Abstract

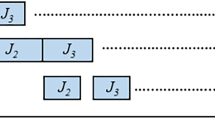

We are interested in the problem of scheduling orders for different product types in a facility with a number of machines in parallel. Each order asks for certain amounts of various different product types which can be produced concurrently. Each product type can be produced on a subset of the machines. Two extreme cases of machine environments are of interest. In the first case, each product type can be produced on one and only one machine which is dedicated to that product type. In the second case, all machines are identical and flexible; each product type can be produced by any one of the machines. Moreover, when a machine in this case switches over from one product type to another, no setup is required. Each order has a release date and a weight. Preemptions are not allowed. The objective is minimizing the total weighted completion time of the orders. Even when all orders are available at time 0, both types of machine environments have been shown to be NP-hard for any fixed number (≥2) of machines. This paper focuses on the design and analysis of approximation algorithms for these two machine environments. We also present empirical comparisons of the various algorithms. The conclusions from the empirical analyses provide insights into the trade-offs with regard to solution quality, speed, and memory space.

Similar content being viewed by others

References

Blocher, J., & Chhajed, D. (1996). The customer order lead-time problem on parallel machines. Naval Research Logistics, 43, 629–654.

Coffman, E. G., Garey, M. R., & Johnson, D. S. (1978). An application of bin-packing to multiprocessor scheduling. SIAM Journal on Computing, 7, 1–17.

Grötschel, M., Lovasz, L., & Schrijver, A. (1993). Geometric algorithms and combinatorial optimization. Berlin: Springer.

Hall, L. A., Schulz, A. S., Shmoys, D. B., & Wein, J. (1997). Scheduling to minimize average completion time: off-line and on-line approximation algorithms. Mathematics of Operations Research, 22, 513–544.

Leung, J. Y.-T., Li, H., & Pinedo, M. (2005a). Order scheduling in an environment with dedicated resources in parallel. Journal of Scheduling, 8, 355–386.

Leung, J. Y.-T., Li, H., & Pinedo, M. (2005b). Order scheduling models: an overview. In G. Kendall, E. Burke, S. Petrovic & M. Gendreau (Eds.), Multidisciplinary scheduling: theory and applications (pp. 37–53). Berlin: Springer.

Leung, J. Y.-T., Li, H., & Pinedo, M. (2006a). Scheduling orders for multiple product types with due date related objectives. European Journal of Operational Research, 168, 370–389.

Leung, J. Y.-T., Li, H., & Pinedo, M. (2006b). Approximation algorithms for minimizing total weighted completion time of orders on identical machines in parallel. Naval Research Logistics, 53, 243–260.

Leung, J. Y.-T., Li, H., & Pinedo, M. (2007). Scheduling orders for multiple product types to minimize total weighted completion time. Discrete Applied Mathematics, 155, 945–970.

Li, H. (2005). Order scheduling in dedicated and flexible machine environments. Ph.D. Thesis, Department of Computer Science, New Jersey Institute of Technology, Newark, New Jersey.

Makhorin, A. (2004). GNU linear programming kit: reference manual (version 4.4).

Ng, C., Cheng, T., & Yuan, J. (2003). Concurrent open shop scheduling to minimize the weighted number of tardy jobs. Journal of Scheduling, 6, 405–412.

Queranne, M. (1993). Structure of a simple scheduling polyhedron. Mathematical Programming, 58, 263–285.

Sung, C., & Yoon, S. (1998). Minimizing total weighted completion time at a pre-assembly stage composed of two feeding machines. International Journal of Production Economics, 54, 247–255.

Wang, G., & Cheng, T. (2003). Customer order scheduling to minimize total weighted completion time. In Proceedings of the 1st multidisciplinary international conference on scheduling: theory and applications (pp. 409–416). Nottingham, United Kingdom.

Yang, J., & Posner, M. E. (2005). Scheduling parallel machines for the customer order problem. Journal of Scheduling, 8, 49–74.

Author information

Authors and Affiliations

Corresponding author

Additional information

This research is supported by the National Science Foundation through grants DMI-0300156 and DMI-0245603.

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Leung, J.YT., Li, H. & Pinedo, M. Scheduling orders on either dedicated or flexible machines in parallel to minimize total weighted completion time. Ann Oper Res 159, 107–123 (2008). https://doi.org/10.1007/s10479-007-0270-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-007-0270-5