Abstract

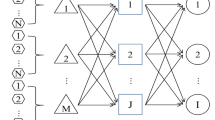

Performance evaluation is of great importance for effective supply chain management. The foundation of efficiency evaluation is to faithfully identify the corresponding production possibility set. Although a lot of researches have been done on supply chain DEA models, the exact definition for supply chain production possibility set is still in absence. This paper defines two types of supply chain production possibility sets, which are proved to be equivalent to each other. Based upon the production possibility set, a supply chain CRS DEA model is advanced to appraise the overall technical efficiency of supply chains. The major advantage of the model lies on the fact that it can help to find out the most efficient production abilities in supply chains, by replacing or improving inefficient subsystems (supply chain members). The proposed model also directly identifies the benchmarking units for inefficient supply chains to improve their performance. A real case validates the reasonableness and acceptability of this approach.

Similar content being viewed by others

References

Altiok, T., & Ranjan, R. (1995). Multi-stage, pull-type production/inventory systems. IIE Transactions, 27, 190–200.

China Construction Bank (Anhui Branch) (2004). Annual report 2004 of China Construction Bank in Anhui Province (in Chinese).

Camm, J. D., Chorman, T. E., Dull, F. A., Evans, J. R., Sweeney, D. J., & Wegryn, G. W. (1997). Blending OR/MS, judgment, and GIS: restructuring P&G’s supply chain. Interfaces, 27(1), 128–142.

Castelli, L., Pesenti, R., & Ukovich, W. (2004). DEA-like models for the efficiency evaluation of hierarchically structured units. European Journal of Operational Research, 154, 465–476.

Charnes, A., Cooper, W. W., & Rhodes, E. (1978). Measuring the efficiency of decision making units. European Journal of Operational Research, 2(6), 429–444.

Chen, Y., Liang, L., & Yang, F. (2006). A DEA game model approach to supply chain efficiency. Annals of Operations Research, 1451, 5–13.

Clarke, R. L., & Gourdin, K. N. (1991). Measuring the efficiency of the logistics process. Journal of Business Logistics, 122, 17–33.

Cohen, M. A., & Lee, H. L. (1989). Resource deployment analysis of global manufacturing and distribution networks. Journal of Manufacturing and Operations Management, 2, 81–104.

Easton, L., Murphy, D. J., & Pearson, J. N. (2002). Purchasing performance evaluation:with data envelopment analysis. European Journal of Purchasing & Supply Management, 8, 123–134.

Färe, R., & Grosskopf, S. (2000). Network DEA. Socio-Economic Planning Sciences, 341, 35–49.

Golany, B., Hackman, S. T., & Passy, U. (2003). An efficiency measurement framework for multi-stage production systems. Annals of Operations Research, 1451, 51–68.

Ishii, K., Takahashi, K., & Muramatsu, R. (1988). Integrated production, inventory and distribution systems. International Journal of Production Research, 263, 473–482.

Lee, H. L., & Billington, C. (1993). Material management in decentralized supply chains. Operations Research, 41, 835–847.

Lewis, H. F., & Sexton, T. R. (2004). Network DEA: efficiency analysis of organizations with complex internal structure. Computers and Operations Research, 319, 1365–1410.

Liang, L., Yang, F., Cook, W. D., & Zhu, J. (2006). DEA models for supply chain efficiency evaluation. Annals of operation research, 1451, 35–49.

Lothgren, M., & Tambour, M. (1999). Productivity and customer satisfaction in Swedish pharmacies:A DEA network model. European Journal of Operational Research, 115, 449–458.

Narasimhan, R., Talluri, S., & Das, A. (2004). Exploring flexibility and execution competencies of manufacturing firms. Journal of Operations Management, 22, 91–106.

Newhart, D. D., Stott, K. L., & Vasko, F. J. (1993). Consolidating production sizes to minimize inventory levels for a multi-stage production and distribution systems. Journal of the Operational Research Society, 447, 637–644.

Ross, A., & Droge, C. (2002). An integrated benchmarking approach to distribution center performance using DEA modeling. Journal of Operations Management, 20, 19–32.

Ross, A., & Droge, C. (2004). An analysis of operations efficiency in large-scale distribution systems. Journal of Operations Management, 21, 673–688.

Talluri, S., & Baker, R. C. (2002). A multi-phase mathematical programming approach for effective supply chain design. European Journal of Operational Research 141(3), 546–560. This paper is ranked 21 in highly requested papers in EJOR from April 2002–April 2004 with 1,114 requests.

Troutt, M. D., Ambrose, P., & Chan, C. K. (2001). Optimal throughput for multistage input-output processes. International Journal of Operations and Production Management, 21(1), 148–158.

Troutt, M. D., Ambrose, P., & Chan, C. K. (2004). Multi-stage efficiency tools for goal setting and monitoring in supply chains. In C. K. Chan & H. W. J. Lee (Eds.), Successful strategies in supply chain management Hershey: Idea Group Publishing Co.

Voudouris, V. T. (1996). Mathematical programming techniques to debottleneck the supply chain of fine chemical industries. Computers and Chemical Engineering, 20, S1269–S1274.

Weber, C. A., & Desai, A. (1996). Determinants of paths to vendor market efficiency using parallel coordinates representation:a negotiation tool for buyers. European Journal of Operational Research, 90, 142–155.

Wu, D. (2008). A note on dea efficiency assessment using ideal point: an improvement of Wang and Luo’s model. Applied Mathematics and Computation, 183(2), 819–830.

Wu, D. (2009). Performance evaluation: an integrated method using data envelopment analysis and fuzzy preference relations. European Journal of Operational Research, 194(1), 227–235.

Wu, D., & Olson, D. L. (2008). A comparison of stochastic dominance and stochastic DEA for vendor evaluation. International Journal of Production Research, 46, 2313–2327.

Wu, D., Yang, Z., & Liang, L. (2006). Using DEA-neural network approach to evaluate branch efficiency of a large Canadian Bank. Expert Systems with Applications 31(1), 108–115.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, F., Wu, D., Liang, L. et al. Supply chain DEA: production possibility set and performance evaluation model. Ann Oper Res 185, 195–211 (2011). https://doi.org/10.1007/s10479-008-0511-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-008-0511-2