Abstract

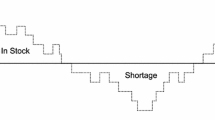

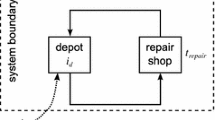

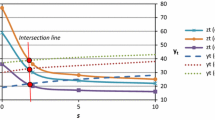

In this paper, we study the capacity flexibility problem of a maintenance service provider, who is running a repair shop and is responsible for the availability of numerous specialized systems which contain a critical component that is prone to failure. Upon a critical component failure, the component is sent to the repair shop and the service provider is responsible for the repair as well as the down-time costs resulting from the system unavailability. In order to decrease the down-time costs, the repair shop keeps an inventory for the critical components, such that a failed critical component can be replaced with a spare one immediately, if it is available. The component inventory stock level and the repair shop capacity level decisions have to be taken jointly by the service provider. The shop floor manager resorts to two different capacity modes in order to make use of capacity flexibility. First one is the single-level capacity mode, in which the capacity level is fixed and is the only capacity related decision. The best results in this mode serve as a reference to the two-level capacity mode, in which there are low (permanent) and high (permanent plus contingent) capacity levels. In this mode, the permanent capacity is always available in the shop, whereas the deployment of the contingent capacity is decided at the start of each period based on the number of components waiting to be repaired in the shop. The relevant capacity decisions of this mode are the permanent and contingent capacity levels, the period length and the states (in terms of number of failed components waiting) where the contingent capacity is deployed. We develop quantitative models based on queuing theory that integrate the inventory level decision with the capacity related decisions for the repair shop, in each of the two capacity modes, in order to minimize the total cost rate of the service provider. Our numerical results suggest that two-level capacity mode can bring substantial savings compared to the best fixed capacity mode and these savings are mostly resulting from lower repair shop capacity usage. Moreover, we find that the system, in most cases, chooses the shortest period length possible, indicating the overarching importance of a fast response to the system state. The system switches to the high capacity mode if the spare part stock is just one or two, then it uses a quite high contingent capacity level, in order to avoid out of stock. If contingent capacity costs are high, system chooses a high level of permanent capacity to prevent frequent capacity switches.

Similar content being viewed by others

References

Albright, S. C., & Gupta, A. (1993). Steady-state approximation of a multiechelon multi-indentured repairable-item inventory system with a single repair facility. Naval Research Logistics, 40(4), 479–493.

Albright, S. C., & Soni, A. (1988). Markovian multiechelon repairable inventory system. Naval Research Logistics, 35(1), 49–61.

Alp, O., & Tan, T. (2008). Tactical capacity management under capacity flexibility. IIE Transactions, 40(3), 221–237.

Altiok, T. (1997). Performance analysis of manufacturing systems. New York: Springer.

Bekker, R., Borst, S. C., Boxma, O. J., & Kella, O. (2004). Queues with workload-dependent arrival and service rates. Queueing Systems, 46(3/4), 537–556.

Bradley, J. R., & Glynn, P. W. (2002). Managing capacity and inventory jointly in manufacturing systems. Management Science, 48(2), 273–288.

Buyukkaramikli, N. C., Bertrand, J. W. M., & Ooijen, H. P. G. (2013a). Periodic capacity management under a lead-time performance constraint. OR Spektrum, 35(1), 221–249.

Buyukkaramikli, N. C., Bertrand, J. W. M., & Ooijen, H. P. G. (2013b). Flexible hiring in a make to order system with parallel processing units. Annals of Operations Research, 203(1), 159–178.

Buyukkaramikli, N. C., Gurler, U., & Alp, O. (2013c). Coordinated logistics: joint replenishment with capacitated transportation for a supply chain. Production and Operations Management. doi:10.1111/poms.12041.

Buzacott, J. A., & Shanthikumar, G. J. (1993). Stochastic models of manufacturing systems. Englewood Cliffs: Prentice-Hall.

Diaz, A., & Fu, M. C. (1997). Models for multi-echelon repairable item inventory systems with limited repair capacity. European Journal of Operational Research, 97(3), 480–492.

Feeney, G. J., & Sherbrooke, C. C. (1966). The (s−1,s) inventory policy under compound Poisson demand. Management Science, 12(5), 391–411.

Fu, M. C., Marcus, S. I., & Wang, I.-j. (2000). Monotone optimal policies for a transient queueing staffing problem. Operations Research, 48(2), 327–331.

Gross, D., Miller, D. R., & Soland, R. M. (1983). A closed queueing network model for multi-echelon repairable item provisioning. IIE Transactions, 15(4), 344–352.

De Haas, H. F. M. (1995). The coordination of initial stock and flexible manpower in repairable item systems. PhD thesis, Eindhoven, TU/e.

Holt, C. C., Modigliani, F., Muth, J. F., & Simon, H. A. (1960). Planning Production, Inventories and Work Force. Englewood Cliffs: Prentice-Hall.

Keizers, J. M., Bertrand, J. W. M., & Wessels, J. (2009). Diagnosing order planning performance at a navy maintenance and repair organization, using logistic regression. Production and Operations Management, 12(4), 445–463.

Kouvelis, P., & Milner, J. M. (2002). Supply chain capacity and outsourcing decisions: the dynamic interplay of demand and supply uncertainty. IIE Transactions, 34(8), 717–728.

Kulkarni, V. G. (1995). Modeling and analysis with stochastic systems. London: Chapman& Hall.

Ledermann, W., & Reuter, G. E. H. (1954). Spectral theory for the differential equations of simple birth and death processes. Philosophical Transactions - Royal Society. Mathematical, Physical and Engineering Sciences, 246(914), 321–369.

Lippman, S. A. (1975). Applying a new device in the optimization of exponential queuing systems. Operations Research, 23(4), 687–710.

Mieghem, J. A. Van (1999). Coordinating investment, production and subcontracting. Management Science, 45(7), 954–971.

Milner, J. M., & Pinker, E. J. (2001). Contingent demand labor and contracting under supply uncertainty. Management Science, 47(8), 1046–1062.

Muckstadt, J. A. (2005). Analysis and Algorithms for Service Parts Supply Chains. Springer Series in Operations Research and Financial Engineering. Berlin: Springer.

Neuts, M. F. (1981). Matrix-geometric solutions in stochastic models—an algorithmic approach. Baltimore: John Hopkins Press.

Oliva, R., & Kallenberg, R. (2003). Managing the transition from products to services. International Journal of Service Industry Management, 14(2), 160–172.

Perlman, Y., Mehrez, A., & Kaspi, M. (2001). Setting expediting repair policy in a multi-echelon repairable-item inventory system with limited repair capacity. Journal of the Operational Research Society, 52(2), 198–209.

Pinker, E. J., & Larson, R. C. (2003). Optimizing the use of contingent labor when demand is uncertain. European Journal of Operational Research, 144(1), 39–55.

Puterman, M. L. (1994). Markov decision processes—discrete stochastic dynamic programming. New York: Wiley.

Rosen, S. (1986). Chapter 12: The theory of equalizing differences. In Handbook of labor economics (pp. 641–692).

Safaei, N., Banjevic, D., & Jardine, A. K. S. (2011). Workforce-constrained maintenance scheduling for military aircraft fleet: a case study. Annals of Operations Research, 186(1), 295–316.

Scudder, G. D., & Hausman, W. H. (1982). Spares stocking policies for repairable items with dependent repair times. Naval Research Logistics Quarterly, 29(2), 303–322.

Sennott, L. I. (1998). Stochastic dynamic programming and the control of queueing systems (1st ed.). New York: Wiley-Interscience.

Sherbrooke, C. (1992). Optimal inventory modeling of systems. New York: Wiley.

Sleptchenko, A., van der Heijden, M. C., & van Harten, A. (2003). Trade-off between inventory and repair capacity in spare part networks. Journal of the Operational Research Society, 54, 263–272.

Stern, T. (1979). Approximations of queue dynamics and their application to adaptive routing in computer communication networks. IEEE Transactions on Communications, 27(9), 1331–1335.

Tan, B., & Gershwin, S. B. (2004). Production and subcontracting strategies for manufacturers with limited capacity and volatile demand. Annals of Operations Research, 125(1–4), 205–232. http://link.springer.com/10.1023/B:ANOR.0000011192.23903.7f (11 November 2013).

Yoo, J. (1996). Queueing models for staffing service operations. PhD thesis, College Park, University of Maryland.

Zijm, W. H., & Avsar, Z. M. (2003). Capacitated two-indenture models for repairable item systems. International Journal of Production Economics, 81–82, 573–588.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Buyukkaramikli, N.C., van Ooijen, H.P.G. & Bertrand, J.W.M. Integrating inventory control and capacity management at a maintenance service provider. Ann Oper Res 231, 185–206 (2015). https://doi.org/10.1007/s10479-013-1506-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-013-1506-1