Abstract

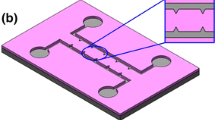

Polymer micro- and nanofluidic chips become increasingly significant for medical and biological applications. However, it is difficult to fabricate micro- and nanochannels integrately into a polymer substrate due to the reflow and insufficient flow of the polymer. In the present paper, micro- and nanochannels were hot embossed into a multilayer substrate by micromold and nanomold, respectively. To replicate high replication precision nanochannels without damaging the fabricated microchannels, the embossing parameters were optimized by Taguchi and analytic hierarchy process methods. The fabricated micro- and nanochannels were fully sealed at bonding parameters optimized according to the bonding rate of the chip. The fluorescence image indicates that there is no blocking or leakage over the entire micro- and nanochannels. With presented fabrication method, low-cost polymer micro- and nanostructures can be fabricated, which allows for commercial manufacturing of micro- and nanofluidic chips.

Similar content being viewed by others

References

Chantiwas R et al (2011) Flexible fabrication and applications of polymer nanochannels and nanoslits. Chem Soc Rev 40(7):3677–3702

Cheng E et al (2014) Experimental and numerical study on deformation behavior of polyethylene terephthalate two-dimensional nanochannels during hot embossing process. J Micromech Microeng 24(1):015004

Chiu SH et al (2017) Multi-objective optimization of process parameters in an area-forming rapid prototyping system using the Taguchi method and a grey relational analysis. Proc Inst Mech Eng B J Eng Manuf 231(12):2211–2222

Cho YH et al (2009) Fabrication of high-aspect-ratio polymer nanochannels using a novel Si nanoimprint mold and solvent-assisted sealing. Microfluid Nanofluid 9(2–3):163–170

Chong KSL, Lee Y-Y, Low HY (2011) Recessed area patterning via nanoimprint lithography. J Vac Sci Technol B 29(6):060602

Chun DW et al (2013) Fast myoglobin detection using nanofluidic electrokinetic trapping technique. Appl Phys Express 6(1):017001

Dong S-H, Zhang J, Ge S-X (2016) Microfluidic chips for cell capturing and separation. Prog Biochem Biophys 43(11):1102–1110

Du L et al (2012) A method of water pretreatment to improve the thermal bonding rate of PMMA microfluidic chip. Microsyst Technol Micro Nanosyst Inf Storage Process Syst 18(4):423–428

Fanzio P et al (2011) DNA detection with a polymeric nanochannel device. Lab Chip 11(17):2961–2966

Gillespie D, Pennathur S (2013) Separation of ions in nanofluidic channels with combined pressure-driven and electro-osmotic flow. Anal Chem 85(5):2991–2998

Hlushkou D et al (2012) Propagating concentration polarization and ionic current rectification in a nanochannel-nanofunnel device. Anal Chem 84(1):267–274

Levy SL et al (2008) Entropic unfolding of DNA molecules in nanofluidic channels. Nano Lett 8(11):3839–3844

Li S-H (2013) Research on evaluation system of new energy vehicles based on AHP. Trans Tech Publications, Malaysia

Mohammadi F, Mohammadi T (2017) Optimal conditions of porous ceramic membrane synthesis based on alkali activated blast furnace slag using Taguchi method. Ceram Int 43(16):14369–14379

Okuda K et al (2007) Micro-nano mixture patterning by thermal-UV novel nanoimprint. J Vac Sci Technol B 25(6):2370–2372

Pedersen JN et al (2013) Fully streched single DNA molecules in a nanofluidic chip show large-scale structural variation. Biophys J 104(2):175A

Rong Y et al (2009) Fabrication of micro/nano fluidic channels by nanoimprint lithography and bonding using SU-8. Microelectron Eng 86(4–6):1379–1381

Sang J et al (2013) Protein sensing by nanofluidic crystal and its signal enhancement. Biomicrofluidics 7(2):024112

Scaffaro R, Sutera F, Lopresti F (2017) Using Taguchi method for the optimization of processing variables to prepare porous scaffolds by combined melt mixing/particulate leaching. Mater Des 131:334–342

Schoch RB, Han J, Renaud P (2008) Transport phenomena in nanofluidics. Rev Mod Phys 80(3):839–883

Takagi H et al (2008) Analysis of time dependent polymer deformation based on a viscoelastic model in thermal imprint process. Microelectron Eng 85(5–6):902–906

Thamdrup LH, Klukowska A, Kristensen A (2008) Stretching DNA in polymer nanochannels fabricated by thermal imprint in PMMA. Nanotechnology 19(12):125301

Tsukahara T (2010) Nanofluidic-based separation system of radionuclide ions by controlling electrostatic forces. Bull Res Lab Nucl React 34(1):51

van Kan JA et al (2012) High throughput fabrication of disposable nanofluidic lab-on-chip devices for single molecule studies. Biomicrofluidics 6(3):036502

Viefhues M, Regtmeier J, Anselmetti D (2012) Nanofluidic devices for dielectrophoretic mobility shift assays by soft lithography. J Micromech Microeng 22(11):115024

Wang X, Li Y, Cui W (2012) Design and implementation of a collaboration-based AHP evaluation system. IEEE Computer Society, Wuhan

Xing C, Guo LJ (2004) One-step lithography for various size patterns with a hybrid mask-mold. Microelectron Eng 71(3–4):288–293

Xudi W et al (2009) Fabrication of enclosed nanofluidic channels by UV cured imprinting and optimized thermal bonding of SU-8 photoresist. Microelectron Eng 86(4–6):1347–1349

Yasui T et al (2011) DNA separation in nanowall array chips. Anal Chem 83(17):6635–6640

Yin Z, Cheng E, Zou H (2014) A novel hybrid patterning technique for micro and nanochannel fabrication by integrating hot embossing and inverse UV photolithography. Lab Chip 14(9):1614–1621

Zhang X, Li L, Luo C (2016) Gel integration for microfluidic applications. Lab Chip 16(10):1757–1776

Acknowledgements

This project is supported by Specialized Research Fund for the Doctoral Program of Higher Education of China (SRFDP) (No. 20120041110034) and National Natural Science Foundation of China (No. 51705198).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yin, Z., Zou, H. Multilayer patterning technique for micro- and nanofluidic chip fabrication. Microfluid Nanofluid 21, 174 (2017). https://doi.org/10.1007/s10404-017-2013-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-017-2013-5