Abstract

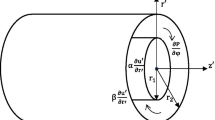

Boundary slippage is used to generate the load-carrying capacity of the hydrodynamic contact between two parallel plane surfaces. In the fluid inlet zone, the fluid-contact interfacial shear strength on a stationary surface is set at low to generate boundary slippage there, while in the fluid outlet zone the fluid-contact interfacial shear strength on the stationary surface is set at high enough to prevent the occurrence of boundary slippage. The fluid-contact interfacial shear strength on the entire moving surface is set at high enough to prevent boundary slippage on the moving surface. These hydrodynamic contact configurations are analyzed to generate the pronounced load-carrying capacity. The optimum ratio of the outlet zone width to the inlet zone width for the maximum load-carrying capacity of the whole contact is found to be 0.5.

Similar content being viewed by others

Abbreviations

- c 1 :

-

integral constant

- c 2 :

-

integral constant

- G :

-

3ψ/(1 + 4ψ)(1 + ψ)

- h :

-

fluid film thickness

- H :

-

dimensionless fluid film thickness

- l 1 :

-

width of the “A” sub-zone

- l 2 :

-

width of the “B” sub-zone

- p :

-

fluid pressure

- p max :

-

maximum fluid pressure

- P max :

-

dimensionless maximum fluid pressure

- q :

-

fluid mass flow through the contact per unit contact length

- q v :

-

fluid volume flow through the contact per unit contact length

- u :

-

sliding speed between two surfaces

- U :

-

dimensionless sliding speed between two surfaces

- ū a :

-

fluid film velocity at the top boundary

- u a :

-

speed of the upper contact surface

- ū b :

-

fluid film velocity at the bottom boundary

- u b :

-

speed of the lower contact surface

- w :

-

carried load per unit contact length

- w max :

-

maximum carried load per unit contact length

- W :

-

dimensionless load per unit contact length of the contact

- x :

-

coordinate shown in Fig. 1

- ρ :

-

fluid density

- λ 1 :

-

3τ sa/2h − 3uη/h 2 − 3q v η/h 3

- λ 2 :

-

−6uη/h 2 − 12q v η/h 3

- ψ :

-

l1/l2

- η :

-

fluid viscosity

- τa, τb:

-

shear stresses at the top and bottom boundaries respectively

- τ a,A :

-

shear stress at the top boundary in the “A” sub-zone

- τ b,B :

-

shear stress at the bottom boundary in the “B” sub-zone

- τ sa :

-

fluid-contact interfacial shear strength in the “B” sub-zone at the top boundary

- τ sa,A :

-

fluid-contact interfacial shear strength at the upper plane surface in the “A” subzone

- τ sb :

-

fluid-contact interfacial shear strength at the lower plane surface

- Δu a :

-

fluid slipping velocity at the top boundary in the “B” sub-zone

- \( \bar \tau \)a,A, \( \bar \tau \)b,B:

-

dimensionless fluid-contact interfacial shear stresses respectively

References

Zhang Y B. Mixed rheologies in elastohydrodynamic lubrication[J]. Industrial Lubrication and Tribology, 2004, 56(2):88–106.

Zhang Y B, Wen S. A lubrication deviation from the classical EHL theory by the lubricant viscoplasticity: Part I-Film thickness dependence[J]. Tribology Transactions, 2001, 44(2):224–232.

Zhang Y B, Wen S. A lubrication deviation from the classical EHL theory by the lubricant viscoplasticity: Part II-Boundary of lubrication regimes[J]. Tribology Transactions, 2001, 44(2):305–309.

Zhang Y B, Wen S. An analysis of elastohydrodynamic lubrication with limiting shear stress: Part I-Theory and solutions[J]. Tribology Transactions, 2002, 45(2):135–144.

Zhang Y B. Contact-fluid interfacial shear strength and its critical importance in elastohydrodynamic lubrication[J]. Industrial Lubrication and Tribology, 2006, 58(1):4–14.

Zhang Y B. Contact-fluid interfacial slippage in hydrodynamic lubricated contacts[J]. Journal of Molecular Liquids, 2006, 128(9):99–104.

Ehret P, Dowson D, Taylor C M. On lubricant transport conditions in elastohydrodynamic conjunctions[J]. Proceedings of Royal Society of London, 1998, A454(7):763–787.

Jacobson B J, Hamrock B J. Non-Newtonian fluid model incorporated into elastohydrodynamic lubrication of rectangular contacts[J]. Journal of Tribology, ASME, 1984, 106(2):275–284.

Shieh J, Hamrock B J. Film collapse in EHL and micro-EHL[J]. Journal of Tribology, ASME, 1991, 113(2):372–377.

Zhang Y B, Wen S. EHL film thickness limitation theory under a limiting shear stress[J]. Tribology Transactions, 2002, 45(4):531–539.

Kaneta M, Nishikawa H, Kanada T, Matsuda K. Abnormal phenomena appearing in EHL contacts[J]. Journal of Tribology, ASME, 1996, 118(4):886–892.

Guo F, Wong P L. An anomalous elastohydrodynamic lubrication film: inlet dimple[J]. Journal of Tribology, ASME, 2005, 127(2):425–434.

Fu Z, Guo F, Wong P L. Non-classical elastohydrodynamic lubricating film shape under large slide-roll ratios[J]. Tribology Letters, 2007, 27(2):211–219.

Yagi K, Kyogoku K, Nakahara T. Relationship between temperature distribution in EHL film and dimple formation[J]. ASME Journal of Tribology, 2005, 127(3):658–665.

Pinkus O, Sternlicht B. Theory of hydrodynamic lubrication[M]. New York: McGraw-Hill, 1961.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by ZHOU Zhe-wei

Rights and permissions

About this article

Cite this article

Zhang, Yb. Boundary slippage for generating hydrodynamic load-carrying capacity. Appl. Math. Mech.-Engl. Ed. 29, 1155–1164 (2008). https://doi.org/10.1007/s10483-008-0905-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10483-008-0905-y