various surface modifications of cotton to reduce the volume of effluent and total dissolved solids.

Similar content being viewed by others

References

Ahmed NSE (2005) The use of sodium edate in the dyeing of cotton with reactive dyes. Dyes Pigments 65(3):221–225. doi:10.1016/j.dyepig.2004.07.014

Battan B, Dhiman SS, Ahlawat S, Mahajan R, Sharma J (2011) Application of thermostable xylanase of Bacillus pumilus in textile processing. Indian J Microbiol 52(2):222–229. doi:10.1007/s12088-011-0118-1

Bhogle S (2007) Case study on wastewater disposal practices and likely treatment options in textile processing units in Tamil Nadu. TIDE, Bangalore

Burkinshaw SM, Lei XP, Lewis DM, Easton JR, Parton B, Phillips DAS (1990) Modification of cotton to improve its dyeability. Part II. Pretreating cotton with a thiourea derivative of polyamide–epichlorohydrin resins. J Soc Dyers Colour 106(10):307–315. doi:10.1111/j.1478-4408.1990.tb01227.x

Burkinshaw S, Mignanelli M, Froehling P, Bide M (2000) The use of dendrimers to modify the dyeing behaviour of reactive dyes on cotton. Dyes Pigments 47(3):259–267. doi:10.1016/S0143-7208(00)00053-X

Cavaco-Paulo A, Gübitz GM (2003) Textile processing with enzymes. Woodhead Publishing Limited, CRC Press, Cambridge

Chattopadhyay DP, Chavan RB, Sharma JK (2007) Salt-free reactive dyeing of cotton. Int J Cloth Sci Technol 19(2):99–108. doi:10.1108/09556220710725702

Costa SA, Tzanov T, Carneiro F, Gübitz GM, Cavaco-paulo A (2002) Recycling of textile bleaching effluents for dyeing using immobilized catalase. Biotechnol Lett 24(3):173–176. doi:10.1023/A:1014136703369

Dalvi P, Anthappan P, Darade N, Kanoongo N, Adivarekar R (2007) Amylase and pectinase from single source for simultaneous desizing and scouring. Indian J Fibre Text Res 32(4):459–465

Degani O, Gepstein S, Dosoretz CG (2002) Potential use of cutinase in enzymatic scouring of cotton fiber cuticle. Appl Biochem Biotechnol 102–103(1–6):277–289. doi:10.1385/ABAB:102-103:1-6:277

Eldefrawy NMH, Shaalan HF (2007) Integrated membrane solutions for green textile industries. Desalination 204(1–3):241–254. doi:10.1016/j.desal.2006.03.542

El-Shishtawy RM, Youssef YA, Ahmed NSE, Mousa AA (2007) The use of sodium edate in dyeing: II. Union dyeing of cotton/wool blend with hetero bi-functional reactive dyes. Dyes Pigments 72(1):57–65. doi:10.1016/j.dyepig.2005.07.017

Eren HA, Anis P, Davulcu A (2009) Enzymatic one-bath desizing—bleaching—dyeing process for cotton fabrics. Text Res J 79(12):1091–1098. doi:10.1177/0040517508099388

Etters JN (1999) Cotton preparation with alkaline pectinase: an environmental advance. Text Chem Color Am Dyestuff 1(3):33–36

Farha SAA, Gamal AM, Sallam HB, Mahmoud GEA, Ismail LFM (2010) Sodium edate and sodium citrate as an exhausting and fixing agents for dyeing cotton fabric with reactive dyes and reuse of dyeing effluent. J Am Sci 6(10):109–127

Fukuda T, Kato-Murai M, Kuroda K, Ueda M, Suye S-I (2008) Improvement in enzymatic desizing of starched cotton cloth using yeast codisplaying glucoamylase and cellulose-binding domain. Appl Microbiol Biotechnol 77(6):1225–1232. doi:10.1007/s00253-007-1263-7

Gamal AM, Farha SAA, Sallam HB, Mahmoud GEA, Ismail LFM (2010) Kinetic study and equilibrium isotherm analysis of reactive dyes adsorption onto cotton fiber. Nat Sci 8(11):95–110

Guan Y, Zheng Q, Mao Y, Gui M, Fu H (2007) Application of polycarboxylic acid sodium salt in the dyeing of cotton fabric with reactive dyes. J Appl Polym Sci 105(2):726–732. doi:10.1002/app.26091

Gunasekar V, Ponnusami V (2015) Eco-friendly textile dyeing processes. In: Lichtfouse et al (eds) Hydrogen production and remediation of carbon and pollutants. Environmental chemistry for a sustainable world, vol 6, pp 255–287. doi:10.1007/978-3-319-19375-5_6

Guthrie JD (1947) Introduction of amino groups into cotton fabric by use of 2-aminoethylsulfuric acid. Text Res J 17:625–629. doi:10.1177/004051754701701105

Hauser PJ, Tabba AH (2001) Improving the environmental and economic aspects of cotton dyeing using a cationised cotton. Color Technol 117:282–288. doi:10.1111/j.1478-4408.2001.tb00076.x

Hebeish A, Hashem M, Shaker N, Ramadan M, El-Sadek B, Hady MA (2009) New development for combined bioscouring and bleaching of cotton-based fabrics. Carbohydr Polym 78:961–972. doi:10.1016/j.carbpol.2009.07.019

Jakob B (1998) The removal of starch-based sizes. I. Enzymatic breakdown—more than just desizing. Melliand Textilberichte 79(7–8):523–527

Kaki J, Luttikhedde H, Nurmi K et al (2003) Type of cationic starch product, preparation thereof and its use. US. APP. 20030177915

Kitkulnumchai Y, Ajavakom A, Sukwattanasinitt M (2008) Treatment of oxidized cellulose fabric with chitosan and its surface activity towards anionic reactive dyes. Cellulose 15(4):599–608. doi:10.1007/s10570-008-9214-8

Lewis DM, Mcilroy KA (1997) The chemical modification of cellulosic fibres to enhance dyeability. Color Technol 27(1):5–17. doi:10.1111/j.1478-4408.1997.tb03770.x

Lim SH, Hudson SM (2004) Application of a fibre-reactive chitosan derivative to cotton fabric as a zero-salt dyeing auxiliary. Color Technol 120(3):108–113

Lim S-H, Lee JJ, Hinks D, Hauser P (2005) Bleaching of cotton with activated peroxide systems. Color Technol 121(2):89–95. doi:10.1111/j.1478-4408.2005.tb00258.x

Ma W, Zhang S, Tang B, Yang J (2005) Pretreatment of cotton with poly (vinylamine chloride) for salt-free dyeing with reactive dyes. Color Technol 121(4):193–197. doi:10.1111/j.1478-4408.2005.tb00272.x

Montazer M, Malek RMA, Rahimi A (2007) Salt free reactive dyeing of cationized cotton. Fibers Polym 8(6):608–612. doi:10.1007/BF02875997

Moore SB (1993) Low toxicity, biodegradable salt substitute for dyeing textiles: magnesium acetate in direct or reactive dyeing of cotton, pp 1–9. Patent number 5207800, United States

Nielsen PH, Kuilderd H, Zhou W, Lu X (2009) Enzyme biotechnology for sustainable textiles. In: Blackburn RS (ed) Sustainable textiles: life cycle and environmental impact. Woodhead Publishing Limited, New Delhi, pp 113–138

Ntuli F, Ikhu-omoregbe D, Kuipa PK, Muzenda E, Belaid M (2009) Characterization of effluent from textile wet finishing operations. In: Proceedings of the world congress on engineering and computer science I: WCECS ‘09, October 20–22, 2009, San Francisco, USA, Lecture notes in engineering and computer science, pp 69–74, Newswood Limited, 2009

Öner E, Sahinbaskan BY (2011) A new process of combined pretreatment and dyeing: REST. J Clean Prod 19(14):1668–1675. doi:10.1016/j.jclepro.2011.05.008

Patin A, Caballero G, Rodrı C, Patino A, Canal C, Rodriguez C, Navarro A, Canal JM (2011) Surface and bulk cotton fibre modifications: plasma and cationization. Influence on dyeing with reactive dye. Cellulose 18(4):1073–1083. doi:10.1007/s10570-011-9554-7

Periyasamy AP, Dhurai B, Thangamani K (2011) Salt-free dyeing—a new method of dyeing on lyocell/cotton blended fabrics with reactive dyes. Autex Res J 11(1):14–17

Ponnusami V, Srivastava SN (2009) Studies on application of teak leaf powders for the removal of color from synthetic and industrial effluents. J Hazard Mater 169(1–3):1159–1162. doi:10.1016/j.jhazmat.2009.03.142

Ponnusami V, Krithika V, Madhuram R, Srivastava SN (2007) Biosorption of reactive dye using acid-treated rice-husk: factorial design analysis. J Hazard Mater 142(1–2):397–403. doi:10.1016/j.jhazmat.2006.08.040

Ponnusami V, Lavanya N, Meenal M, Raj RAG, Srivastava SN (2008a) Application of nitric acid treated rice husk for sorption of reactive dye reactive black 5: analysis using statistical experimental design. Pollut Res 27(1):45–48

Ponnusami V, Vikram S, Srivastava SN (2008b) Guava (Psidium guajava) leaf powder: novel adsorbent for removal of methylene blue from aqueous solutions. J Hazard Mater 152(1):276–286. doi:10.1016/j.jhazmat.2007.06.107

Ponnusami V, Gunasekar V, Srivastava SN (2009) Kinetics of methylene blue removal from aqueous solution using gulmohar (Delonix regia) plant leaf powder: multivariate regression analysis. J Hazard Mater 169(1–3):119–127. doi:10.1016/j.jhazmat.2009.03.066

Prabhu KH, Karthikeyan N, Shyam Sundar P (2006) Combined bio-polishing and bleaching of cotton. Int Dyer 191:27–31

Prabu HG, Sundrarajan M (2002) Effect of the bio-salt trisodium citrate in the dyeing of cotton. Color Technol 118(3):131–134. doi:10.1111/j.1478-4408.2002.tb00370.x

Pratibha R, Malar P, Rajapriya T, Balapoornima S, Ponnusami V (2010) Statistical and equilibrium studies on enhancing biosorption capacity of Saccharomyces cerevisiae through acid treatment. Desalination 264:102–107

Ramasamy R, Abdelbagi H, Ahmed M, Karthik SS (2012) Development of microbial consortium for the biodegradation and biodecolorization of textile effluents. J Urban Env Eng 6(1):36–41. doi:10.4090/juee.2012.v6n1.036041

Saravanan D, Ramachandran T (2007) Efficiency and evaluation of amylases in desizing. Asian Dyer 4(6):64–67

Sawada K, Ueda M (2001) Enzyme processing of textiles in reverse micellar solution. J Biotechnol 89(2–3):263–269. doi:10.1016/S0168-1656(01)00310-8

Shafie AE, Fouda MMG, Hashem M (2009) One-step process for bio-scouring and peracetic acid bleaching of cotton fabric. Carbohydr Polym 78(2):302–308. doi:10.1016/j.carbpol.2009.04.002

Sheth GN, Musaie A (2003) Application of biotechnology to desizing of cotton fabrics. BTRA Scan 33(2):18–21

Špička N, Tavčer PF (2011) Glucose oxidases—potential enzymes for bleaching textile fibres. Tekstilec 54(1–3):16–29

Tanapongpipat A, Khamman C, Pruksathorm K, Hunsom M (2008) Process modification in the scouring process of textile industry. J Clean Prod 16(1):152–158. doi:10.1016/j.jclepro.2006.06.016

Teng X, Ma W, Zhang S (2010) Application of tertiary amine cationic polyacrylamide with high cationic degree in salt-free dyeing of reactive dyes. Chin J Chem Eng 18(6):1023–1028. doi:10.1016/S1004-9541(09)60163-4

Tian L, Branford-white C, Wang W, Nie H, Zhu L (2012) Laccase-mediated system pretreatment to enhance the effect of hydrogen peroxide bleaching of cotton fabric. Int J Biol Macromol 50(3):782–787. doi:10.1016/j.ijbiomac.2011.11.025

Tzanov T, Calafell M, Guebitz GM, Cavaco-Paulo A (2001) Bio-preparation of cotton fabrics. Enzym Microb Technol 29(6–7):357–362. doi:10.1016/S0141-0229(01)00388-X

Tzanov T, Costa SA, Gübitz GM, Cavaco-Paulo A (2002) Hydrogen peroxide generation with immobilized glucose oxidase for textile bleaching. J Biotechnol 93(1):87–94. doi:10.1016/S0168-1656(01)00386-8

Tzanov T, Basto C, Gübitz GM, Cavaco-Paulo A (2003) Laccases to improve the whiteness in a conventional: bleaching of cotton. Macromol Mater Eng 288(10):807–810. doi:10.1002/mame.200300100

Wang H, Lewis DM (2002) Chemical modification of cotton to improve fibre dyeability. Color Technol 118(4):159–168. doi:10.1111/j.1478-4408.2002.tb00094.x

Wang Q, Fan X, Hua Z, Gao W, Chen J (2007) Degradation kinetics of pectins by an alkaline pectinase in bioscouring of cotton fabrics. Carbohydr Polym 67(4):572–575. doi:10.1016/j.carbpol.2006.06.031

Wei MA, Shu-fen Z, Jin-zong Y (2005) Development of functional polymers in modification of cotton for improving dyeability of reactive dyes. In: Proceedings of the 3rd international conference on functional molecules, pp 69–75

Wu TS, Chen KM (1992) New cationic agents for improving the dyeability of cellulose fibres. Part 1—pretreating cotton with polyepichlorohydrin-amine polymers for improving dyeability with direct dyes. J Soc Dyers Colour 108(9):388–394. doi:10.1111/j.1478-4408.1992.tb01486.x

Wu TS, Chen KM (1993) New cationic agents for improving the dyeability of cellulose fibres. Part 2—pretreating cotton with polyepichlorohydrin-amine polymers for improving dyeability with reactive dyes. J Soc Dyers Colour 109(4):153–158. doi:10.1111/j.1478-4408.1993.tb01547.x

Zhang S, Ma W, Ju B, Dang N, Zhang M (2005) Continuous dyeing of cationised cotton with reactive dyes. Color Technol 121(4):183–186

Zhang F, Chen Y, Lin H, Lu Y (2007) Synthesis of an amino-terminated hyperbranched polymer and its application in reactive dyeing on cotton as a salt-free dyeing auxiliary. Color Technol 123(6):351–357. doi:10.1111/j.1478-4408.2007.00108.x

Zhang F, Chen Y, Lin H, Wang H, Zhao B (2008) HBP-NH2 grafted cotton fiber: preparation and salt-free dyeing properties. Carbohydr Polym 74(2):250–256. doi:10.1016/j.carbpol.2008.02.006

Zhigang H (2008) Chitosan nanoparticles for functional textile finishes. The Hong Kong Polytechnic University. http://hdl.handle.net/10397/3949

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Varadarajan, G., Venkatachalam, P. Sustainable textile dyeing processes. Environ Chem Lett 14, 113–122 (2016). https://doi.org/10.1007/s10311-015-0533-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10311-015-0533-3